I'm in a process of changing the Vari-Flow valve that cracked. I think If I turn my sand filter 90 degrees I will be able to get rid of 2 close 90 degrees on the inlet side and one 90 degrees turn on the outlet side. Is it worth the effort?

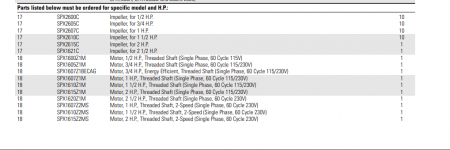

This is inground 20 by 40 pool, the pump is 1 1/2 hp, 1 1/2 PVC plumbing.

This is inground 20 by 40 pool, the pump is 1 1/2 hp, 1 1/2 PVC plumbing.