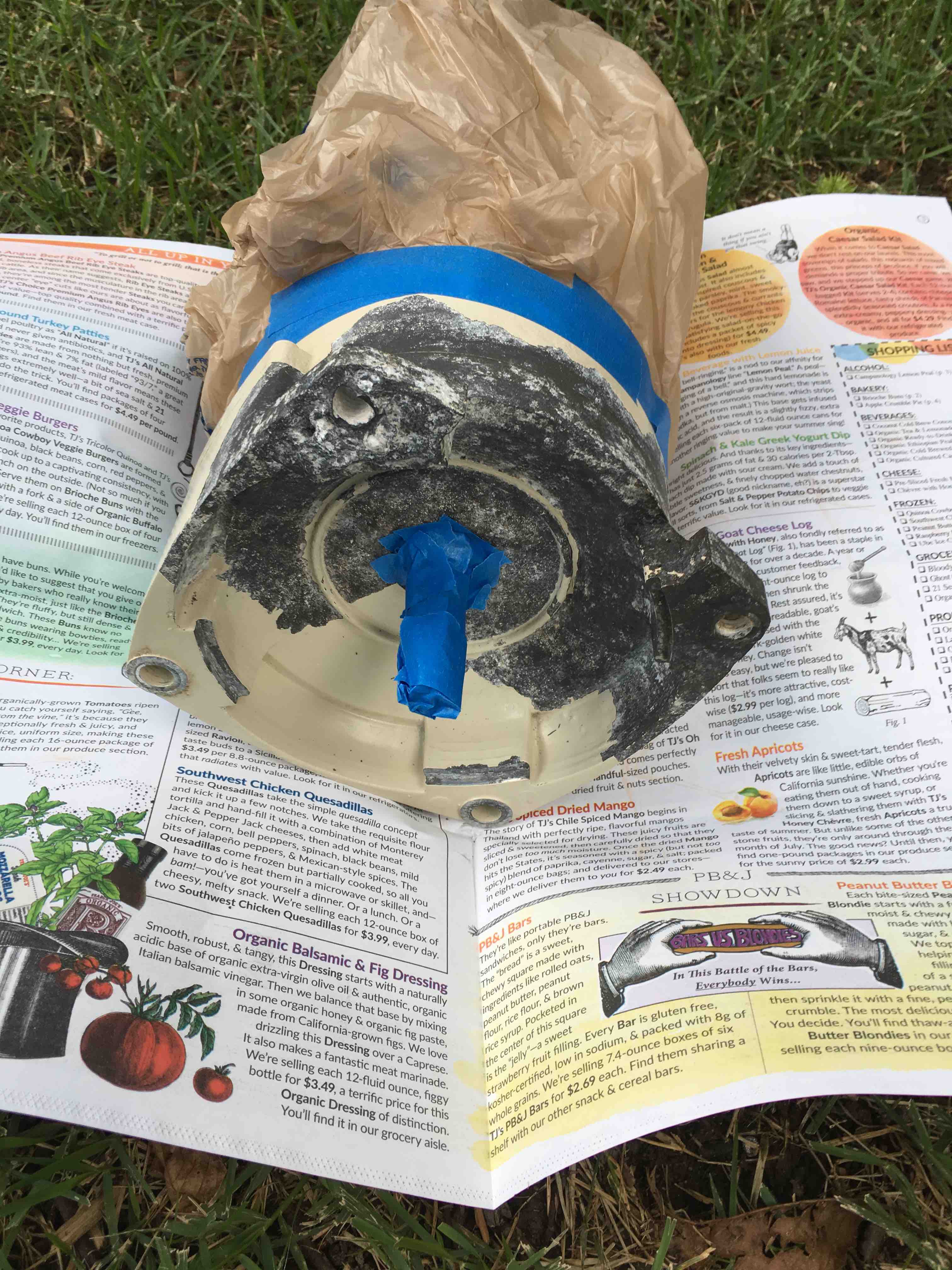

I started having a buzzing or vibration type noise over the weekend. Not high pitched. I disassembled the motor tonight expecting to find debris in the impeller but nothing. Then, when getting to the last step with the four bolts on the almond seal plate, after loosening the two upper bolts the plate came loose on its own.

The bottom two bolt receptacles had corroded and failed completely. Likely a result of my salt water over many years of having this pump. I suspect the noise was either due to that poor seal or connection, OR the enamel finish that is corroding off inside and flapping. The motor still runs, but given infiltration and failure of the enamel coating past that seal plate, I'm on the fence about whether to just replace the plate and bolts (cheap), or to replace the entire motor (expensive). I peeled off the failed enamel around the motor spindle area and it's fairly corroded in a manner similar to how an anode looks.

Just looking for some wisdom and/or opinions on what to do. I'm thinking replace the motor, but if they are robust and I get all new seals around it, maybe it keeps going.

Thanks

The bottom two bolt receptacles had corroded and failed completely. Likely a result of my salt water over many years of having this pump. I suspect the noise was either due to that poor seal or connection, OR the enamel finish that is corroding off inside and flapping. The motor still runs, but given infiltration and failure of the enamel coating past that seal plate, I'm on the fence about whether to just replace the plate and bolts (cheap), or to replace the entire motor (expensive). I peeled off the failed enamel around the motor spindle area and it's fairly corroded in a manner similar to how an anode looks.

Just looking for some wisdom and/or opinions on what to do. I'm thinking replace the motor, but if they are robust and I get all new seals around it, maybe it keeps going.

Thanks