Toxophilite

Silver Supporter

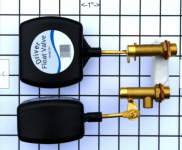

I had always read into your original post that your issue was a pressure leak at cracked thread boss. If so, just plug equalizer port and see if can overflows, making sure float valve is fully closing. If can is suspect leak, same as above suggests.