We are in the process of replacing a leaking 3-way Pentair Valve after a couple years of replacing diverter & O-rings. Just tired of trying to fix going the "parts" route. In doing so, we have to cut PVC that includes an "inline" check valve that feeds into the Filter. I read on InyoPools.com that there are 2 strengths of springs - 1/2 lb & 2 lb. .. I just want to confirm that is true .. that since we Solar Water on the roof, this requires the higher tension spring. TIA

Check Valve - 1/2 lb or 2 lb for Solar ?

- Thread starter cody21

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 54,108

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I have solar on a single story roof. I use Jandy check valves, with the clear covers, not the sealed up cheaper PVC type. My system works as intended. One of my Jandy check valves was converted to a FlowVis flow meter, so I can monitor the flow rate through my solar panels, which assures me I'm running them as cost-effectively as possible, and getting the best heat-to-cost ratio possible. That one has paid for itself. That's all I know... In all my research about installing my solar system, I never came across a mention of check valve spring tension.

I have one check valve on the return pipe that comes down from the panels. That one keeps water from back-flowing through the panels when solar is not called for and the pump is running. I have a second one (the FlowVis, which is also a check valve) that sits between my pump and filter, and that keeps water from the draining panels from back-flowing through the filter (when the pump is off). That check valve can also be located between the filter and the three-way solar valve, it'll do the same job in either location.

These are what work for me:

If the FlowVis sounds interesting, but not in the budget, a Jandy check valve can later be upgraded to a FlowVis flow meter, as they come with and without the body (different price points). If your pump is single speed, monitoring flow might not be all that valuable for now. But when that pump dies, and is replaced with a variable speed pump, a FlowVis would be handy to fine-tune your solar panels. You'd have the option of upgrading your Jandy check valve to a FlowVis if you wanted to. Which is a potential additional reason to go with Jandy now.

I have one check valve on the return pipe that comes down from the panels. That one keeps water from back-flowing through the panels when solar is not called for and the pump is running. I have a second one (the FlowVis, which is also a check valve) that sits between my pump and filter, and that keeps water from the draining panels from back-flowing through the filter (when the pump is off). That check valve can also be located between the filter and the three-way solar valve, it'll do the same job in either location.

These are what work for me:

If the FlowVis sounds interesting, but not in the budget, a Jandy check valve can later be upgraded to a FlowVis flow meter, as they come with and without the body (different price points). If your pump is single speed, monitoring flow might not be all that valuable for now. But when that pump dies, and is replaced with a variable speed pump, a FlowVis would be handy to fine-tune your solar panels. You'd have the option of upgrading your Jandy check valve to a FlowVis if you wanted to. Which is a potential additional reason to go with Jandy now.

Last edited:

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

By the way, one more thing. Depending on how your solar system is setup and plumbed, that three-way you're replacing should be a special solar drain-down type. They allow water to drain down from the supply side of the panels, which can be important (again, depending on how your system is configured). Be sure you understand what all that means (if you don't already, that is) before you replace that valve.

If that isn't a true "solar" valve (it will have a small check valve built into the diverter) a simple solution is to drill a 1/4" hole in the center of the diverter to accomplish the same thing. Won't affect performance at all (you're going to close the isolation valves in winter). Since only Compool (now Pentair) made a valve like that, we would just drill that hole when we found a Jandy valve being used.

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I know that is done, but I never liked the idea. Yes, it will "accomplish" the same thing, allowing the panels to drain, but then it is essentially a large leak. No thanks. I don't have isolation valves and don't need them because I have a proper drain-down valve (with the check valve) on the supply line and a quality Jandy check valve on the return line. I'm not saying @1poolman1 is wrong, just that I wouldn't do it that way...If that isn't a true "solar" valve (it will have a small check valve built into the diverter) a simple solution is to drill a 1/4" hole in the center of the diverter to accomplish the same thing. Won't affect performance at all (you're going to close the isolation valves in winter). Since only Compool (now Pentair) made a valve like that, we would just drill that hole when we found a Jandy valve being used.

