Thank you for the info. It’s reassuring that the hole saw did the job and the enclosure didn’t crack or something. I will get an identical saw from Home Depot. I was looking for a one with a higher density of teeth, but couldn’t find.Yep, it was a Milwaukee 4 1/2" Hole Dozer.

I was a little worried that I would mess up but everything turned out fine.

"Plan & measure 15 times". Cut Once...

Thanks..

r.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rstrouse

Well-known member

Keep the pressure on the drill low at the end of the process and you will get a cleaner hole.

Thanks for advice. The process went very well, the cutouts are perfect. First, I locked the enclosure between two heavy boxes and drilled the pilot hole with a regular 1/4-in bit. Then attached the Hole Dozer and pushed the pilot bit into the hole until the teeth of the saw rested on the surface. Finally, started drilling.

I declare the Hole Dozer the official saw for fiberglass enclosures

I declare the Hole Dozer the official saw for fiberglass enclosures

Attachments

- Mar 5, 2020

- 3,221

- Pool Size

- 66000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Astral Viron V35

I'm toying with the idea of getting the Atlas system. One thing I am not sure about is that I don't have a main drain and I am only drawing water through the skimmer (unless the suction cleaner is running through a suction plate - 40 years old pool, not too much I can do about it apart from gutting it).

When taking our water samples, we always make sure to take them from at least elbow deep, but with probes in the plumbing I would basically take my samples from the water surface.

Have you guys have any experience how much pH and ORP readings change when switching between skimmer and main drain?

After conversion from USD to AUD plus international shipping, or going through a local distributor, the cost is getting a bit outside of the range where you want to buy a system that would not actually work properly under my circumstances. I could downgrade to the consumer grade probes to Daive some money, but I don't have too much confidence in them.

When taking our water samples, we always make sure to take them from at least elbow deep, but with probes in the plumbing I would basically take my samples from the water surface.

Have you guys have any experience how much pH and ORP readings change when switching between skimmer and main drain?

After conversion from USD to AUD plus international shipping, or going through a local distributor, the cost is getting a bit outside of the range where you want to buy a system that would not actually work properly under my circumstances. I could downgrade to the consumer grade probes to Daive some money, but I don't have too much confidence in them.

rstrouse

Well-known member

It really won't make a difference. You will simply set your setpoints according to where you want the levels to sit.

- Mar 5, 2020

- 3,221

- Pool Size

- 66000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Astral Viron V35

At this stage I will use the system only to monitor parameters, especially when away. But I guess the same philosophy applies, it's not absolute values I'm after, but relative changes. Would still be interesting to see if there are differences between pulling water from the surface vs. the bottom of the pool. But I'll work that out soon, just finalised my order for the wifi kit with the combined industrial pH/T/ORP probe.

Katodude

Silver Supporter

- Aug 22, 2017

- 2,996

- Pool Size

- 15000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I am measuring ph from the skimmer. It’s dead on. Cant speak for ORP.

Also just reminded me I need to calibrate my pH sensor.

I can also vouch that the industrial probe is very accurate and goes a long time between calibration.

Also just reminded me I need to calibrate my pH sensor.

I can also vouch that the industrial probe is very accurate and goes a long time between calibration.

sile16

New member

How do you know the fill level of your acid tank ? Are you just filling it and keeping track of how much you dispense? I just ordered the atlas pool kit, and about to order the conductivity sensor, but I just saw the pressure sensor on your sand filter would be nice to monitor... since I already have the free air temp from pentair I may pull the temp probe and use the EC or maybe I'll get a second kit .... not sure.

@sile16How do you know the fill level of your acid tank ? Are you just filling it and keeping track of how much you dispense?

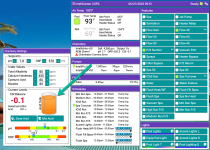

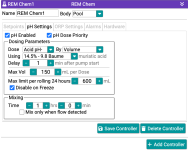

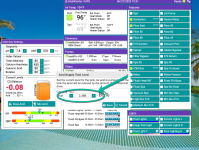

With regards to my setup (njspC/REM)... I can either take a quick peek at the Acid Tank representation in Chemistry Settings in my njspC dashPanel or look at my "Acid Tank = Remaining, Gauge in my Grafana dashboard.

The REM software knows how much MA is being dispensed based on user-defined settings within the njspC dashPanel.

