Hey y'all! I just installed a solar heater pad but it's 70ft (23m) away (one way, not including the return back down) and has to climb a slope of 35 degrees, there's barely any water pressure.

My pump (3 hp) has to run at 2250 rpm just to move the water round trip.

My pool vac (suction side) barely moves.

I can't crank up the rpm (nor do I really want to) because the system pressure is about 12 PSI and the heaters are only rated for 10 PSI.

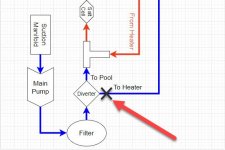

Post filter, I have a diverter to adjust how much water goes to the heater vs directly to the pool. The info above refers to 100% of the water going through the heater.

I'm trying to think of how I could make this work. Thinking a booster pump might solve the issue, but unsure of a couple of things:

I would love to get your thoughts folks, thanks for reading!

My pump (3 hp) has to run at 2250 rpm just to move the water round trip.

My pool vac (suction side) barely moves.

I can't crank up the rpm (nor do I really want to) because the system pressure is about 12 PSI and the heaters are only rated for 10 PSI.

Post filter, I have a diverter to adjust how much water goes to the heater vs directly to the pool. The info above refers to 100% of the water going through the heater.

I'm trying to think of how I could make this work. Thinking a booster pump might solve the issue, but unsure of a couple of things:

- Would a booster pump increase the overall system pressure? If so, significantly?

- Where should it be placed? On the way up to the heater or on the way back down? Somewhere else?

I would love to get your thoughts folks, thanks for reading!