- Nov 12, 2017

- 12,661

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

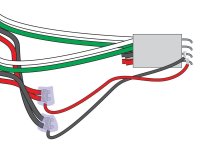

That is the exact fix we devised if the connector is already fried. I illustrated that a while ago, I just didn't show it to you yet, to keep things simple:Indeed. I meant to keep red and black separate. Question, what would happen if you (as an example) cut the pair of red wires and terminate them into a Wago connector and then have a single wire going to (cheap) board connector. The other red wire I would just cut close to connector. Kind of like what @Turbo1Ton did in this picture, except I would leave the connector in place.

And here's yet another version, if, say, the connector is working, but is showing signs of failure, or if you want to do a preemptive fix that will work even if the connector someday goes out (it won't matter if it does). The only down side to these two fixes is that you can no longer just unplug and swap in a new board, you'd have to do some de-soldering.

The reason the splices look a little strange is because I illustrated these the way I would splice them. Not with Wagos or wirenuts, and I would not cut the wires at all, rather I'd just strip them, wrap them together with a smaller gauge wire that would then double as the jumper to the circuit board pins. Then I would solder the wraps, to make them corrosion proof, and finally insulate them with epoxy or some other such material.

It's not standard, but it's just the way I do.

Wagos and wire nuts should work fine, but remember, they are just physical connections, theoretically still prone to corrosion and loose connections. For me, soldering eliminates all that and provides the best path for higher current. We discuss Wagos and wire nuts because soldering is something not everybody can or wants to do.

@Turbo1Ton took it one step further and removed the white connector altogether. That's how I fixed mine, too. But he was smart enough to reduce the wire size with Wagos before soldering to the board. I wish I had thought of that! I actually soldered the big fat wires to the board. I would definitely not recommend that. It was a small miracle I got that to work, and taxed my soldering skills to the max!

So there are several ways to skin this cat. All with advantages and disadvantages.