Hi Guys!

I'm trying to avoid the cost of buying the Aquarite Controller box to power my T-15 Cell.

I read in another thread that you can power the Pentair IC40 using a 36v 10a power supply and I want to do the same. I'm just not what voltage to power the T-15 cell with.

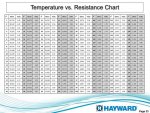

According to inyopools.com (http://www.inyopools.com/HowToPage/h...-values.aspx):

"...CELL VOLTAGE - The Cell Voltage is typically 22.0 to 25.0 Volts when chlorine is being generated, otherwise it is 30 to 35 Volts."

and

"...CELL AMPERAGE - The cell's average amperage when chlorine is being generated varies with the size of cell installed: T-15 is 3.1 to 8.0 amps; T-9 is 2.3 to 6.7 amps; T-5 is 1.9 to 5.7 amps; and t-3 is 1.3 to 4.5 amps. When the cell is not generating chlorine the amperage is 0"

I do realize that without a controller, the salt cell will always be generating but I intend to use a different controller (Arduino controller) with a relay to handle the powering on/off of the salt cell.

My question is what power supply should do the trick? The same as the one you guys mentioned for the Pentair IC40?

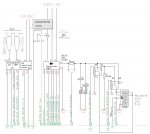

I believe that the Aquarite T-15 Cell has 5 connections in the cable that runs to the controller. Does anybody know which pins are for what?

I really do appreciate any direction you could give me on this. Thanks!

I'm trying to avoid the cost of buying the Aquarite Controller box to power my T-15 Cell.

I read in another thread that you can power the Pentair IC40 using a 36v 10a power supply and I want to do the same. I'm just not what voltage to power the T-15 cell with.

According to inyopools.com (http://www.inyopools.com/HowToPage/h...-values.aspx):

"...CELL VOLTAGE - The Cell Voltage is typically 22.0 to 25.0 Volts when chlorine is being generated, otherwise it is 30 to 35 Volts."

and

"...CELL AMPERAGE - The cell's average amperage when chlorine is being generated varies with the size of cell installed: T-15 is 3.1 to 8.0 amps; T-9 is 2.3 to 6.7 amps; T-5 is 1.9 to 5.7 amps; and t-3 is 1.3 to 4.5 amps. When the cell is not generating chlorine the amperage is 0"

I do realize that without a controller, the salt cell will always be generating but I intend to use a different controller (Arduino controller) with a relay to handle the powering on/off of the salt cell.

My question is what power supply should do the trick? The same as the one you guys mentioned for the Pentair IC40?

I believe that the Aquarite T-15 Cell has 5 connections in the cable that runs to the controller. Does anybody know which pins are for what?

I really do appreciate any direction you could give me on this. Thanks!