Firstly, thanks for a great community! I have never owned a pool but have been researching for some weeks so excuse me if I come across as ignorant. We are working with a local mennonite pool builder in Mexico but he actually produces fiberglass pools to sell in the USA more than installs them here. We're pushing the limits of his and our own knowledge so I'd like to ask this community on their thoughts.

We are hoping to install a large spa pool for hydrotherapy (10' x 20' x 4.5' fiberglass) which has 14 "seats" that we want to install a mix of venturi and bubbler jets. These pumps will operate on a timer that will turn on the jets for 15 minutes at a time. This requirement as well as our location and the local availability of what manufacturers would consider professionals to install (there are none) mean the usual choices might not be the best recommendation.

For the circulation system I'm looking to install the following in a mechanical room around 30-40 feet away:

RAYPAK ELS-R-0030-3-TI

CircuPool® RJ-20 Salt Chlorine Generator OR EDGE15

CircuPool CC150 Cartridge Filter

CircuPool SmartFlo® Variable Speed Pool Pump - 1.7 THP

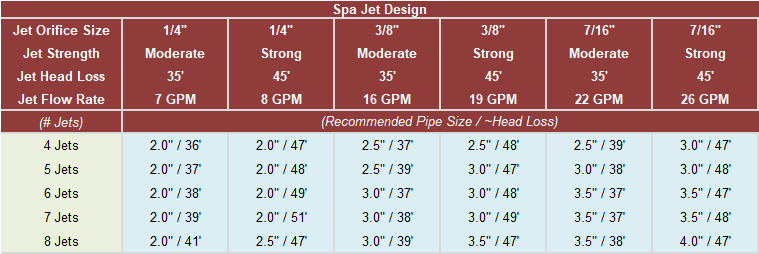

However for the jet system I was considering using spa pumps which can be installed closer and below water level such as a 5HP Waterway Viper Spa Pump 2 Spd, 2.5" In-Out or another single speed version. It would be signficantly more cost effective when running between 50-100 spa jets and we would only ever need to run at a single speed for short periods of time when it is turned on. We won't get the better warranty length of a pool pump due to the lack of technicians and I'm unsure if the 15 minute off and on cycles would be suitable for these pumps as well.

While my suggestion is definitely not the norm does it seem reasonable to explore this path further?

We are hoping to install a large spa pool for hydrotherapy (10' x 20' x 4.5' fiberglass) which has 14 "seats" that we want to install a mix of venturi and bubbler jets. These pumps will operate on a timer that will turn on the jets for 15 minutes at a time. This requirement as well as our location and the local availability of what manufacturers would consider professionals to install (there are none) mean the usual choices might not be the best recommendation.

For the circulation system I'm looking to install the following in a mechanical room around 30-40 feet away:

RAYPAK ELS-R-0030-3-TI

CircuPool® RJ-20 Salt Chlorine Generator OR EDGE15

CircuPool CC150 Cartridge Filter

CircuPool SmartFlo® Variable Speed Pool Pump - 1.7 THP

However for the jet system I was considering using spa pumps which can be installed closer and below water level such as a 5HP Waterway Viper Spa Pump 2 Spd, 2.5" In-Out or another single speed version. It would be signficantly more cost effective when running between 50-100 spa jets and we would only ever need to run at a single speed for short periods of time when it is turned on. We won't get the better warranty length of a pool pump due to the lack of technicians and I'm unsure if the 15 minute off and on cycles would be suitable for these pumps as well.

While my suggestion is definitely not the norm does it seem reasonable to explore this path further?