So we just got a hot tub in December of 2021. Over the past year, I’ve learned a lot about hot tub water chemistry and have gotten really good at it. We bought a saltron mini and have used it for a year. Everything seemed great! Then last week, the breaker kept tripping and we couldn’t figure out what was wrong. My husband replaced the breaker and it still kept tripping. Finally had the repairman come out today and it turns out the heater is corroded from using the salt cell. I have always kept the salt in check, way below 3000 ppm. I am so bummed about this. According to the repairman, there is not an inline salt system available for our hot tub. I am so bummed because the saltron mini meant we could go on vacations, etc without anyone having to babysit the chlorine levels. Anyone have a similar experience and found a solution?

Hot tub heater corrosion

- Thread starter AlexiaM

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 23, 2015

- 25,794

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The original heater may have been cheap Teflon coated steel or Incoloy. Neither are very good for long term corrosion resistance. If you can replace the heater with a titanium heater element, it will last A LOT longer.

Also, if you are using dry acid (sodium bisulfate) for pH control, then the excess sulfate added to the tub water will cause more advanced corrosion to occur. You want to strictly use muriatic acid for pH control.

Also, if you are using dry acid (sodium bisulfate) for pH control, then the excess sulfate added to the tub water will cause more advanced corrosion to occur. You want to strictly use muriatic acid for pH control.

Methuselah

Well-known member

Depending on how handy you are the element can be replaced, the tube with element, or the entire pack... chances are you can pay someone for either of the first two choices cheaper than doing the third yourself (and maybe get a warranty of some kind in the process? ).

I only use muriatic acid. I don’t have a photo of the heater but the repairman is charging us about $550 for both a replacement heater and labor. I don’t know any other way to keep my chlorine up when I’m away so I’m really bummed to miss out on using my saltron. My husband is a contractor and super handy. Can anyone direct me to a website that would allow us to replace parts in the new heater that will make it corrosion resistant?

I don't agree that the salt system caused the heater failure.

Many tubs have salt with no problems.

Many times scale will form due to excessive temperature and excessive CSI and scale will create an insulating layer on the element that will cause the element to overheat and break open.

Maybe the heater was cheap, maybe the chemistry was bad or maybe the heater dry fired.

Many tubs have salt with no problems.

Many times scale will form due to excessive temperature and excessive CSI and scale will create an insulating layer on the element that will cause the element to overheat and break open.

Maybe the heater was cheap, maybe the chemistry was bad or maybe the heater dry fired.

- May 23, 2015

- 25,794

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The repairman should be able to tell you what parts they ordered and if the heater element is titanium or not.

I also agree with @JamesW that you shouldn’t abandon the Saltron just because someone said “corrosion”. It’s easy to blame “salt” because everyone thinks of cars near the ocean that rust through from salt spray. The reality is, 3000ppm salinity is 10% of the salinity of seawater and about half the salinity of the tears in your eyes. Most people can barely taste the salt in an SWG pool or tub and it’s not going to cause corrosion in and of itself. Typically it’s low pH that drives corrosion or, as James alluded to, water that is hard with minerals and the scale that builds up on the heater element leads to its death.

Also, how regularly are you changing the water in the tub? I am always an advocate of frequent water exchanges (every 2-3 months) so as to avoid the many water chemistry issues that come up with trying to hold on to old water.

I also agree with @JamesW that you shouldn’t abandon the Saltron just because someone said “corrosion”. It’s easy to blame “salt” because everyone thinks of cars near the ocean that rust through from salt spray. The reality is, 3000ppm salinity is 10% of the salinity of seawater and about half the salinity of the tears in your eyes. Most people can barely taste the salt in an SWG pool or tub and it’s not going to cause corrosion in and of itself. Typically it’s low pH that drives corrosion or, as James alluded to, water that is hard with minerals and the scale that builds up on the heater element leads to its death.

Also, how regularly are you changing the water in the tub? I am always an advocate of frequent water exchanges (every 2-3 months) so as to avoid the many water chemistry issues that come up with trying to hold on to old water.

