- Sep 15, 2021

- 117

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

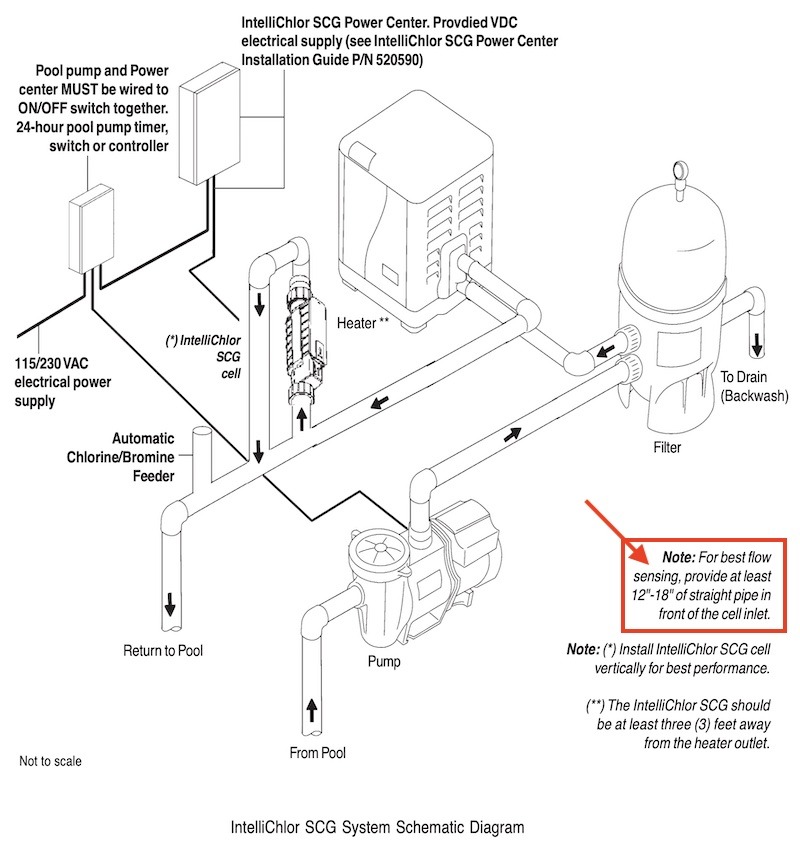

- SWG Type

- Pentair Intellichlor IC-40

I’m constructing a new pool. It has spa, one bubbler, 2 sheer descents and a slide. I would like know what is best way to operate them independently and together if required. I got four actuators for this setup. Appreciate any thoughts on this setup.