16 July 2024 Finishing Up my OB Pool

- Thread starter setsailsoon

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

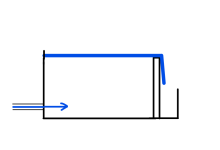

There's about 5.5' of elevation difference from normal basin level to the pump suction. Then the returns are all back to the bottom of the pool which are under 4'-6' of water so say 5'. That's 10' of head plus the friction losses... returns are 2 1/2" pipe. Seems like more than 15' of total dynamic head but I'll check pressures to verify what we get. But I see your point. Flow should be pretty high. I thought 5/16" was well over 200 gpm from the weir calcs you did a while back. If I have that plus close to that for the ~60' of gutters we may well have 280 gpm right now.The pump should be able to hit 280 GPM and I do not think that you are getting anywhere close to that.

View attachment 585303

Chris

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

May have been better but too late for that now!For the returns, I would have done (3) 3" pipes coming in low and horizontal at the wall opposite of the Infinity edge.

View attachment 585305

How many 2.5" pipes?returns are 2 1/2" pipe.

In my opinion, you might be at 170 to 190 gpm.If I have that plus close to that for the ~60' of gutters we may well have 280 gpm right now.

I know, just for future reference.May have been better but too late for that now!

The static head loss is the difference in height from the surface of the pool water to the surface of the trough water.There's about 5.5' of elevation difference from normal basin level to the pump suction. Then the returns are all back to the bottom of the pool which are under 4'-6' of water so say 5'. That's 10' of head plus the friction losses.

The rest of the height differences are irrelevant.

The dynamic friction losses are based on the pipe sizes and flow rates.

I do not think that you are anywhere near 5/16" lift.I thought 5/16" was well over 200 gpm from the weir calcs you did a while back.

I think that we were looking at 250 GPM for the 5 hp pump and 120 GPM for the filter pump, which would put the flow at about 370 GPM.May have been better but too late for that now!

Using the 8 ft/sec rule, (2) 3" returns would allow 368 GPM.

(2) 3" returns for the Infinity edge would have been good.

Maybe branch off the 3" returns to (2) 2" returns each near the pool.

(2) 2" Returns for the Filtration Pump would have been good for the Filter pump return.

In any case, it is what it is.

Pipe Size and Flow Rates.

You want to keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump.| Pipe Size | 6 ft/sec | 8 ft/sec |

|---|---|---|

| 1.5" | 38 GPM | 51 GPM |

| 2" | 63 GPM | 84 GPM |

| 2.5 | 90 GPM | 119 GPM |

| 3.0" | 138 GPM | 184 GPM |

| 4.0" | 235 GPM | 312 GPM |

Last edited:

- May 23, 2015

- 25,718

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I’d play with the fittings on those four low floor returns near the infinity wall. You could put directional eyeballs on them and direct the water flow towards the house side of the pool. That would keep the surface water near the infinity edge more still. Sure, you’ll lose some flow from the added head loss of the directional eyeballs … but, in all honesty, you’re running a 5HP pump and you’ve got an amazing amount of flow. The point is to get the aesthetic the way you want it, not to achieve maximum flow of water over the edge. I’d trade a little less efficiency if it meant getting the edge aesthetic the way I want …

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

I know, just for future reference.

The static head loss is the difference in height from the surface of the pool water to the surface of the trough water.

The rest of the height differences are irrelevant.

The dynamic friction losses are based on the pipe sizes and flow rates.

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

I'll try to send you a photo next time I get back in. I measured it close up with a ruler and the water level was clearly 5/16" all around the pool. Wish I had a go pro!I do not think that you are anywhere near 5/16" lift.

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Definitely agree Matt... just curious a little how much water I'm really moving. It's a pretty massive amount now that the heater is out of the loop. Hope I didn't damage the heater! At least it never leaked. Also, I'll have to watch how much I run it at the max each day... it's almost 4000 watts.I’d play with the fittings on those four low floor returns near the infinity wall. You could put directional eyeballs on them and direct the water flow towards the house side of the pool. That would keep the surface water near the infinity edge more still. Sure, you’ll lose some flow from the added head loss of the directional eyeballs … but, in all honesty, you’re running a 5HP pump and you’ve got an amazing amount of flow. The point is to get the aesthetic the way you want it, not to achieve maximum flow of water over the edge. I’d trade a little less efficiency if it meant getting the edge aesthetic the way I want …

The trough depth difference will be a lot more accurate to determine lift.

Trying to accurately measure the lift at the pool edge is probably not possible.

When the pump is on, every gallon of water that goes out of the trough will go into the pool.

If the trough loses 100 gallons, the pool gains 100 gallons.

The volume difference plus the exact dimensions of the pool and trough will allow you to calculate the lift more accurately than trying to measure it at the Infinity Edge.