I purchased a brand new hot tub and started using the SmarterSpa salt water chlorinator. After 8 months the heater coil went. It was replaced under warranty. Now after 6 months the replaced heater coil has failed again… the water chemistry is balanced exactly to the recommended settings, so I’m suspecting the heater coil doesn’t like the salt water… I think it was around 1500ppm…

If I can’t get this replaced under warranty then I’ll get a titanium heater and if that goes then I may have to revert back to bromine as much as I hate to…

If I can’t get this replaced under warranty then I’ll get a titanium heater and if that goes then I may have to revert back to bromine as much as I hate to…

$550 is really pricey if he's just replacing your element.I only use muriatic acid. I don’t have a photo of the heater but the repairman is charging us about $550 for both a replacement heater and labor. I don’t know any other way to keep my chlorine up when I’m away so I’m really bummed to miss out on using my saltron. My husband is a contractor and super handy. Can anyone direct me to a website that would allow us to replace parts in the new heater that will make it corrosion resistant?

Still overpriced if it's the heater assembly.

Great deal if it's the whole spa pack.

Which is it?

I can't easily find the manufacturer of the pack inside your spa. As others have requested, a picture of the equipment bay will help us help you.

RDspaguy

In The Industry

Was it new when you got it in Dec '21?

Is the tech from the dealer you purchased it from?

If so, they denied your warranty claim (for the corrosion and swg) and now have to replace it with OEM parts, which may be all a dealer carries. The OEM (spa manufacturer) does not buy elements, therefore does not replace elements or sell them. This does not mean there is no element, it just means you can't get it from them. Post a pic of the heater element, or at least the heater tube and control box, so we know what you've got.

Is the tech from the dealer you purchased it from?

If so, they denied your warranty claim (for the corrosion and swg) and now have to replace it with OEM parts, which may be all a dealer carries. The OEM (spa manufacturer) does not buy elements, therefore does not replace elements or sell them. This does not mean there is no element, it just means you can't get it from them. Post a pic of the heater element, or at least the heater tube and control box, so we know what you've got.

- May 23, 2015

- 25,794

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Well, it looks like you're just stuck with them replacing the corroded heater with the same exact model. The only way to go to titanium would be to replace the internal heating element inside that tube but that is custom work that your spa shop is probably not going to do. They can remove and replace OEM parts with OEM parts and get covered under warranty with the manufacturer. But the minute you disassemble the internals of the heater, you own all the liability for it.

You can stop using the Saltron and not add salt to see if this new heater lasts longer than your old heater did. But if it corrodes again within a year, then there's something else causing it.

You can stop using the Saltron and not add salt to see if this new heater lasts longer than your old heater did. But if it corrodes again within a year, then there's something else causing it.

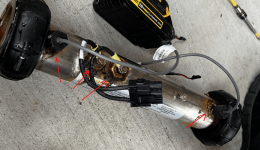

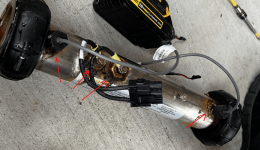

That's the most corrosion I have ever seen, so I don't blame them, for blaming the salt. I believe you do have a large conductivity issue. High TDS can elevate that, which salt will contribute to.Ok so here it is. They are here right now replacing it. Total cost of parts and labor are included in the $550 price. What do you all think as far as cause? They say it’s the salt in the water. Just want some feedback as I really love the convenience of the Saltron but might have to give it up.View attachment 474477

But I would not have charged you nearly that much for the repair. If you did the drain and refill, I'd have invoiced for an hour of labor at most, at $75. The part is roughly $150.

If they sat and waited for the 2 hours to drain and refill, then it's less absurd from an hourly standpoint, but I'd argue they're taking advantage of that in their favor. Not my style.

Last edited:

RDspaguy

In The Industry

That is a Balboa heater assembly, and you can most definitely get a titanium element for it.

Alot of dealers only service what they sell and only get parts from the oem. As I said, the oem usually doesn't buy elements, list them as a part number, or have them to sell.

As for cause, you'll hear alot of theories. The salt level in the spa is roughly 10% of ocean water, and in theory should not be of a sufficient concentration to cause the damage that, in my experience and the opinion of most spa manufacturers, they do in fact cause. I am no chemist, so couldn't say for sure myself, but I'm inclined to say that, like any dissolved solid, salt will come out of solution at high ph/alk. And, like other dissolved solids, heat can act as a catalyst for this reaction, causing a layer of salty calcium scale to form on the heater.

Another possibility is voltage leaking from the salt cell (which functions by running electric current through the water inside the cell) and finding ground at the heater.

Alot of dealers only service what they sell and only get parts from the oem. As I said, the oem usually doesn't buy elements, list them as a part number, or have them to sell.

