What do you think of the Calimar pump? I see most say it is the same as the Circupool VS pump. How long have you had it? Figure for the price it may be worth a try. I can get an extra 3 years of warranty for $99, so for $719 I can get a 3HP VS pump with 4 years of warranty. Seems like a heck of a deal if it is reliable.I was at a pool this morning with a RJ60 controller. What a pleasure having the information at your fingertips.

New Pool Owner looking to upgrade some plumbing and equipment.

- Thread starter Hozzie

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Have it on a pool beginning of last season and it ran the lowest rpm the heater and SWCG allowed for the complete season without needing any attention. It is so quiet I had to physically check it out to see if it was running. I'm about to purchase another one for a pump change out.What do you think of the Calimar pump? I see most say it is the same as the Circupool VS pump. How long have you had it? Figure for the price it may be worth a try. I can get an extra 3 years of warranty for $99, so for $719 I can get a 3HP VS pump with 4 years of warranty. Seems like a heck of a deal if it is reliable.

What do you think of the Calimar pump? I see most say it is the same as the Circupool VS pump.

Calimar/Circupool/BD/Blue Torrent Pump - Further Reading

I'm sure that warranty through Pool Supply Unlimited is going to be much more reliable than the one that comes with purchase through CaliMar. There's reports of them being completely unresponsive to inquiries from customers (perks of buying generic).I can get an extra 3 years of warranty for $99, so for $719 I can get a 3HP VS pump with 4 years of warranty. Seems like a heck of a deal if it is reliable.

Last edited:

I went ahead and ordered the Calimar pump and extended warranty through PSU. My parents pool is the same size as yours so curious what RPM/Schedule/settings you are running your pool with your combination since we will have the same pump and SWG. Just looking for a decent starting point for when we get it filled back up with water after the liner is installed.Love mine as well! I'm only about a month into ownership, but so far so good.

I'm sure that warranty through Pool Supply Unlimited is going to be much more reliable than the one that comes with purchase through CaliMar. There's reports of them being completely unresponsive to inquiries from customers (perks of buying generic).

Hozzie, please look in my signature below for the link about filling the signature portion for yourself. We need that info to help you .......I went ahead and ordered the Calimar pump and extended warranty through PSU. My parents pool is the same size as yours so curious what RPM/Schedule/settings you are running your pool with your combination since we will have the same pump and SWG. Just looking for a decent starting point for when we get it filled back up with water after the liner is installed.

Done. Don't have too many details yet, but ordering things to be ready to replumb as soon as we can.Hozzie, please look in my signature below for the link about filling the signature portion for yourself. We need that info to help you .......

And just want to say Thank You! to all for the feedback. It is super helpful.

Last edited:

I'm currently running my pump 24/7 @ 1500 RPM along with my SWG which is set at 5% right now (solar cover is on, so I don't get much FC loss). I find that if I go any lower RPMs, then I get too much air accumulating in the pump basket as air leaks through the lid (common with VSPs at low speeds). With that said, this works for me, but might not be best for you. You're going to need to do some experimenting since every pool is unique. You might be able to go even lower on the RPMs (or higher) based many factors like your plumbing, distance from equipment pad to pool, weather conditions, etc.My parents pool is the same size as yours so curious what RPM/Schedule/settings you are running your pool with your combination since we will have the same pump and SWG. Just looking for a decent starting point for when we get it filled back up with water after the liner is installed.

Once you get everything installed and running without any leaks, then we can help you optimize it for your situation.

Highly recommend that you get a set of hi-temp unions as they don't come with the CaliMar pumps. The 3 HP version is sized for 2" fittings, so you'll need a reducer to go down to your 1.5" plumbing.

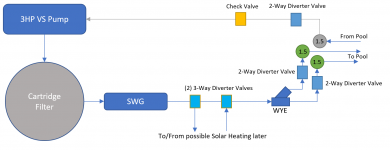

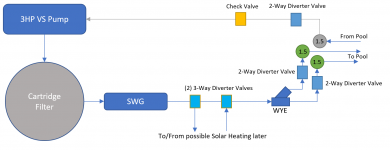

Hopefully last question for a bit. I plan to use good diverter valves when we replumb, not ball valves so I want to get them ordered. Just want to make sure I order everything I need. Here is what I have planned (excuse the PPT created layout, it was just easy).

