Once the blower pressure switch is closed, you should get

24 volts AC from TH to Ground, which is what closes the relay that powers the ignitor.

L1 closes to S1 and L2 closes to S2.

If the power supply is 240 VAC, the Fenwal ICM has to convert the 240 volts to 120, so L1 cannot close directly to the (240) S1.

On a call for heat, the blower and HSI (Hot Surface Ignitor) are energized.

The HSI should receive 120 volts when you hear the blower start.

If the main supply voltage going to the heater is 120 volts, then the voltage reading to the HSI should be a clean 120 volts.

If the power to the heater is 240 volts, the voltage sent to the HSI is an intermittent pulse that "simulates" 120 volts.

The intermittent pulse will not read as a clean voltage by a multimeter.

A true RMS will get a better read on the voltage, but the voltage might read higher or lower than exactly 120 volts.

In about 20 seconds, the gas valve opens and ignition should occur.

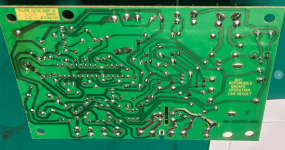

View attachment 621866

If your heater is correctly connected to 240 Volts AC, the Ignition Control Module (ICM) will convert the 240VAC to an intermittent pulse to the ignitor.

Digital meters don’t read this type of signal well.

(An analog meter will give a better reading than a digital meter).

If the ICM is bad, your voltmeter will read either 0 VAC or 240 VAC.

If your ICM is good, your meter will read some voltage between 0 and 240 VAC.

Exactly what reading you get will depend on the meter, but with a good ICM, the reading won’t be 0 VAC or 240 VAC, but somewhere in between.

View attachment 621868