- Jul 21, 2013

- 65,173

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

@Jimrahbe @JamesW have you seen that Pentair has a new model MasterTemp heater according to the Installation manual Rev P 8/2020 currently on their website? It looks like Pentair again made significant changes to the model and kept the same name and SKU.

It looks like the manual has been significantly rewritten. And unfortunately the manual for the MasterTemp that most customers currently have is not on the MasterTemp page.

New manual is at https://www.pentair.com/content/dam...stertemp/Manual-MasterTemp-472592-English.pdf

Interesting changes seem to be....

It looks like the manual has been significantly rewritten. And unfortunately the manual for the MasterTemp that most customers currently have is not on the MasterTemp page.

New manual is at https://www.pentair.com/content/dam...stertemp/Manual-MasterTemp-472592-English.pdf

Interesting changes seem to be....

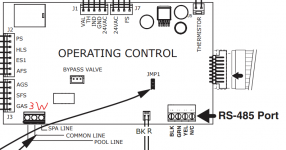

- Display is now 2 lines and shows error codes - page 46

- No SERVICE HEATER or SERVICE SYSTEM LED

- The diagnostic LEDs are not on the back of the board.

- Page 45 shows the Fenwal module and it is different with 5 possible error states instead of 3.