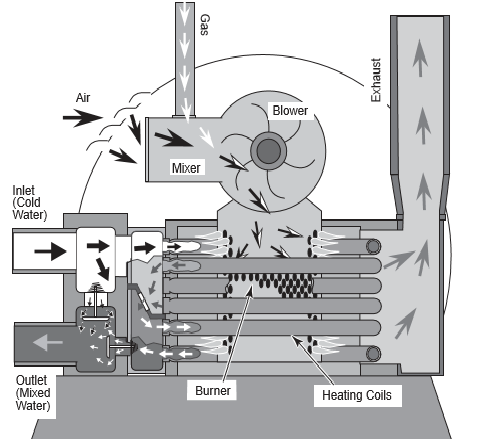

I had a pool guy install a custom fully automated By-Pass of my pool heater. I have pool solar so I use the heater as a heat boost occasionally for the spa only. I can now operate the heater Bypass on and off remotely. I use it in the spa, with my phone by way of the Jandy iAuqualink 2.0. I use it If I need a quick bump in temperature. In addition, I don't have to worry about my heater shedding cooper and staining in my pool when the chlorine levels get too high. I have had heater related plaster staining from time to time. I know it was a highly unusual request. And most pool repair guys didn't want to attempt it. I had a devil of a time finding someone who would attempt it. But I found a guy (finally) who knew exactly what to do. It was refreshing to find someone who really knows his stuff about pool equipment and not afraid to tackle a very uncommon request. He used 2 check valves and a Jandy valve actuator. Work great!

Automated Heater Bypass

- Thread starter sjungers

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looks neat!!

But, understand, it is low pH not high chlorine that erodes heater cores to put copper in the water. With water sitting in the heater being bypassed, I wonder how the pH will shift over time? @JoyfulNoise, any thoughts?

But, understand, it is low pH not high chlorine that erodes heater cores to put copper in the water. With water sitting in the heater being bypassed, I wonder how the pH will shift over time? @JoyfulNoise, any thoughts?

What's the reason for the top check valve?

You should probably use a flow switch instead of the heater pressure switch to make sure that the heater doesn't fire with no flow.

In my opinion, all heaters should have an automatic bypass.

That way you can get rid of the thermal regulator, which causes head loss.

The heat exchanger should be redesigned as a single pass system for less head loss.

A double pass system can be used with a stacked tube design where you have two layers of tubes with the top layer center of tubes in line with the gaps between the bottom tubes.

You should probably use a flow switch instead of the heater pressure switch to make sure that the heater doesn't fire with no flow.

In my opinion, all heaters should have an automatic bypass.

That way you can get rid of the thermal regulator, which causes head loss.

The heat exchanger should be redesigned as a single pass system for less head loss.

A double pass system can be used with a stacked tube design where you have two layers of tubes with the top layer center of tubes in line with the gaps between the bottom tubes.

- May 23, 2015

- 24,411

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I echo what @JamesW said....one too may check valves

Modern gas pool heaters are not very well designed in terms of their hydraulics or heat transfer. But I think if you were to redesign them to be more efficient, the cost would go through the roof. As it is right now, peoples' eyes water when they see the $3,000 price tag just for the heater itself let alone any installation costs....it's probably the costliest piece of equipment that can be added to a pool pad.

Most heaters are designed to operate in a bypass flow arrangement when they are cold, so water does sit inside the exchanger no matter if the heater is in the loop or not. You have to turn the heater on and get it warmed up before water flows through the coils. The pH shouldn't really drift that much when the heater is just sitting there with water in it. But bypass loops are a good thing to have and, honestly, every pool plumber should install a heater with one in case service is needed. If I were smarter back in the day, I would have had one installed with my heater.

Modern gas pool heaters are not very well designed in terms of their hydraulics or heat transfer. But I think if you were to redesign them to be more efficient, the cost would go through the roof. As it is right now, peoples' eyes water when they see the $3,000 price tag just for the heater itself let alone any installation costs....it's probably the costliest piece of equipment that can be added to a pool pad.

Most heaters are designed to operate in a bypass flow arrangement when they are cold, so water does sit inside the exchanger no matter if the heater is in the loop or not. You have to turn the heater on and get it warmed up before water flows through the coils. The pH shouldn't really drift that much when the heater is just sitting there with water in it. But bypass loops are a good thing to have and, honestly, every pool plumber should install a heater with one in case service is needed. If I were smarter back in the day, I would have had one installed with my heater.

