My pool/spa is 21 years old with an A&A in-floor cleaning system. I have often had issues with the pop-ups not fully popping-up. I replaced all popups after four or five years (which helped greatly). I am replaced two last July and will replace many of the others in the next month.

My Sta-Rite cartridge filter (with new filters) registers 25-30psi (depending on zone), the popups registering only 6-7psi. I cleared all the popups and skimmer lines last summer after I found bits of CPVC causing blockages. (The CPVC pieces came from a recent heater replacement installation.) I also manipulated the inflow and outflow valves in many combinations in order to find the greatest psi at the pop-ups. A&A states 10psi at the pop-up is desirable.

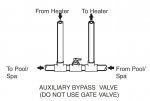

While my warranty with A&A is excellent, getting detailed information regarding the operation of their systems is severely lacking. My question - Would having a heater bypass added to my plumbing increase the psi at the pop-ups? Note: this is a Raypak heater, not solar, not a heat pump. (I do have a slight leakage at the actuator and will have it replaced when I have the pool replastered in the coming months.)

My Sta-Rite cartridge filter (with new filters) registers 25-30psi (depending on zone), the popups registering only 6-7psi. I cleared all the popups and skimmer lines last summer after I found bits of CPVC causing blockages. (The CPVC pieces came from a recent heater replacement installation.) I also manipulated the inflow and outflow valves in many combinations in order to find the greatest psi at the pop-ups. A&A states 10psi at the pop-up is desirable.

While my warranty with A&A is excellent, getting detailed information regarding the operation of their systems is severely lacking. My question - Would having a heater bypass added to my plumbing increase the psi at the pop-ups? Note: this is a Raypak heater, not solar, not a heat pump. (I do have a slight leakage at the actuator and will have it replaced when I have the pool replastered in the coming months.)