When I add my 50/50 mixture of MA/H2O to the MA Tank, I then just click on the tank representation in the software and the following pop-up appears. I just tell njspC how much I added by adjusting the new tank level and the software keeps track of everything and does the rest. It's really quite ingenious and simple to maintain.

I have no experience with the Atlas-Scientific "WiFi Pool Kit", if that is what you are referring to. I'm really not up-to-speed on who might be using that kit.I just ordered the atlas pool kit, and about to order the conductivity sensor, but I just saw the pressure sensor on your sand filter would be nice to monitor... since I already have the free air temp from pentair I may pull the temp probe and use the EC or maybe I'll get a second kit .... not sure.

Most of us that ventured down this "rabbit hole", are using the Atlas-Scientific Industrial Probes and EZO circuits in combination with Whitebox Stackable Tentacle T3 “sensor host” add-on boards or otherwise known as “shields” mounted on a Raspberry Pi.

Everyone's setup is slightly different but as for me, I'm currently running the following probes/sensors.

Atlas-Scientific Industrial Conductivity (EC) Probe K 1.0

Atlas-Scientific Industrial pH Probe

Atlas-Scientific Industrial ORP Probe

Atlas-Scientific PT-1000 Temperature Sensor

Atlas-Scientific EZO_PRS Embedded Pressure Sensor (Filter Pressure)

Atlas-Scientific EZP-HUM Humidity Sensor NOTE: This probe provides Humidity, Dew Point and Air Temp. It was a little "overkill" but I decided to do it - " just because I could"

If you may be interested in nodejs-poolController and REM, please check out the links below. The developers over there are very knowledgeable and helpful.

https://github.com/tagyoureit/nodejs-poolController

https://github.com/tagyoureit/nodejs-poolController/wiki

https://github.com/rstrouse/relayEquipmentManager

https://github.com/rstrouse/relayEquipmentManager/wiki

Hope you find this useful.

r.

Last edited:

jonpcar

Bronze Supporter

Ron, regarding the above probe…is this for salt readings? …and how closely does it match the chemical test kits? It is not very clear from the description as it seems that it might include a few other things in its reading. Can these other things be “scrubbed out” to reliably determine salt concentration? You’ve probably already described this somewhere in this thread, haha. Thanks!Atlas-Scientific Industrial Conductivity (EC) Probe K 1.0

Hi Jon,Ron, regarding the above probe…is this for salt readings? …and how closely does it match the chemical test kits? It is not very clear from the description as it seems that it might include a few other things in its reading. Can these other things be “scrubbed out” to reliably determine salt concentration? You’ve probably already described this somewhere in this thread, haha. Thanks!

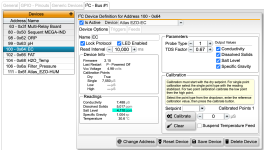

Yes, the EC probe is for salt readings.

Here is how I use it.

1. First I properly calibrate the probe and make the adjustment in the REM software.

2. Then I compare the Taylor Sodium Chloride drop test results and what the Salt Level is indicating in the REM software. The software takes the conductivity reading and along with pool water temp, calculates the Dissolved Solids, Salt Level and Specific Gravity.

3. If there is much of a difference, I may make a slight adjustment to the conductivity within the calibration window so it more closely matches the Taylor drop test.

After that, it will continue to report the proper salt level, and every time I make a comparison between the two, the salt level reported in REM is usually about right on.

Pool temperature greatly effects the readings so it's important to ensure that the temperature feed is correct.

I hope that somewhat answers the question and hope you're staying cool now that our weather is back to "normal" for this time of year.

Take care...

r.

BTW, that salt level that is shown in the REM software is then shown on my njspC dashPanel as well as fed to my Grafana dashboard. So, it's all pretty user friendly once it's all set up.

Last edited:

- Mar 5, 2020

- 3,221

- Pool Size

- 66000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Astral Viron V35

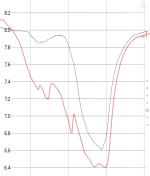

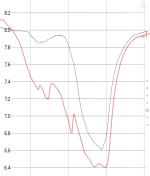

Well, that was quite disappointing. That Wifi Kit was pretty much useless. I bought it via an Australian distributor. Turned out they sent me an older model to start with. Could have lived with that, but something in the electronics is very temperature sensitive. Here a screenshot with pH signal of the probe in the pool pipes, 2 days overlaid in one graph:

Each day around noon, the hit hit for an hour or so the control box. In that time the pH signal crashed.

I then did a test where I placed the probe into pH 4 buffer solution which I kept at constant temperature. I then changed the room temperature where the Wifi Kit was placed in, and saw the same behaviour.

Atlas was useless in the process. I first got in touch with them about some general questions, which they were quite helpful with. As soon as I mentioned that something is not right, they stopped replying.

Aussie distributor was very good about it, got a refund in the end.

Each day around noon, the hit hit for an hour or so the control box. In that time the pH signal crashed.

I then did a test where I placed the probe into pH 4 buffer solution which I kept at constant temperature. I then changed the room temperature where the Wifi Kit was placed in, and saw the same behaviour.

Atlas was useless in the process. I first got in touch with them about some general questions, which they were quite helpful with. As soon as I mentioned that something is not right, they stopped replying.

Aussie distributor was very good about it, got a refund in the end.

jonpcar

Bronze Supporter

For those that have implemented some form of the manifold loop (or in-line placement) for testing hardware (ph, ORP, salt probes), do you see any reading sensitivities to the volume of water flowing past the probes? I’m trying to figure out the best place to put a manifold in my (future TBD) system and am wondering if variations in the water pressure/flow impact the consistency of the probe readings.

Jon,

If you recall my setup, I'm using a "bypass" manifold where by adjusting a Jandy valve, I can control (reduce) the amount of water that flows past the probes/sensors. In the plumbing scheme, it's located after the filter but before the heater bypass, acid injection fitting and chlorinator.

I installed a flow-Vis metering device in that manifold, so I could get a somewhat approximate idea of the flow past the probes/sensors.

At 40 GPM pump flow (1500 RPM) for example, the water flow past the sensors is approximately 10-15 GPM. I haven't experienced any problems with this type of setup. I believe the Atlas Industrial sensors can handle much more that however.

Hope this helps a bit.

r.

If you recall my setup, I'm using a "bypass" manifold where by adjusting a Jandy valve, I can control (reduce) the amount of water that flows past the probes/sensors. In the plumbing scheme, it's located after the filter but before the heater bypass, acid injection fitting and chlorinator.

I installed a flow-Vis metering device in that manifold, so I could get a somewhat approximate idea of the flow past the probes/sensors.

At 40 GPM pump flow (1500 RPM) for example, the water flow past the sensors is approximately 10-15 GPM. I haven't experienced any problems with this type of setup. I believe the Atlas Industrial sensors can handle much more that however.

Hope this helps a bit.

r.

Katodude

Silver Supporter

- Aug 22, 2017

- 2,996

- Pool Size

- 15000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I swear, I am ready to buy you a ticket to Florida and pump you full of whatever your favorite poison is just to have you help me re do my plumbing.

@Katodude

LOL... It's really not that bad.

It should be a "piece of cake" for someone with your skill sets!

The hard part is working up the motivation to tackle something like that.

The way I do it is this.... I figure out what materials I need and then I make the purchases.

Now that I got all of this material laying around my garage that I just paid X-$$$ for, then that is the motivation that I need to GETERDONE.

r.

Oh yea.... Winter would be the time to re-plumb the pool pad (at least for our climates).

LOL... It's really not that bad.

It should be a "piece of cake" for someone with your skill sets!

The hard part is working up the motivation to tackle something like that.

The way I do it is this.... I figure out what materials I need and then I make the purchases.

Now that I got all of this material laying around my garage that I just paid X-$$$ for, then that is the motivation that I need to GETERDONE.

r.

Oh yea.... Winter would be the time to re-plumb the pool pad (at least for our climates).

Last edited:

@MyAZPool you know that chlorinator label is mis-aligned. I didn't want to say anything but it has been bugging me.

Ha, I need to get out there in that 106 degree temp right now and get that corrected.

Need to keep the "developers" happy.

A person in the Air Force once told me that there are 4 types of people in the Air Force that you don't mess with or that you always need to be nice to.

IT

SECFOR

SERVICES

& MAINTENANCE

BTW, I thought of a new slogan for njspC the other day. "njspC - The "Energizer Bunny" of Pool Controllers!"

I don't think I've touched it or REM going on 2 years and it just keeps "marching on"

Thanks!!

r.

Last edited:

jonpcar

Bronze Supporter

Thanks @MyAZPool …that’s what I suspected with your NICE manifold setup. The issue I believe I will run into with my manifold will be due its placement (yet TBD) and it’s operation under wider differences in volume/pressure because I have 3+ return circuit paths to my pool: wall returns, IFCS, waterfalls, aerator (unimplemented). I DO want to monitor the pool balance during all those operations.