I have three main questions.

1) Just want to confirm the check valve before the pump is correct and needed. It seems that way from what I have read, but want to make sure. I understand there needs to be a minimum distance from the pump (in my case let's call it 8").

2) I want to go ahead and pre-plumb in for solar heating if we decide to add that later. I just want to make sure it goes after the SWG and not before. And maybe I need to add a check valve after the SWG?

3) Is there something better than a WYE for splitting the line to the two return lines. I don't like T's as I would think that would add a lot of flow reduction/extra head to the system.

Thanks again.

I have three main questions.

1) Just want to confirm the check valve before the pump is correct and needed. It seems that way from what I have read, but want to make sure. I understand there needs to be a minimum distance from the pump (in my case let's call it 8").

2) I want to go ahead and pre-plumb in for solar heating if we decide to add that later. I just want to make sure it goes after the SWG and not before. And maybe I need to add a check valve after the SWG?

3) Is there something better than a WYE for splitting the line to the two return lines. I don't like T's as I would think that would add a lot of flow reduction/extra head to the system.

Thanks again.

Last edited:

Why are there 2 return lines to the pool? Do they go to different things, such as 1 are the standard returns in the pool and the other is a bubbler or something else? You could remove both those 2 way diverted valves and replace the WYE with a simple 3-way diverted valve. This would give you control over each pipe. The head loss on the 3-way valve is minimum. However, if you have the 2-way valves there to facilitate blowing out the lines then keep them and just put a TEE in place of the WYE.3) Is there something better than a WYE for splitting the line to the two return lines. I don't like T's as I would think that would add a lot of flow reduction/extra head to the system.

I would put the SWCG downstream of the solar by-pass. Also, the 3-way diverter valve on the exit side of the solar can be removed and replace with an TEE, then simply put a check valve up on the exit pipe. So you only have to turn one valve to divert flow to the solar.2) I want to go ahead and pre-plumb in for solar heating if we decide to add that later. I just want to make sure it goes after the SWG and not before. And maybe I need to add a check valve after the SWG?

You want a minimum of 10 inches of straight before the pump and that can include a check valve, the union, etc. Is the 2-way diverter valve there to facilitate blowing out the lines in winter?1) Just want to confirm the check valve before the pump is correct and needed. It seems that way from what I have read, but want to make sure. I understand there needs to be a minimum distance from the pump (in my case let's call it 8")

My recommendation is to use the Jandy or Pentair Never-Lube diverter valves as spare parts are readily available if and when you need them.

Not sure to be honest. I was able to get a picture from the seller of the house of the current plumbing. It has 1 inlet pipe and two outlet pipes in its current config (seems like a very basic configuration to me) as I show in the picture above. The lady has no idea about any of this. Her husband passed away and he took care of everything so she can't really answer much. My thought on the two diverter valves was simply to allow for flexibility in whatever maintenance would need to be done in the future, but a three way diverter makes sense too as I suspect I can have both lines open, either closed, or both closed via blocking the inlet so that should work and still give the same flexibility. I wasn't sure if the three ways essentially had 4 positions or if one line was always closed depending on the direction of the lever.Why are there 2 return lines to the pool? Do they go to different things, such as 1 are the standard returns in the pool and the other is a bubbler or something else? You could remove both those 2 way diverted valves and replace the WYE with a simple 3-way diverted valve. This would give you control over each pipe. The head loss on the 3-way valve is minimum. However, if you have the 2-way valves there to facilitate blowing out the lines then keep them and just put a TEE in place of the WYE.

Makes sense.I would put the SWCG downstream of the solar by-pass. Also, the 3-way diverter valve on the exit side of the solar can be removed and replace with an TEE, then simply put a check valve up on the exit pipe. So you only have to turn one valve to divert flow to the solar.