As for cause, you'll hear alot of theories. The salt level in the spa is roughly 10% of ocean water, and in theory should not be of a sufficient concentration to cause the damage that, in my experience and the opinion of most spa manufacturers, they do in fact cause. I am no chemist, so couldn't say for sure myself, but I'm inclined to say that, like any dissolved solid, salt will come out of solution at high ph/alk. And, like other dissolved solids, heat can act as a catalyst for this reaction, causing a layer of salty calcium scale to form on the heater.

Another possibility is voltage leaking from the salt cell (which functions by running electric current through the water inside the cell) and finding ground at the heater.

+1. Arctic spas with their onzen salt systems are the most corroded elements we've ever changed. But still didn’t quite match the OPs example.The salt level in the spa is roughly 10% of ocean water, and in theory should not be of a sufficient concentration to cause the damage that, in my experience and the opinion of most spa manufacturers, they do in fact cause.

I'm front seat with you on this. That is aggressive corrosion, and I'd bet it's related to conductivity.Another possibility is voltage leaking from the salt cell (which functions by running electric current through the water inside the cell) and finding ground at the heater.

- May 23, 2015

- 25,794

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Another possibility is voltage leaking from the salt cell (which functions by running electric current through the water inside the cell) and finding ground at the heater.

I'm front seat with you on this. That is aggressive corrosion, and I'd bet it's related to conductivity.

I do have a lot of experience in electrochemistry and it is a very good possibility but it's also a very complex one too. TDS (conductivity) and small stray currents could easily drive a corrosion process. One also has to look at the materials as well. The heater element is likely Incoloy which is "ok" in a chloride rich environment BUT if it is in contact with any dissimilar metals that are more noble than it, then corrosion can happen from galvanic effects as well. My guess is that the standoffs used between the heater element and the tube are probably not great and there is likely a sufficient enough humidity inside the cabinet to allow moisture to accumulate there. This will then create a pathway for stray currents to flow to ground that is good enough to start corrosion but not enough to trip any GFI's. Looking at the heater tube I can say those connections are pretty exposed and open. I would suggest that a small dollop of high temperature RTV sealant OR using a dielectric grease on the contacts would help to mitigate any stray currents.

RDspaguy

In The Industry

Purchased through a supplier. Purchased from the spa manufacturer, it's going to be quite a bit more, as they mark it up and so does the dealer.part is roughly $150.

Draining takes maybe 15 minutes, it's filling that takes the time. If you want me to warranty the repair then I must test it. If you fill and it leaks or something, I charge to come back out. That's the option given to my customers. I do not see it as taking advantage of anything. I stay to ensure it works, and charge for my time, or you roll the dice on doing it yourself. You could fill wrong, get an airlock, and burn up that brand new heater. I will not cover it. If you take it upon yourself to do my job don't expect me to warranty it. And I'll put that on your paperwork and you'll sign it.they sat and waited for the 2 hours to drain, then it's less absurd from an hourly standpoint, but I'd argue they're taking advantage of that in their favor.

And I haven't charged $75 an hour in a decade. Service charge and one hour minimum puts you at $200 to get me in your driveway, and I'm one of the cheaper guys in town.

That said, I'd have put an element in it and likely not had to drain it to do so. So my bill would have been significantly lower as well, but not because I left you to do my job.

RDspaguy

In The Industry

Does this increase with acidic water?contact with any dissimilar metals that are more noble than it, then corrosion can happen from galvanic effects as well.

What standoffs? The heater surface is grounded at the mounting bolts, the element is isolated within a (ceramic?) coating and protrudes from the ends where the terminals are welded on. The whole mess is sealed with epoxy beneath the terminal.standoffs

This is, quite literally, the standard for spa heaters. They are nearly all like this, and have been for decades. If the heater design were at fault, it would be a universal problem. This is not to say that they do not short out at this location, usually from a leak/seep at the epoxy seal. The same epoxy seal that can be damaged during installation if you don't hold the bottom bolt head on the terminal while tightening the nut.Looking at the heater tube I can say those connections are pretty exposed and open.

All 4 holes show corrosion, which points to heat induced steel damage during the cutting process maybe from a bad drill bit.

The same thing happens on the stainless steel band in a Pentair filter.

In any case, we need to see the actual element.

Remove the two nuts and pull out the element.

The service tech should have pulled the element for examination before making a diagnosis about the cause of the element failure.

The same thing happens on the stainless steel band in a Pentair filter.

In any case, we need to see the actual element.

Remove the two nuts and pull out the element.

The service tech should have pulled the element for examination before making a diagnosis about the cause of the element failure.

Last edited:

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.