- May 1, 2019

- 47

- Pool Size

- 17000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45

I'm thinking about installing a saltwater chlorine generator and trying to plan it out with my current setup. I'm comfortable doing some PVC cutting and cementing, but need some guidance on how to work with what is already there - I'm not familiar enough with all the various PVC connection types to know what is reusable, what can be cut out, etc.

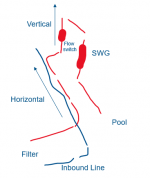

Side view for context. You can see my return coming from the filter going down to the chlorinator in the center.

This is the top view, and how I think the return line should be reworked to allow for the SWCG. The green outline represents the proposed return line. Instead of taking a right angle down, it would stay at the same vertical level and run directly below the existing intake line. It would not go down vertically until the end where it runs into the ground.

1) Does that seem like a reasonable plan?

2) The part that connects to the multi-port valve (circled in red) - how will I connect new pipe in there? It looks like the piece on the left is threaded into the valve. Do I just cut that vertical pipe, unscrew the threaded part with elbow attached, and buy a new threaded part to connect into the valve?

3) Where should I cut to connect into the pipe in the ground? It looks like there is some type of coupling right at ground level - do I cut below that?

Bonus - I would prefer to keep the tab chlorinator in the setup if it isn't too big of a deal. Was thinking it would be raised up, added in line right after the SWCG. But it really looks like that 90 degree elbow is permanently glued into it, which will make it harder to keep.

Any guidance would be greatly appreciated.

Side view for context. You can see my return coming from the filter going down to the chlorinator in the center.

This is the top view, and how I think the return line should be reworked to allow for the SWCG. The green outline represents the proposed return line. Instead of taking a right angle down, it would stay at the same vertical level and run directly below the existing intake line. It would not go down vertically until the end where it runs into the ground.

1) Does that seem like a reasonable plan?

2) The part that connects to the multi-port valve (circled in red) - how will I connect new pipe in there? It looks like the piece on the left is threaded into the valve. Do I just cut that vertical pipe, unscrew the threaded part with elbow attached, and buy a new threaded part to connect into the valve?

3) Where should I cut to connect into the pipe in the ground? It looks like there is some type of coupling right at ground level - do I cut below that?

Bonus - I would prefer to keep the tab chlorinator in the setup if it isn't too big of a deal. Was thinking it would be raised up, added in line right after the SWCG. But it really looks like that 90 degree elbow is permanently glued into it, which will make it harder to keep.

Any guidance would be greatly appreciated.