- Oct 1, 2022

- 764

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Just finished a bunch of projects on my pool

1) added Jandy valve between pump and filter

2) moved the flow switch

3) ascorbic acid treated pool

4) added an iphone app by Mark that controls the control board.

5) investigating cause of my dim pentair intellibright lights.

I was happy with all I did and all I learned from the members of this forum but 2 issues this morning appeared and I want to get them out of the way fast so I can enjoy my pools.

1) the pentair pump which is variable speed and is controlled by a Hayward Prologic lost its settings (probably from keeping it off x 4 days during ascorbic acid) and has 0 RPM when the controller turns it on but I can manually bring it to proper RPM

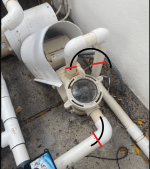

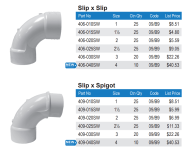

2) Where the PVC inserts into the top of pump there is a small leak. Nothing spraying just a wet surface. I know this needs to be fixed before it blows or something but it occurs to me that unless I do it with expertise I could crack the pump rim. Is this something I should tackle myself and if so very specific ideas would be welcomed? I was thinking of cutting the pipe and using a heat gun to remove old glue and pieces but I really don't know.

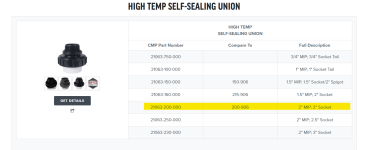

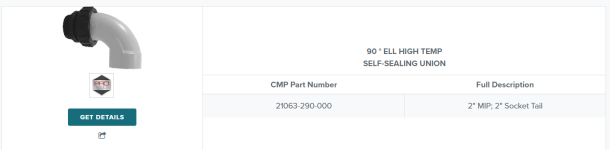

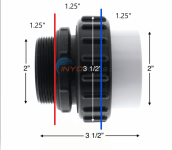

I wish it had a union connecting the pcv to pump and that is how I would like to go. Is there a name brand coupling that would be better than others?

addendum: is this what I need? https://www.amazon.com/Pentair-410028-IntelliFlo3-Variable-Models/dp/B0CNKTYXS7

1) added Jandy valve between pump and filter

2) moved the flow switch

3) ascorbic acid treated pool

4) added an iphone app by Mark that controls the control board.

5) investigating cause of my dim pentair intellibright lights.

I was happy with all I did and all I learned from the members of this forum but 2 issues this morning appeared and I want to get them out of the way fast so I can enjoy my pools.

1) the pentair pump which is variable speed and is controlled by a Hayward Prologic lost its settings (probably from keeping it off x 4 days during ascorbic acid) and has 0 RPM when the controller turns it on but I can manually bring it to proper RPM

2) Where the PVC inserts into the top of pump there is a small leak. Nothing spraying just a wet surface. I know this needs to be fixed before it blows or something but it occurs to me that unless I do it with expertise I could crack the pump rim. Is this something I should tackle myself and if so very specific ideas would be welcomed? I was thinking of cutting the pipe and using a heat gun to remove old glue and pieces but I really don't know.

I wish it had a union connecting the pcv to pump and that is how I would like to go. Is there a name brand coupling that would be better than others?

addendum: is this what I need? https://www.amazon.com/Pentair-410028-IntelliFlo3-Variable-Models/dp/B0CNKTYXS7

Attachments

Last edited: