Those with keen memories will recall that I have recently converted a Magiline pool to a traditional filtration system. Magiline is a proprietary pool system that uses a venturi effect to filter via cartridge filters.

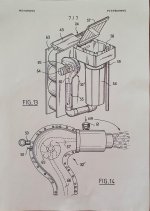

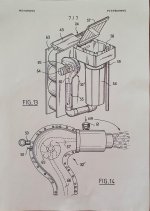

Since mid-season last year I have filtered the pool via a 63mm hose dropped into the pool basin. In March/April I dug out the skimmers and replumbed one so that it directly fed the pump. Below is the schematic of the skimmer/filter and so photos of the replumbing. just for context.

Life was good. Check valves not needed, suction was fine and the sight glass was full all the time. Happy days. The distance to the pump was about 2.5m head was about 30cm.

Last weekend I plumbed things in permanently. That included the previously existing 63mm suction pipe, the 63mm feed you see above and the same from the other end of the pool. I've also replumbed a line to a pre-existing line for the robot. Here's what it looks like

the near side is the same line that you saw in the first photo. There are three 90 degree angles added to the line. the total length of the pipe work is 5m. The vertical head remains the same at 30cm.

the near side is the same line that you saw in the first photo. There are three 90 degree angles added to the line. the total length of the pipe work is 5m. The vertical head remains the same at 30cm.

the middle feed is tapped off at the moment. that will go to the robot socket on the side of the pool. the secondary (vertical) point is to shut off the suction and enable a booster pump feed for a polaris 280. this, as said, is shut off. The intention is to be able to use the same plumbing both for a vacuum and a polaris 280.

The third feed is the other skimmer. Identical to the first above. The line is a continuous line of flexible 63mm all the way to the final riser into the pump. Total length is about 20m; 3 90 angles are in that circuit.

the feed at the top attaches to the existing (untouched) 63mm feed from the pool. The line to the original plumbing is about 150cm. Total length to the suction point is 17m. However the suction port is only 50mm even though the plumbing is 63mm. there is a reason for this (linked to the Magiline system).

there are no leaks on the flow side. beyond the odd drip from the waste pipe of the filter multi-port valve. I've put a shut off valve on that.

there are no leaks on the suction side that I have found. Done the foam test etc.

If I shut off all the valves apart from the known good line and start the pump I get almost no head. a week ago the suction was better than {insert whatever Jeremy Clarkson comment you can think of}

if I open all the valves then I get enough head to start the SWG but we're still only at the top of the inlet pipe. not the nice full pre-filter that I was getting 2 weeks ago. video of pre-filter (after 90 minutes of running the pump. Same this morning). Here is a video of the outflow where you can hear the cavitation. this is still going on today. Turning the multiport valve to waste I get slightly better but still no filling of the sight glass and still very slow to prime.

What have I done to deserve this from the Gods of swimming pools? The only aberrance I can think of is that there were a few days during which the pump and hydraulic circuit were free of water. Perhaps the seals in the pump have dried out? All the other seals (in the pipe unions) have been cleaned and newly greased.

Since mid-season last year I have filtered the pool via a 63mm hose dropped into the pool basin. In March/April I dug out the skimmers and replumbed one so that it directly fed the pump. Below is the schematic of the skimmer/filter and so photos of the replumbing. just for context.

Life was good. Check valves not needed, suction was fine and the sight glass was full all the time. Happy days. The distance to the pump was about 2.5m head was about 30cm.

Last weekend I plumbed things in permanently. That included the previously existing 63mm suction pipe, the 63mm feed you see above and the same from the other end of the pool. I've also replumbed a line to a pre-existing line for the robot. Here's what it looks like

the near side is the same line that you saw in the first photo. There are three 90 degree angles added to the line. the total length of the pipe work is 5m. The vertical head remains the same at 30cm.

the near side is the same line that you saw in the first photo. There are three 90 degree angles added to the line. the total length of the pipe work is 5m. The vertical head remains the same at 30cm. the middle feed is tapped off at the moment. that will go to the robot socket on the side of the pool. the secondary (vertical) point is to shut off the suction and enable a booster pump feed for a polaris 280. this, as said, is shut off. The intention is to be able to use the same plumbing both for a vacuum and a polaris 280.

The third feed is the other skimmer. Identical to the first above. The line is a continuous line of flexible 63mm all the way to the final riser into the pump. Total length is about 20m; 3 90 angles are in that circuit.

the feed at the top attaches to the existing (untouched) 63mm feed from the pool. The line to the original plumbing is about 150cm. Total length to the suction point is 17m. However the suction port is only 50mm even though the plumbing is 63mm. there is a reason for this (linked to the Magiline system).

there are no leaks on the flow side. beyond the odd drip from the waste pipe of the filter multi-port valve. I've put a shut off valve on that.

there are no leaks on the suction side that I have found. Done the foam test etc.

If I shut off all the valves apart from the known good line and start the pump I get almost no head. a week ago the suction was better than {insert whatever Jeremy Clarkson comment you can think of}

if I open all the valves then I get enough head to start the SWG but we're still only at the top of the inlet pipe. not the nice full pre-filter that I was getting 2 weeks ago. video of pre-filter (after 90 minutes of running the pump. Same this morning). Here is a video of the outflow where you can hear the cavitation. this is still going on today. Turning the multiport valve to waste I get slightly better but still no filling of the sight glass and still very slow to prime.

What have I done to deserve this from the Gods of swimming pools? The only aberrance I can think of is that there were a few days during which the pump and hydraulic circuit were free of water. Perhaps the seals in the pump have dried out? All the other seals (in the pipe unions) have been cleaned and newly greased.

Attachments

Last edited: