- May 23, 2015

- 25,695

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Two thoughts to consider when talking to the gas installer -

1. High pressure (2psi) means having regulators at the equipment pad and the house line. Regulators can fail. So make sure that you’re ok with the cost of adding the regulator as well as the quality of them. Cheap regulators abound and you’d rather not have to replace them if you can avoid it.

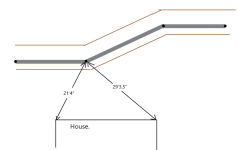

2. Check building codes or ask the plumber what the building codes are for buried gas lines. Some municipalities do not allow high pressure lines to be buried while others don’t care. We went with low pressure because high pressure lines can’t be buried and there was no way to get to the equipment pad from our gas supply using above ground piping.

The gas installer should know the answers to all those questions. Just make sure you get the answers from them.

1. High pressure (2psi) means having regulators at the equipment pad and the house line. Regulators can fail. So make sure that you’re ok with the cost of adding the regulator as well as the quality of them. Cheap regulators abound and you’d rather not have to replace them if you can avoid it.

2. Check building codes or ask the plumber what the building codes are for buried gas lines. Some municipalities do not allow high pressure lines to be buried while others don’t care. We went with low pressure because high pressure lines can’t be buried and there was no way to get to the equipment pad from our gas supply using above ground piping.

The gas installer should know the answers to all those questions. Just make sure you get the answers from them.