Exhaust Gas Temperature

While running, press and hold the On button to display the exhaust temperature (Older Models).

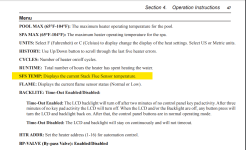

The new models use the Menu to get the SFS.

Here is what the normal exhaust temperature should be:

- Below 250 degrees...very low

- 250 to 290 ..................low

- 290 to 350.................acceptable

- 350 to 480 ..................high

- Above 480...................error/shutdown.

Note: HD models can be up to 75 degrees higher. HD models use a cupro nickel exchanger, and the efficiency is slightly lower, resulting in less heat transfer and more waste heat.

If the exhaust gas temperature is higher than normal, water may bypass the heat exchanger through a broken bypass valve.

If you hold down the "pool on" button, it stays on 80, then flashes to 40, then back to 80, then the 80/40 reading and E05 indicate that the board is not getting a reading from the sensor. It's usually a bad sensor or damaged wires.

www.troublefreepool.com

111 C is 232 F, which is low, but check the stack flue temperature from the control panel.

Heaters can have a smell on first startup.

For the venting, I would have to refer you to a qualified gas contractor as I do not know enough to give you a good answer.

Adding a Carbon Monoxide Detector might be a good idea to detect carbon monoxide at dangerous levels.

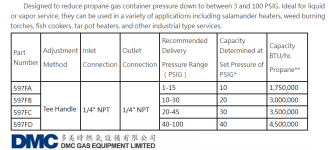

The 597FA regulator seems to be designed for Propane.

Is your heater Natural Gas or Propane?

Description: 597FA HP REGULATOR 3-15 PSIG-1/4 FNPT X 1/4 FNPT

Features / Benefits

Designed to reduce propane gas container pressure down to between 3 and 100 PSIG.

597FA HP REGULATOR 3-15 PSIG-1/4 FNPT X 1/4 FNPT

www.gasequipment.com

View attachment 622157

RegO High Pressure Regulator 597F designed to reduce propane gas container pressure down to between 3 and 100 PSIG. Ideal for liquid or vapor service, they can be used in a variety of applications including salamander heaters, weed burning torches, fish cookers, tar pot heaters, and other...

dmc-gas.com

View attachment 622156

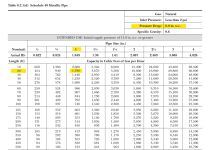

The 6" might be due to the wrong regulator or undersized pipe.

What is the heater BTU/Hr, Pipe Size and Pipe length?