Trying to accurately measure the lift at the pool edge is probably not possible.

When the pump is on, every gallon of water that goes out of the trough will go into the pool.

If the trough loses 100 gallons, the pool gains 100 gallons.

The volume difference plus the exact dimensions of the pool and trough will allow you to calculate the lift more accurately than trying to measure it at the Infinity Edge.

Last edited:

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

I have 2 but they combine close to the pad. I remember checking to see what we needed for this and seems like 1 would have been over 15 ft/sec. but they do have to combine at some point close to the pump discharge. In hindsight I could have had two risers then combined.Are you using one 2.5" return or two 2.5" returns?

- Oct 25, 2015

- 5,826

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

15 June 2024 This is like starting up a chemical plant!

I've led the startup of a lot of chemical plants in my prior life and I have to say this pool with it's complicated hydraulics and automation is reminding me how difficult that was at times. Part of the difficulty was always working 12 hour+ shifts 'till we had the plant up and running reliably at design capacity. The pool startup has been similar in many ways. Here's where I am:

Chris

I've led the startup of a lot of chemical plants in my prior life and I have to say this pool with it's complicated hydraulics and automation is reminding me how difficult that was at times. Part of the difficulty was always working 12 hour+ shifts 'till we had the plant up and running reliably at design capacity. The pool startup has been similar in many ways. Here's where I am:

- Weather has been awful so haven't made any progress on the last 10% of pavers. As a result I'm still working in a sandy/muddy mess.

- Got the big pump re-plumbed last week to remove equipment from that loop. Putting the heater in that loop was pretty dumb. I should have known better. Will finish revising the smaller pump plumbing to get the heater in that loop today.

- Automation has made huge progress but a few technical issues remain that I'm sure will get worked out next couple of days. Thank goodness for generous time that @Katodude , @rstrouse and a few others are providing for that. Even though it's a little difficult for me I feel like I'm learning a LOT and I always enjoy that.

- We had a bad lightning strike close by the other day that may have fried my RS 485 on the big pump. It was working fine 'till then. These drives are notoriously sensitive. My brother had almost the same thing happen on his 3 hp Pentair but his model didn't have the digital I/O so he had to fork out $750 for a replacement drive. They aren't even available yet for my pump. I do have a surge suppressor in the power supply so I may get that covered. But that's a notoriously difficult process. In the meantime, I'm very fortunate the drive for these fancy vs pumps has capability to run with digital I/O. I'm hopeful I can run the small pump on RS485 and the large pump on digital I/O. That's the way I ran my previous vs speed pump. Worked fine.

- Looks like the paver work will resume next week and the tile guy will finish the gutter plumbing. Will be tremendous to have that done. Enclosure guy won't get final measurements 'till the pavers are installed on his footers. Don't blame him but that puts the enclosure on day-for-day delay.

Chris

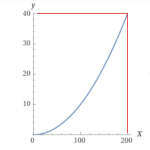

(2) 2.5" returns at 200 feet will be approximately this.

www.wolframalpha.com

www.wolframalpha.com

y=0.001(X/2)^2, y from 0 to 20 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

- May 3, 2007

- 18,088

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I thought you said there were four floor returns for the IE pump? What is the internal diameter of those 4 pipes?Yes that's right sorry. The returns go to the four floor returns in front of the wall or to return to the pool wall plus one to the spa or three small returns to the bubblers on the sun deck.

The spa and normal pool returns are not relevant as they are on a separate loop.

The original drawing does not show these floor returns:

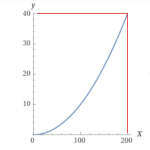

If you had one 2.5" return at 200 feet, it would be approximately this.

You would have 4 times as much head loss.

www.wolframalpha.com

www.wolframalpha.com

You would have 4 times as much head loss.

y=0.001(X)^2, y from 0 to 40 - Wolfram|Alpha

Wolfram|Alpha brings expert-level knowledge and capabilities to the broadest possible range of people—spanning all professions and education levels.

- May 3, 2007

- 18,088

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

I probably would not have had the returns coming in vertically.

I probably would have had them come in horizontally to help provide floor cleaning as well as not creating a weird effect at the water surface.

I would remove any fittings in the returns.

You probably could have used channel drains as returns.

www.troublefreepool.com

www.troublefreepool.com

I probably would have had them come in horizontally to help provide floor cleaning as well as not creating a weird effect at the water surface.

I would remove any fittings in the returns.

You probably could have used channel drains as returns.

Channel Drains as Returns for Infinity/Negative Edge Pools

As long as they meet the GPM requirement for the system, has anyone used channel drains, specifically Paramount Buzztop drains, as returns? My PB has used these in the past as side wall returns but I've been advised to ensure the manufacturer (Paramount) approves these as suctions. I have not...

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.