But those daily circuit operations have RPM ranges between 800-2700 and the operating pressure differentials across most of those “potential manifold locations” varies from between +0 up to 18 PSI. I’m gonna need a throttle

, but I don’t think it will allow the degree of consistent gpm volume control through the manifold that yours has.

Does your manifold gpm change dramatically when you operate your pump at 1000rpm vs 2700rpm? Your spa jets seem to operate on a different pump so not sure if you have such a wide operating RPM spread on your filtered pool pump system.

How about yours @Katodude? Your ph probe is in your main line…do it’s readings change when you adjust your RPM significantly (although I think ORP is more sensitive to this then pH from my understanding)?

Anyway, enough with hijacking this awesome thread…I will start a new thread at some point because I need to redo my pad plumbing for a number of changes that I am planning. My probe manifold placement will be one of those issues.

The one place that I believe would be best for me is a manifold that simply goes around the SWG and it’s flow switch. But I don’t know if there is enough back pressure caused by a SWG to force a minimum (??) gpm through such a bypass manifold. I could introduce additional back pressure (with a valve like yours) but hate to do that because it will be very inefficient for my IFCS.

I probably end up with a manifold more similar to @rstrouse ’s or segalions’s, but still not yet sure where to place its endpoints.

But those daily circuit operations have RPM ranges between 800-2700 and the operating pressure differentials across most of those “potential manifold locations” varies from between +0 up to 18 PSI. I’m gonna need a throttle

, but I don’t think it will allow the degree of consistent gpm volume control through the manifold that yours has.

Does your manifold gpm change dramatically when you operate your pump at 1000rpm vs 2700rpm? Your spa jets seem to operate on a different pump so not sure if you have such a wide operating RPM spread on your filtered pool pump system.

How about yours @Katodude? Your ph probe is in your main line…do it’s readings change when you adjust your RPM significantly (although I think ORP is more sensitive to this then pH from my understanding)?

Anyway, enough with hijacking this awesome thread…I will start a new thread at some point because I need to redo my pad plumbing for a number of changes that I am planning. My probe manifold placement will be one of those issues.

The one place that I believe would be best for me is a manifold that simply goes around the SWG and it’s flow switch. But I don’t know if there is enough back pressure caused by a SWG to force a minimum (??) gpm through such a bypass manifold. I could introduce additional back pressure (with a valve like yours) but hate to do that because it will be very inefficient for my IFCS.

I probably end up with a manifold more similar to @rstrouse ’s or segalions’s, but still not yet sure where to place its endpoints.

Jon,Thanks @MyAZPool …that’s what I suspected with your NICE manifold setup. The issue I believe I will run into with my manifold will be due its placement (yet TBD) and it’s operation under wider differences in volume/pressure because I have 3+ return circuit paths to my pool: wall returns, IFCS, waterfalls, aerator (unimplemented). I DO want to monitor the pool balance during all those operations.

But those daily circuit operations have RPM ranges between 800-2700 and the operating pressure differentials across most of those “potential manifold locations” varies from between +0 up to 18 PSI. I’m gonna need a throttle

, but I don’t think it will allow the degree of consistent gpm volume control through the manifold that yours has.

Does your manifold gpm change dramatically when you operate your pump at 1000rpm vs 2700rpm? Your spa jets seem to operate on a different pump so not sure if you have such a wide operating RPM spread on your filtered pool pump system.

How about yours @Katodude? Your ph probe is in your main line…do it’s readings change when you adjust your RPM significantly (although I think ORP is more sensitive to this then pH from my understanding)?

Anyway, enough with hijacking this awesome thread…I will start a new thread at some point because I need to redo my pad plumbing for a number of changes that I am planning. My probe manifold placement will be one of those issues.

The one place that I believe would be best for me is a manifold that simply goes around the SWG and it’s flow switch. But I don’t know if there is enough back pressure caused by a SWG to force a minimum (??) gpm through such a bypass manifold. I could introduce additional back pressure (with a valve like yours) but hate to do that because it will be very inefficient for my IFCS.

I probably end up with a manifold more similar to @rstrouse ’s or segalions’s, but still not yet sure where to place its endpoints.

Yea, @rstrouse (as well as a few others that have similar setups) has a really nice sensor manifold setup. Especially, if "space" is a consideration.

He really explains how he set up his flow cell in great detail here...

https://github.com/tagyoureit/nodejs-poolController/wiki/DIY-REM-Chem-Controller

r.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.