Edit: repair and initial threads merged, scroll down for the repair

Hi all,

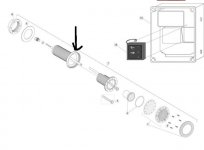

pool is thawed and to my dismay both of my PAL Lighting LED lights have had the front of the pool niches break off flush with the pool. The niches seem to still be sealed around the fiberglass with silicone and don’t appear to be leaking.

The lights tread into the niche so i could still technically screw in both lights. The problem is that there is now nothing holding the lights back from being pushed out the back of the fiberglass. To screw in the lights I need to apply a good amount of pressure, which I think may break the silicone holding the lights there.

Every winter I winterize the same way by letting the lights hang. This year they both broke. Clearly the water froze and then moved vertically thus breaking anything in the way.

Any techniques to fix this without digging outside the pool?

Hi all,

pool is thawed and to my dismay both of my PAL Lighting LED lights have had the front of the pool niches break off flush with the pool. The niches seem to still be sealed around the fiberglass with silicone and don’t appear to be leaking.

The lights tread into the niche so i could still technically screw in both lights. The problem is that there is now nothing holding the lights back from being pushed out the back of the fiberglass. To screw in the lights I need to apply a good amount of pressure, which I think may break the silicone holding the lights there.

Every winter I winterize the same way by letting the lights hang. This year they both broke. Clearly the water froze and then moved vertically thus breaking anything in the way.

Any techniques to fix this without digging outside the pool?

Last edited: