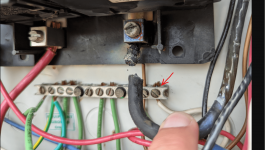

The line in to my power center keeps melting. The only thing that changes is a VSP pump and a voltage surge protector all on the same side.

Any one have ideas on what is going on?

I'm trying to get an electrician to look at it too, but I am an EE and don't mind a DIY if it seems reasonable. Just don't know what the root cause is here.

Any one have ideas on what is going on?

I'm trying to get an electrician to look at it too, but I am an EE and don't mind a DIY if it seems reasonable. Just don't know what the root cause is here.