Thank you so much Dirk for your detailed response. And yes, the 3-way Pentair Valve is specifically for SOLAR. This is what we're replacing, with the same part >

www.inyopools.com

www.inyopools.com

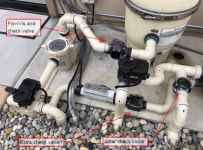

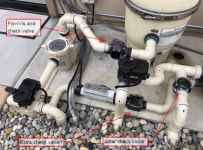

PS - do you happened to have a picture of what your PVC looks like at you point of your Filter where that Check Valve is installed? In the attachment above, the CHECK VALVE is the WHITE part in the Vertical position. So does it matter if the part you listed at Amazon is mounted Vertically? or must those be oriented Horizontally ? (We already have 1 like that outside on the Solar return line, horizontal)).

Pentair Solar Valve, 3-port, 2" X 2 1/2" (263047) - 6649-10 - INYOPools.com

263047 - SOLAR VALVE, 3-PORT, 2" X 2 1/2" (263047)

PS - do you happened to have a picture of what your PVC looks like at you point of your Filter where that Check Valve is installed? In the attachment above, the CHECK VALVE is the WHITE part in the Vertical position. So does it matter if the part you listed at Amazon is mounted Vertically? or must those be oriented Horizontally ? (We already have 1 like that outside on the Solar return line, horizontal)).

Last edited:

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Excellent! I believe that's the same valve I have.

A check valve can be installed any which way. Though there are some considerations. They have a clear top, so you can keep an eye on them, so however you orient it, be sure you can take advantage of its "looking glass." Be sure to leave a way to unscrew the top, if you ever need to service it.

If you think you might ever upgrade to a FlowVis, they are best read while in the horizontal position, so you'd want to mount your Jandy check in anticipation of that. Based on your plumbing pic, there is a simple way to do that, if you'd like to pursue that.

This pic is a little old, but I had already labeled it for some other post. What's not shown on the right is a gas heater, otherwise, this is all my pad plumbing. The solar valve is located just in front of the filter. The check valve labeled "Extra..." has since been removed. It's not necessary when using an SWG. The SWG replaced a tab feeder, and that old square check valve was needed in that case, between the tab feeder and the heater(s). The FLowVis has a curved face, that's where you read the flow rate. So in my setup, I stand to the right of it and look straight across it.

In my system, the check valve that keeps the solar panel water from backwashing the filter is located between my pump and filter (it's the FlowVis). It can also go between the solar valve and the filter, as you have it. It does it's job in either position. I just happened to have more room in the plumbing before the filter.

My solar pipes head underground before they pop up elsewhere to the roof. The actuator on my suction manifold controls the suction between my suction-side vac and my skimmer. The actuator closes off the suction port to the vac most hours of the day, and only activates the vac in the middle of the night (for safety concerns).

I don't have solar isolation valves, but I do have two hose bibs that I can use to drain most of the water out of my solar system. Water remains underground, but we have a zero frost line here, so it's not been an issue. Not trying to talk you out of isolation valves, but they are not required depending on climate.

A check valve can be installed any which way. Though there are some considerations. They have a clear top, so you can keep an eye on them, so however you orient it, be sure you can take advantage of its "looking glass." Be sure to leave a way to unscrew the top, if you ever need to service it.

If you think you might ever upgrade to a FlowVis, they are best read while in the horizontal position, so you'd want to mount your Jandy check in anticipation of that. Based on your plumbing pic, there is a simple way to do that, if you'd like to pursue that.

This pic is a little old, but I had already labeled it for some other post. What's not shown on the right is a gas heater, otherwise, this is all my pad plumbing. The solar valve is located just in front of the filter. The check valve labeled "Extra..." has since been removed. It's not necessary when using an SWG. The SWG replaced a tab feeder, and that old square check valve was needed in that case, between the tab feeder and the heater(s). The FLowVis has a curved face, that's where you read the flow rate. So in my setup, I stand to the right of it and look straight across it.

