- May 3, 2025

- 8

- Pool Size

- 20000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool Core-55

I have a Pentair MasterTemp 250 LP and I am having a Ignition Error when trying to turn the heater on the pool. I have had the heater going on four years, it worked fine last year and once

I opened the Pool this year it worked one or two days and now it will not stay on. I have troubleshot just about everything I have read that can give you and ignition error. When I turn the heater on the blower comes on, and then you hear a click and the rumbling sound of the igniter igniting the gas. Heat comes out of the exhaust for about 5 seconds and then shuts off, the heater cycles this like three times and then quits and shows the error code.

1. I checked my propane level in the tank and it is at 40%.

2. I replaced the air flow switch.

3. I replaced the ignition control switch.

4. I bypassed the AGS and high limit switch with a jumper and still got the error.

5. I checked the igniter with my ohm meter and it read at 96ohms so it is still good.

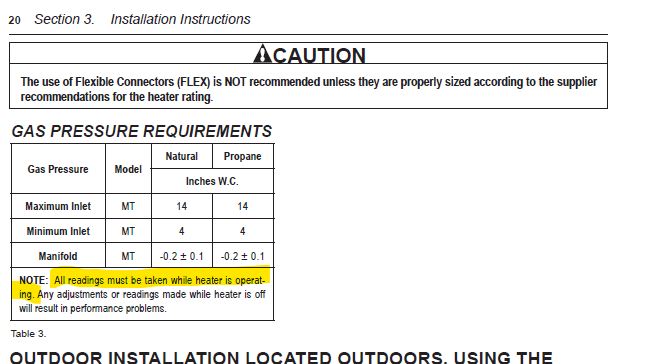

6. I tested the gas pressure coming into the inlet side of the gas control valve with an analog manometer. It started off at about 10in./wc before I turned the heater on, when the heater lights it drops to about 4 in./wc and when the heater shuts off the pressure goes up to about 15 in./wc. Then the heater will try to light again and it will drop to about 4 in./wc . I read its not suppose to drop more than 2 or 3 in./wc when it lights but it still should stay on right, just burn rich.

6. I tested the gas pressure on the manifold side(see video) below it does not drop to a negative reading when it fires up.

Any help with this would be greatly appreciated.

I opened the Pool this year it worked one or two days and now it will not stay on. I have troubleshot just about everything I have read that can give you and ignition error. When I turn the heater on the blower comes on, and then you hear a click and the rumbling sound of the igniter igniting the gas. Heat comes out of the exhaust for about 5 seconds and then shuts off, the heater cycles this like three times and then quits and shows the error code.

1. I checked my propane level in the tank and it is at 40%.

2. I replaced the air flow switch.

3. I replaced the ignition control switch.

4. I bypassed the AGS and high limit switch with a jumper and still got the error.

5. I checked the igniter with my ohm meter and it read at 96ohms so it is still good.

6. I tested the gas pressure coming into the inlet side of the gas control valve with an analog manometer. It started off at about 10in./wc before I turned the heater on, when the heater lights it drops to about 4 in./wc and when the heater shuts off the pressure goes up to about 15 in./wc. Then the heater will try to light again and it will drop to about 4 in./wc . I read its not suppose to drop more than 2 or 3 in./wc when it lights but it still should stay on right, just burn rich.

6. I tested the gas pressure on the manifold side(see video) below it does not drop to a negative reading when it fires up.

Last edited: