Hi All,

I want to prevent my Stenner pump (for MA) from ever running when there is no flow. I read this thread but I want to do it differently if possible and hopefully simpler.

www.troublefreepool.com

www.troublefreepool.com

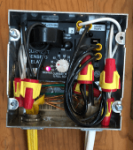

I am thinking of using a relay to open/close the outlet's cricuit where the pump is plugged. I found this particular relay which powers itself from the 110 V side to the 24v input. (Based on the single review, seems to be the way I would need it to open/close):

www.zoro.com

www.zoro.com

This would be the flow switch (same as in the above thread):

Did anyone attempt to do it this way? Or is there a simpler way?

Any guidance is appreciated.

Allen

I want to prevent my Stenner pump (for MA) from ever running when there is no flow. I read this thread but I want to do it differently if possible and hopefully simpler.

Controlling Stenner with a Flow Switch?

I have a Stenner Econ T for Chlorine injection that I want to control with a flow switch. i am concidering using the following switch: https://www.amazon.com/gp/product/B01MR8371I/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 but I haven’t been able to locate any specs on the switch. The Stenner...

I am thinking of using a relay to open/close the outlet's cricuit where the pump is plugged. I found this particular relay which powers itself from the 110 V side to the 24v input. (Based on the single review, seems to be the way I would need it to open/close):

Functional Devices Inc / Rib CLC212 $26.39 Closet Light Controller, Door, Gray, 120VAC | Zoro.com

Order Functional Devices Inc / Rib Closet Light Controller, Door, Gray, 120VAC, CLC212 at Zoro.com. Great prices & free shipping on orders over $50 when you sign in or sign up for an account.

This would be the flow switch (same as in the above thread):

Amazon.com: BLUE WORKS Flow Switch Compatible with Hayward Goldline Systems, Flow Sensor with Tee: Garden & Outdoor

Amazon.com: BLUE WORKS Flow Switch Compatible with Hayward Goldline Systems, Flow Sensor with Tee: Garden & Outdoor

www.amazon.com

Did anyone attempt to do it this way? Or is there a simpler way?

Any guidance is appreciated.

Allen