- Aug 3, 2013

- 25

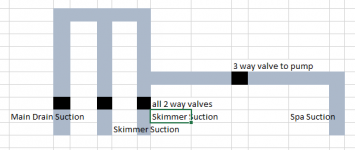

My valve body cracked and I am not sure of the best way to go about replumbing this. The valve in question is the one right behind the new one in this photo. The hose coming out of that pipe and heading to the right is for a 'HASA Liquidator"

My concern is that there is simply not a good way to do this and be able to fit all of the pieces back together. Do I simply need to use a union or unions strategically?

What would you recommend?

Thank you!

My concern is that there is simply not a good way to do this and be able to fit all of the pieces back together. Do I simply need to use a union or unions strategically?

What would you recommend?

Thank you!