Update 2:

I finally connected with technical support at Fluidra / Jandy. Yes there is a factory default reset sequence for the Jandy TCX. And yes, this partially fixed my issues. More about the partially later.

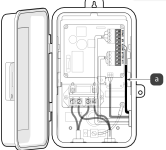

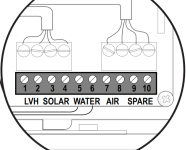

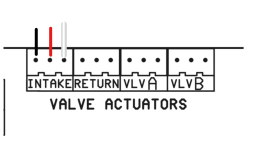

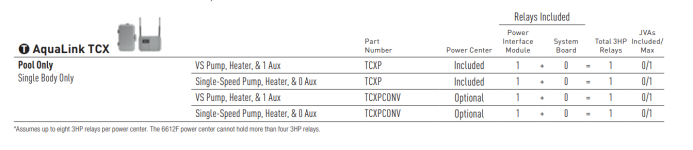

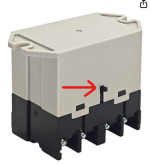

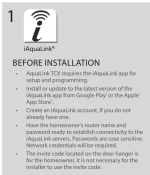

The Jandy TCX consists of the TCX PIB (Power Interface Board) which contains the relay, 2 RS-485 4 wire terminal blocks, and a plug in for a JVA. The second part of the TCX is the Command Hub which contains the Wi-Fi or wired ethernet, and bluetooth, connectivity plus three buttons for manual control of the TCX at the unit. All other control is done with the iAqualink mobile device app.

On the Command Hub is a button referred to as 'Service' (not labeled as such) which toggles between Auto, Quick Clean, Service, Time Out. The second button is to manually turn on/off the Pool Pump. The third button is for pairing a bluetooth device.

Now for the Reset to Factory Default sequence:

1. Power off the TCX, as a precaution wait 30 seconds.

2. Press and hold both the Service and Pool Pump buttons, while

3. Power on the TCX.

4. Look for the service lights to blink wildly.

5. I waited for 30 seconds after power on while still holding the 2 buttons (this part of the instructions was not clear, but worked for me. Then power off. Release buttons. (not sure you had to hold the buttons for the entire time after the blinking wildly, but this worked for me.

6. Wait 30 seconds after power off.

7. I did not always have a good reset so I adopted the following. Repeat steps 2-6 a second time.

8. Power up the TCX with no RS-485 devices connected except for the Command Hub. Power on for at least 30 seconds.

9. Power off the TCX.

10. Wait 30 seconds after power off.

11. Now proceed with connectivity of the TCX as provided in the Installation and Operations Manual.

12. Power off the TCX and wait 30 seconds after power off.

13. Connect any RS-485 connected devices. Beware that RS-485 devices will only register with the TCX when they are powered on either by the TCX relay or otherwise.

Good luck!

It appears that my brand new Century VGreen EVO VSP RS-485 communications may now be toast and I will be troubleshooting this. The salt water chlorine generator is communicating and can be controlled from iAqualink. The VSP pump is operating in standalone mode.