Hello,

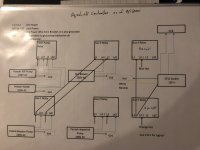

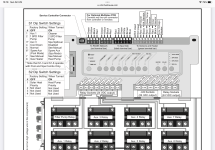

I have Jandy RS6 Automation system with a single speed HP 2.0 pump running a pool/spa combo with an old hayward Northstar pump. This controls the pool and spa control, blower control, spa and pool light control. See pics. I want to change my pool pump to variable speed pump using the Intelliflo3 VSF (011075 or 011076). I am aware that my automation system is dated and I want to make sure that I have everything I need to make my pool and spa work with all current functions listed above. I currently have a PDA inside my house and I control my pool/spa functions through this and I also program it through the PDA. I like the idea of having controls on my phone or computer and want to upgrade if costs reasonable. I did some research about methods of upgrading my current system. I saw the older IQ9000 and the newer IQ30-RS ($1000) Upgrade which I read will work on my dated system, but not sure if intellioflo3 will work.

I would like to connect my variable speed pump (intellioflo3 VSF 3HP with possible. I/O board) and be able to control the pool, spa, blower, pool and spa lights and new VS pump speed.

Can I do that with my current configuration? Do I need to upgrade to IQ30-RS to do that? The pool company I contacted told me I need to get an intellicenter control to work an intelliflo pump but this is an expensive route. I ready otherwise. I want to be sure the system will work before i purchase parts. i would like to do this DIY if possible. Please if you have any advise as to where I can get required parts cheaper, please let me know.

Thanks in advance for your input and recommendations.

Patrick

I have Jandy RS6 Automation system with a single speed HP 2.0 pump running a pool/spa combo with an old hayward Northstar pump. This controls the pool and spa control, blower control, spa and pool light control. See pics. I want to change my pool pump to variable speed pump using the Intelliflo3 VSF (011075 or 011076). I am aware that my automation system is dated and I want to make sure that I have everything I need to make my pool and spa work with all current functions listed above. I currently have a PDA inside my house and I control my pool/spa functions through this and I also program it through the PDA. I like the idea of having controls on my phone or computer and want to upgrade if costs reasonable. I did some research about methods of upgrading my current system. I saw the older IQ9000 and the newer IQ30-RS ($1000) Upgrade which I read will work on my dated system, but not sure if intellioflo3 will work.

I would like to connect my variable speed pump (intellioflo3 VSF 3HP with possible. I/O board) and be able to control the pool, spa, blower, pool and spa lights and new VS pump speed.

Can I do that with my current configuration? Do I need to upgrade to IQ30-RS to do that? The pool company I contacted told me I need to get an intellicenter control to work an intelliflo pump but this is an expensive route. I ready otherwise. I want to be sure the system will work before i purchase parts. i would like to do this DIY if possible. Please if you have any advise as to where I can get required parts cheaper, please let me know.

Thanks in advance for your input and recommendations.

Patrick