Hi - I've got a Pentair EasyTouch panel. I just self-installed a rooftop solar heating panel array. I have a 3-way Jandy valve to handle panel on-off flow.

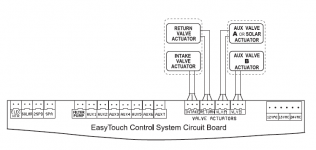

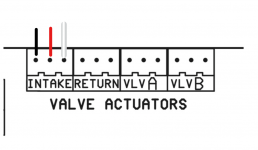

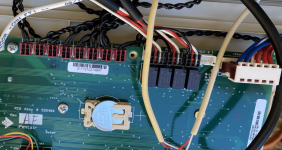

I have a 24 VAC Goldline valve actuator from another project. I assumed the Easytouch built-in solar valve controller would send the necessary control signals for the Goldline (24 VAC switched on 3 wires), but when I inspected the EasyTouch system, I see that there's a small relay that clicks when solar is enabled/disabled but there's no voltage on the any of the 3 EasyTouch solar connector pins (Valve A). And the pins seem a bit small to handle the AC current that an actuator would require, but I might be wrong on that...

So how does a Pentair actuator valve connect to the EasyTouch panel? Does it derive 24 VAC elsewhere and just use the relay as a signal to operate the valve? I know electronics well enough to use the relay as a controller for some external circuitry I'd have to build for the Goldline actuator, but I was hoping the Pentair would provide the simple switched AC necessary, rather than me having to add additional circuitry.

I can't find a schematic for the actual operation of the EasyTouch-to-Pentair actuator circuit...can anybody advise how the EasyTouch does it with a Pentair actuator and suggest a means to do that with a third-party actuator (my Goldline)?

Thanks...

I have a 24 VAC Goldline valve actuator from another project. I assumed the Easytouch built-in solar valve controller would send the necessary control signals for the Goldline (24 VAC switched on 3 wires), but when I inspected the EasyTouch system, I see that there's a small relay that clicks when solar is enabled/disabled but there's no voltage on the any of the 3 EasyTouch solar connector pins (Valve A). And the pins seem a bit small to handle the AC current that an actuator would require, but I might be wrong on that...

So how does a Pentair actuator valve connect to the EasyTouch panel? Does it derive 24 VAC elsewhere and just use the relay as a signal to operate the valve? I know electronics well enough to use the relay as a controller for some external circuitry I'd have to build for the Goldline actuator, but I was hoping the Pentair would provide the simple switched AC necessary, rather than me having to add additional circuitry.

I can't find a schematic for the actual operation of the EasyTouch-to-Pentair actuator circuit...can anybody advise how the EasyTouch does it with a Pentair actuator and suggest a means to do that with a third-party actuator (my Goldline)?

Thanks...

Last edited: