We have super clean water in West TN and this salt cell has honestly given us problems from day 1. Having to replace every 2-3 years even though internals are crystal clean and I'm meticulous about watching chemical levels. Latest go around, I went through Jandy's technician guide step-by-step pushing test buttons on main control board & measuring point voltages. Everything was well within spec as shown in guide. We're simply not getting any chlorine. Like NONE. Here are highlights of most recent bout:

~Vol

- Controller set at 90%-100%. Off and on throughout day it shows as fine, but multiple times per day pops voltage error 123. Is this typically a BOARD or CELL problem? My gut says cell as when it's in normal operation @ 100%, cell terminals are receiving north of 25VDC. Hope this is the case as I already have (yet another) replacement cell on order!

- More recently I can set to 100% and it will show fine for a few hours, but now it doesn’t show intermittent 123 error. Somehow resets itself to 0% setpoint without showing any errors, I guess since it’s not calling for the cell to operate. Again, BOARD or CELL? No idea what’s causing random reset to 0% as it’s never done that before.

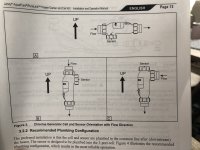

- Previous replacement was done by pool contractor under warranty around 2 years ago. New Jandy cell looks identical but shows a weird “R” model number with “N/A” for the serial. I was advised this is just how warranty pieces are delivered. But contractor had to completely re-pipe to install it. All 3 connections on old unit were exact same size, but this one has inlet/outlet connections *slightly* smaller than bottom tri-sensor connection, ballpark 1/8” smaller, but enough to require different size threaded collar. Was that a permanent global product design change, or something specific to warranty replacements? Now that I’ve ordered new off-the-shelf unit, I don’t want to re-pipe all over again because connectors don’t fit!

~Vol