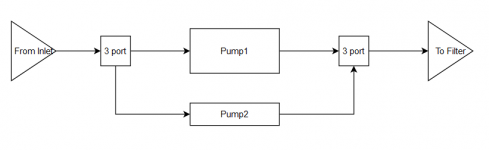

I have a 2nd pump plumbed in parallel with the 1st. The 2nd pump is smaller than the 1st. I only use 1 at a time, and I manually switch both 3 port valves to block off inlet and outlet of the pump not in use.

My question is, If I want to automate the switching between the 2 pumps, do I need an actuator on each 3-port and replicate what I do now manually, or can I open one 3 port to both pumps and put an actuator on the other to switch between them. I already have the electrical switching in place, so just asking about the water flow.

If I just use 1 actuator should I put it on the inlet or outlet 3-port?

If the actuator fails and the pump electrically switches to the other, I'll automatically detect that no water is flowing and switch off the pump after 30 seconds, but for that time period, the pump is either pushing or pulling against a closed valve. Is one better than the other?

Cheers.

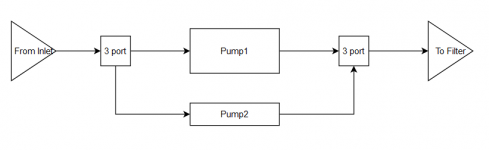

My question is, If I want to automate the switching between the 2 pumps, do I need an actuator on each 3-port and replicate what I do now manually, or can I open one 3 port to both pumps and put an actuator on the other to switch between them. I already have the electrical switching in place, so just asking about the water flow.

If I just use 1 actuator should I put it on the inlet or outlet 3-port?

If the actuator fails and the pump electrically switches to the other, I'll automatically detect that no water is flowing and switch off the pump after 30 seconds, but for that time period, the pump is either pushing or pulling against a closed valve. Is one better than the other?

Cheers.