Diverter valve was just there to offer flexibility of maintenance. I don't know what I don't know, but for $40-$50 for a valve I would rather add it and have the option if I need/want it later.You want a minimum of 10 inches of straight before the pump and that can include a check valve, the union, etc. Is the 2-way diverter valve there to facilitate blowing out the lines in winter?

My recommendation is to use the Jandy or Pentair Never-Lube diverter valves as spare parts are readily available if and when you need them.

I was planning to get Jandy, but will look for the best deal for either brand.

The 3-way valve is designed to have both open or either one or the other. You can hack it to close off all flow but that is not recommended. Going with 2 of the 2-way valves is workable as well and will allow you to close off both lines, however just be careful not to do this with the pump running as you will dead head the pump. That is why a 3-way is designed not to close off all lines.have both lines open, either closed, or both closed via blocking the inlet so that should work and still give the same flexibility. I wasn't sure if the three ways essentially had 4 positions or if one line was always closed depending on the direction of the lever.

Thanks. I could always cut it off further upstream if needed. I would only do that if the pump was off for some type of maintenance and/or winterization.The 3-way valve is designed to have both open or either one or the other. You can hack it to close off all flow but that is not recommended. Going with 2 of the 2-way valves is workable as well and will allow you to close off both lines, however just be careful not to do this with the pump running as you will dead head the pump. That is why a 3-way is designed not to close off all lines.

What you can do if you use a 2-way valve, is to remove the handle after you install it and have it open. That little thumb screw on top can be unscrewed which allows the handle to be removed. Then put the thumb screw back on. This way, the valve cannot be turned accidentally by someone not understanding the purpose of the valve being there.Thanks. I could always cut it off further upstream if needed. I would only do that if the pump was off for some type of maintenance and/or winterization.

Didn't have the time to read through the last many threads from the diagram onwards but please buy no other then the jandy never lube. They're available in 2 way just open shut and three way aka diverter valve. Do it once do it right.

Hi All,

Coming back to this. My parents closed on the house and we are working to redo the equipment shed right now. Previously, the old pump was just 110v. We are running an additional 240v circuit for the new VS pump which will be on it's own GFCI circuit. I plan to just set the SWG to run off of 110v since it is already there and it also runs a light in the equipment shed so I don't want to (and don't have room in the conduit to run a second 240v circuit just for that). So the SWG and the Pump will be on separate circuits as recommended. I have read about the multiple options for this setup with pro's/con's. My plan is to run the pump 24/7 with a minimum RPM to keep the flow sensor active and then run at a higher RPM for a period of time for better skimming. I will probably do this higher rpm a couple of times a day. So I should be producing chlorine at all times and running the SWG at a lower setting.

I know the downside to this is if the pump stops and my only real safety is the flow control, but it seems this is probably a small risk. I don't want to get into a super complicated control board situation if not absolutely necessary as it doesn't appear there is a simple plug and play type option for this.

Am I missing anything on this? It seems this is a fairly acceptable way to run this setup now?

Coming back to this. My parents closed on the house and we are working to redo the equipment shed right now. Previously, the old pump was just 110v. We are running an additional 240v circuit for the new VS pump which will be on it's own GFCI circuit. I plan to just set the SWG to run off of 110v since it is already there and it also runs a light in the equipment shed so I don't want to (and don't have room in the conduit to run a second 240v circuit just for that). So the SWG and the Pump will be on separate circuits as recommended. I have read about the multiple options for this setup with pro's/con's. My plan is to run the pump 24/7 with a minimum RPM to keep the flow sensor active and then run at a higher RPM for a period of time for better skimming. I will probably do this higher rpm a couple of times a day. So I should be producing chlorine at all times and running the SWG at a lower setting.

I know the downside to this is if the pump stops and my only real safety is the flow control, but it seems this is probably a small risk. I don't want to get into a super complicated control board situation if not absolutely necessary as it doesn't appear there is a simple plug and play type option for this.

Am I missing anything on this? It seems this is a fairly acceptable way to run this setup now?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.