Hello All

Good Morning

I prepare some automation controllers on Arduino Board. so with the help of RS485 port, I am able to controller single Hayward VSP below is the packet to control Hayward VSP @ 100% speed and it working perfectly

ex. [ 0x10, 0x02, 0x0C, 0x01, 0x00, 0x64, 0x00, 0x83, 0x10, 0x03]

[START OF PACKET BYTES]: 2-bytes fix bytes which indicates Start of Packet [0x10 0x02]

[DESTINATION ADD] : 1- Byte Destination Address [0x0C]

[SOURCE ADD] : 1- Byte Source Address [0x01]

[FIX BYTE] : 1- Byte fix byte [0x00]

[DATA] : 1- byte Data - RPM Data in Parentage 0% - 100% [0x64]

[CHECKSUM] : 2 Byte Checksum [0x00 0x83]

[END OF PACKET BYTES]: 2-bytes fix bytes which indicates END of Packet [0x10 0x03]

---------------------------

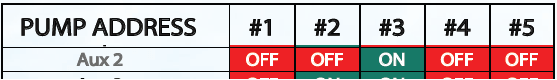

Now Problem is I want to control 3 Hayward Pump with the same Arduino Board, but as per RS485 protocol, all Hayward VSL should have different Slave addresses.

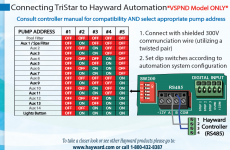

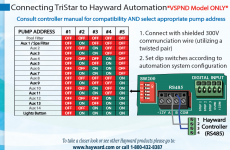

and I seen in Hayward VSP terminal side, it has the same DIP switch - and as per my study this DIP switch is used for setting the different Slave addresses (please check doc in the attachment )

so when I keep all DIP switch ALL OFF or only 2nd DIP switch ON -- so I am able to control VSP with 0x0C (12) slave address

But I was not able to find other slave addresses with respect to the DIP switch, anyone could we help me on this how-to identify Hayward VSP address and my understanding is correct or NOT ?

Thanks in advance

Good Morning

I prepare some automation controllers on Arduino Board. so with the help of RS485 port, I am able to controller single Hayward VSP below is the packet to control Hayward VSP @ 100% speed and it working perfectly

ex. [ 0x10, 0x02, 0x0C, 0x01, 0x00, 0x64, 0x00, 0x83, 0x10, 0x03]

[START OF PACKET BYTES]: 2-bytes fix bytes which indicates Start of Packet [0x10 0x02]

[DESTINATION ADD] : 1- Byte Destination Address [0x0C]

[SOURCE ADD] : 1- Byte Source Address [0x01]

[FIX BYTE] : 1- Byte fix byte [0x00]

[DATA] : 1- byte Data - RPM Data in Parentage 0% - 100% [0x64]

[CHECKSUM] : 2 Byte Checksum [0x00 0x83]

[END OF PACKET BYTES]: 2-bytes fix bytes which indicates END of Packet [0x10 0x03]

---------------------------

Now Problem is I want to control 3 Hayward Pump with the same Arduino Board, but as per RS485 protocol, all Hayward VSL should have different Slave addresses.

and I seen in Hayward VSP terminal side, it has the same DIP switch - and as per my study this DIP switch is used for setting the different Slave addresses (please check doc in the attachment )

so when I keep all DIP switch ALL OFF or only 2nd DIP switch ON -- so I am able to control VSP with 0x0C (12) slave address

But I was not able to find other slave addresses with respect to the DIP switch, anyone could we help me on this how-to identify Hayward VSP address and my understanding is correct or NOT ?

Thanks in advance