Last edited:

Looks neat!!

But, understand, it is low pH not high chlorine that erodes heater cores to put copper in the water. With water sitting in the heater being bypassed, I wonder how the pH will shift over time? @JoyfulNoise, any thoughts?

When my pool was built, many years ago, the pool service guy put a large chlorine tab dispenser inline and directly into the pipe towards the heater. Over time I got blue patches of copper on my white plaster. I found out much later that the chlorine was dissolving the copper in my heater.Or better stated the acid component of the chlorine. I removed it and my problem was solved.

Last edited:

What's the reason for the top check valve?

You should probably use a flow switch instead of the heater pressure switch to make sure that the heater doesn't fire with no flow.

In my opinion, all heaters should have an automatic bypass.

That way you can get rid of the thermal regulator, which causes head loss.

The heat exchanger should be redesigned as a single pass system for less head loss.

A double pass system can be used with a stacked tube design where you have two layers of tubes with the top layer center of tubes in line with the gaps between the bottom tubes.

I have a large Teledyne Laars ESC II heater. I believe has a pressure switch of some kind. All I know is it did not fire without water flow. I know because I inadvertently tried it. I think you are correct. I believe I will install a flow switch, as well, just to add a little redundancy protection.

I would be just guessing about the top check valve. But it might have something to do with the pool solar backflow. That circuit is not showing in the photo.

Last edited:

- Feb 6, 2015

- 6,100

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

When my pool built, many years ago, the pool service guy put a large chlorine tab dispenser inline and directly into the pipe towards the heater. Over time I got blue patches of copper on my white plaster. I found out much later that the chlorine was dissolving the copper in my heater. I removed it and my problem was solved.

Actually it was the acidity of the tabs that caused your issue and not the chlorine in the tabs. If a chlorine tab dispenser is installed, it should always be after the heater in the return line - and there should be a check valve placed inline between the heater and the chlorine tab dispenser.

When my pool was built, many years ago, the pool service guy put a large chlorine tab dispenser inline and directly into the pipe towards the heater. Over time I got blue patches of copper on my white plaster. I found out much later that the chlorine was dissolving the copper in my heater.Or better stated the acid component of the chlorine. I removed it and my problem was solved.

Kind of....

Trichlor tablets are acidic, they reduce the pH of the water. As you found, because of hte way tabs reduce the pH, a tablet chlorinator should always be in the system as the last thing before the water is returned to the pool.

But, Matt has indicated the water sitting in the heater should not have much shift in pH so I feel better.

- May 23, 2015

- 24,411

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Those old Laars heaters had a way of melting PVC pipes when flow from the pump would stop before the heater had a chance to cool off. Be very careful that the automated bypass never activates when the heater is running. The heater will shut off if the flow stops (hopefully) but the water in the heat exchanger will boil from the residual heat and it could easily melt all the PVC attached to the header.

You could set the bypass valves limit switches so that the valve is always a little bit open. That way there’s always a trickle of water flowing to the heater.

You could set the bypass valves limit switches so that the valve is always a little bit open. That way there’s always a trickle of water flowing to the heater.

Matt, you are absolutely correct about that. Thanks for the suggestion. And I will consider that adjustment on that JVA. I know the iAuqualink board has a cool-down mode on-off dip switch for that very reason. That is, under normal circumstances. In this case, although that cool down mode will extend the pump run time, it obviously won't prevent the bypass valve from closing if I turn it off prematurely.

After shutting off the heater I always run water through the heater before closing the JVA bypass. But... if I forget, it is a real problem I am aware of.

After shutting off the heater I always run water through the heater before closing the JVA bypass. But... if I forget, it is a real problem I am aware of.

Last edited:

vsman

Well-known member

do you have a reference for this? i.e. bypass when water is cold? I could not find it in any of the manuals.I echo what @JamesW said....one too may check valves

Most heaters are designed to operate in a bypass flow arrangement when they are cold, so water does sit inside the exchanger no matter if the heater is in the loop or not. You have to turn the heater on and get it warmed up before water flows through the coils.

The thermal regulator blocks the exit of the heat exchanger until the heater fires and the water warms up.

While the thermal regulator is closed, all of the water goes through the internal bypass.

While the thermal regulator is closed, all of the water goes through the internal bypass.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

![DSCF0500[1].JPG](/data/attachments/148/148896-5d69bd7a625f1c5d1dea5b36b9957c1a.jpg)