- Sep 24, 2022

- 17

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Plumber was coming today to plumb in a heater bypass for my new construction so I left him a Jandy 3 way valve and check valve. Plumbing has been done for a while so this was an addition/change I wanted.

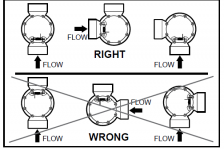

Anyway, he didn’t use the check valve. There was already a check valve before the SWG that you will see in the attached picture. Now I’m no plumber, but I assume there should be another one off the heater before the Tee fitting they put in today. The way I see it, in bypass mode, water will be able to go into the heater outlet. Unless there’s a check valve in the heater at the outlet to not allow this.

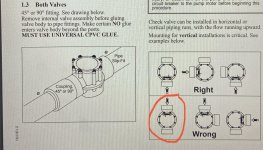

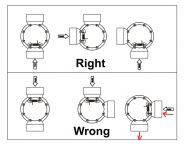

I gave my pool guy this diagram from here that also shows a check valve. Here is the plumbing.

Is this ok, or am I correct to tell them to fix it?

Thanks in advance

Anyway, he didn’t use the check valve. There was already a check valve before the SWG that you will see in the attached picture. Now I’m no plumber, but I assume there should be another one off the heater before the Tee fitting they put in today. The way I see it, in bypass mode, water will be able to go into the heater outlet. Unless there’s a check valve in the heater at the outlet to not allow this.

I gave my pool guy this diagram from here that also shows a check valve. Here is the plumbing.

Is this ok, or am I correct to tell them to fix it?

Thanks in advance