That standard does not actually set the velocities.Per PB: It is recommended by ANSI/APSP 7 Standards for Suction Entrapment Avoidance –that residential pools water velocity not exceed 8 ft per second.

It refers the issue to ANSI/APSP/ICC-5 2011, which does say 8 feet per second.

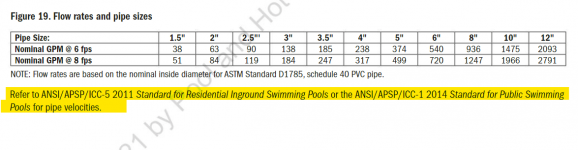

8 feet per second is 184 GPM in 3" pipe..

Assuming a total equivalent length of 120 feet, the velocity at 180 GPM is 7.95 feet per second and the head loss is 8.98 feet.

180 GPM should give you good action on the sheers and the infinity edge.

ANSI/PHTA/ICC-7 2020 American National Standard for Suction Entrapment Avoidance in Swimming Pools..

Published on Apr 19, 2021

The purpose of this standard is to establish anti-entrapment performance requirements for public and residential swimming pools, wading pools, field-constructed spas and hot tubs, and any other bather-accessible body of water, including but not limited to, catch pools, infinity edge basins, and water features that contain a skimmer, fully submerged Suction Outlet Fitting Assembly (SOFA) or vacuum port fitting.

ANSI/PHTA/ICC-7 2020 American National Standard for Suction Entrapment Avoidance in Swimming Pools..

The purpose of this standard is to establish anti-entrapment performance requirements for public and residential swimming pools, wading pools, field-constructed spas and hot tubs, and any other bather-accessible body of water, including but not limited to, catch pools, infinity edge basins, and...