[/QUOTE]So, how much would you rather have the suction side come in on the end? Is it worth cutting, couplings and moving the risers over 8”? I mean it’s just plastic...but...ya know?

Also I have 3 surface returns....and 3 deep returns. Should I plumb the heater to just deliver through the 3 deep returns? Is that better for heat? Or better to spread among all 6?

I

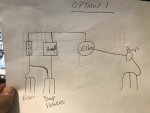

I drew up these options. One is more complicated I think. But Option 2 has a 4 way in it that may just naturally push more hot water through the deep returns on that side of the manifold...while still blending all 6 returns with the SWG...Option 3 feeds hot in one side, salt in another...maybe forcing more heat down the deep return side.

Thoughts? How the he’ll do I do this??

final phase here so I really appreciate all these small frequent answers...it’s really really helpful to have this support.

Last edited: