Setup Overview:

I have an 18x36 ft pool and an 8x8 spillover hot tub being installed in northern NJ. The system is new. I’ve attached lots of photos.

Equipment List:

I have an 18x36 ft pool and an 8x8 spillover hot tub being installed in northern NJ. The system is new. I’ve attached lots of photos.

Equipment List:

- Pump: Pentair IntelliFlo3 VSF (variable speed, set to run pool mode 8 AM–8 PM & spa mode 2 PM–3 PM daily)

- Chlorine Generator: Pentair IntelliChlor IC40 (set to 55% output)

- Valve Actuator: (2) Pentair IntelliValve Valve Actuator (model 521485) to control flow between pool and hot tub

- Automation System: Pentair IntelliCenter (with High-Power Wireless Link Kit, part number 523418, for Wi-Fi connectivity)

- Heater: Pentair MasterTemp 400 (recently installed gas heater)

- Pool and hot tub were filled by water tankers. Salt was added, followed by “Shock-It” treatment, and the IntelliChlor was set to 55% shortly after.

- Installed the IntelliValve to manage flow between pool and hot tub. Initially, one valve always returned to position 0 (even after saving at 24), but resolved with a workaround (saved 0 as home, 24 as secondary). Not sure why this was needed.

- Installed the Wi-Fi module for the IntelliCenter to enable remote control via the Pentair Home app.

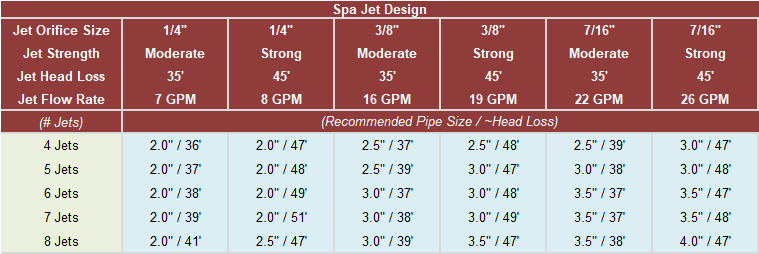

- Noticed the hot tub jets have low pressure when the air bubbler is off, feeling much weaker than expected.

- The hot tub uses Waterway Poly Jet housings with Twist-Lock jet inserts (pushed in, twisted to lock). Some inserts twist easily to open/close or adjust flow, but others are very stiff and barely move. The builder applied liquid Teflon to the housing threads (for lock nuts, not inserts).

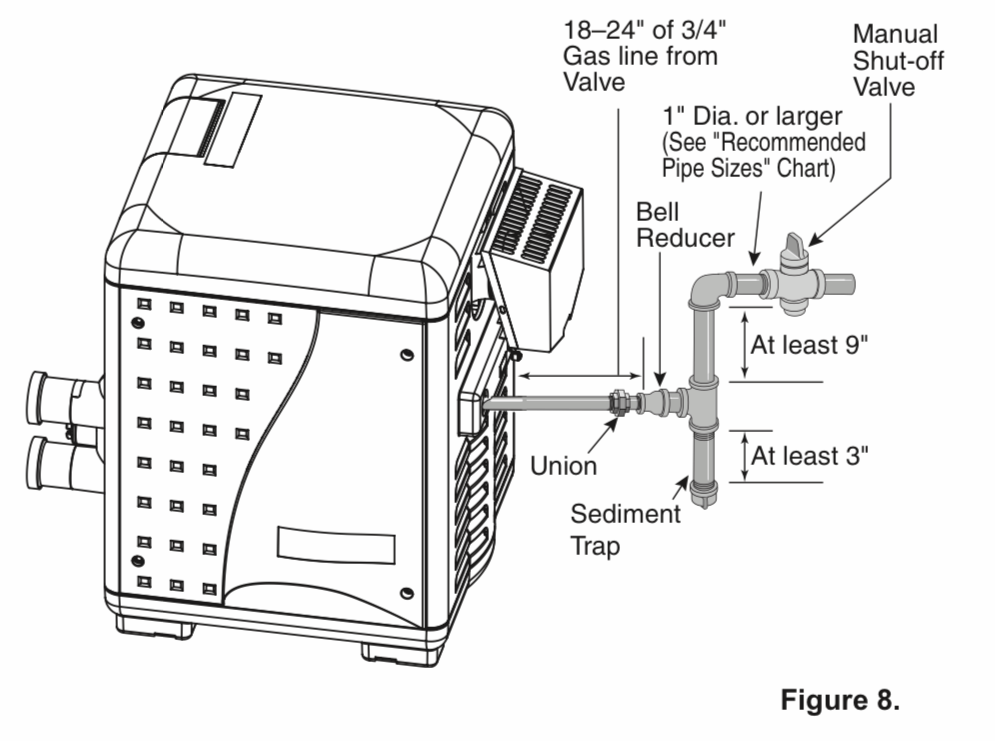

- Installed the Pentair MasterTemp 400 heater, but it makes a whistling noise and cuts off before reaching the desired spa temperature. Scheduled PSEG to upgrade the gas meter, as I was advised it might be too small.

- Hot Tub Jets Losing Pressure: When the air bubbler is off, the hot tub jets have very low pressure. The pump speed stays at ~3450 RPM, but the water flow feels weak without air. Is this normal due to the Venturi effect, or could it be a flow issue? Might the IntelliValve position, pump settings, or plumbing be affecting this?

- Stiff Hot Tub Jet Inserts: Some Waterway Poly Jet Twist-Lock inserts are very hard to twist (for opening/closing or flow adjustment), while others move easily. The builder used liquid Teflon on the housing threads. Could overtightening (due to Teflon) or residue in the Twist-Lock grooves cause this?

- Heater Issues: The MasterTemp 400 makes a whistling noise and cuts off before reaching the desired spa temperature. Could this be due to insufficient flow (related to jet issues), gas pressure, or a heater problem? PSEG is upgrading the gas meter, but any other ideas?

- General Equipment Check: Is my setup appropriate for an 18x36 pool and 8x8 spillover hot tub? Equipment:

- IntelliFlo3 VSF pump

- IntelliChlor IC40 (55% output)

- IntelliValve for flow control

- IntelliCenter with Wi-Fi

- MasterTemp 400 heater