In my system, the check valve that keeps the solar panel water from backwashing the filter is located between my pump and filter (it's the FlowVis). It can also go between the solar valve and the filter, as you have it. It does it's job in either position. I just happened to have more room in the plumbing before the filter.

My solar pipes head underground before they pop up elsewhere to the roof. The actuator on my suction manifold controls the suction between my suction-side vac and my skimmer. The actuator closes off the suction port to the vac most hours of the day, and only activates the vac in the middle of the night (for safety concerns).

I don't have solar isolation valves, but I do have two hose bibs that I can use to drain most of the water out of my solar system. Water remains underground, but we have a zero frost line here, so it's not been an issue. Not trying to talk you out of isolation valves, but they are not required depending on climate.

Thank you so much for that detail. Helps me a lot. I'm in the SF BAY AREA. So also don't have SOLAR isolation valves - just a hose bib for putting air in the system to drain as necessary. So that Solar Check Valve you have is not rated at "Lb. Tension", right? That's what started my question based on looking at this valve: Flo Control White Check Valve 2" - 1/2 lb. w/ Unions - 170020 - INYOPools.com

If you scroll down to the FEATURES section, it specifically talks about higher tension available (2 lb) for SOLAR ROOF panels. But maybe because this model uses "springs", vs those Flaps in check valves like you have??? TYVM

If you scroll down to the FEATURES section, it specifically talks about higher tension available (2 lb) for SOLAR ROOF panels. But maybe because this model uses "springs", vs those Flaps in check valves like you have??? TYVM

PS - Dirk, what make/model is that SOLAR Check Valve ??? TIA

These are my options that I'm looking at ... they are rated at 1/2 lb or 2 lb.

www.inyopools.com

www.inyopools.com

These are my options that I'm looking at ... they are rated at 1/2 lb or 2 lb.

Pool Check Valves - Spa Check Valve - INYOPools.com

Pool & Spa Check Valves at discount prices - INYOpools.com

Last edited:

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

As I mentioned, I've never read about spring tension in a pool plumbing check valve, or why you'd need more or less. My intuition about the Jandy checks is that it is the force of the water pressure that keeps them closed when they need to be closed. The spring (which the Jandy's do have) only needs to be strong enough to keep the flapper closed when the pump is off, so that when the pump starts, it's already in the closed position, and not just loose.

There are two "degrees" of pressure that would open the flap on a solar return check. (1) When the solar system is active and the pump is pushing water through the system, and (2) when the pump is off and the water is draining out of the panels, so much less pressure. A stronger spring would mean (A) when the pump is on, it has to work harder to open the flap, creating some amount of unnecessary resistance (and some slight amount of energy loss), and (B) when the pump is off and the panels are draining, a stronger spring would close sooner than a weaker one and trap some amount of extra water above the check valve. Neither of which you want, though neither is any sort of big problem.

If this use case, I can't see how a stronger spring is going to be better. Regardless, I don't think Jandy checks have the option. I assume that Jandy has figured out the proper tension: just enough to keep the flap closed when needed, and not too much to cause undue restriction to flow. You're very likely overthinking this...

There are two "degrees" of pressure that would open the flap on a solar return check. (1) When the solar system is active and the pump is pushing water through the system, and (2) when the pump is off and the water is draining out of the panels, so much less pressure. A stronger spring would mean (A) when the pump is on, it has to work harder to open the flap, creating some amount of unnecessary resistance (and some slight amount of energy loss), and (B) when the pump is off and the panels are draining, a stronger spring would close sooner than a weaker one and trap some amount of extra water above the check valve. Neither of which you want, though neither is any sort of big problem.

If this use case, I can't see how a stronger spring is going to be better. Regardless, I don't think Jandy checks have the option. I assume that Jandy has figured out the proper tension: just enough to keep the flap closed when needed, and not too much to cause undue restriction to flow. You're very likely overthinking this...

No idea. Sorry. I kinda doubt Pentair has more than one model. Why?PS - Dirk, what make/model is that SOLAR Check Valve ??? TIA

- Nov 12, 2017

- 11,972

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.