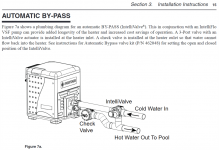

Im looking for validation that if I follow the attached plumbing diagram, I can successfully use the Pentair CVA-24L, 2-Port Valve Actuator, 90 Degree Rotation, 24v instead of the Intellivalve?

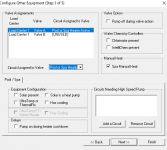

My plan would be to use the valve controller on the Easytouch 8 and assign to "VALVE A" to "Pool or Spa Heater Active" to automatically change from "divert" mode to "heater" mode ...

Just need confirmation / Validation this would not cause any inadvertent or unforeseen damages. (ie. do I need to turn off pump, program delays, etc.?)

What about cool down?

Would this program only work if "heat" is applied (you can be in spa mode, but no heater if the temp is 70* and water is 80* - relevant if I wanted to schedule a daily cycle of the water through heater)

My plan would be to use the valve controller on the Easytouch 8 and assign to "VALVE A" to "Pool or Spa Heater Active" to automatically change from "divert" mode to "heater" mode ...

Just need confirmation / Validation this would not cause any inadvertent or unforeseen damages. (ie. do I need to turn off pump, program delays, etc.?)

What about cool down?

Would this program only work if "heat" is applied (you can be in spa mode, but no heater if the temp is 70* and water is 80* - relevant if I wanted to schedule a daily cycle of the water through heater)