Hello,

I had contacted the local gas company (gas provider), two qualified gas plumbers and local officials who authorize gas installations in my area. It took me long time in order to get the required inspections and quotations.

In summary,

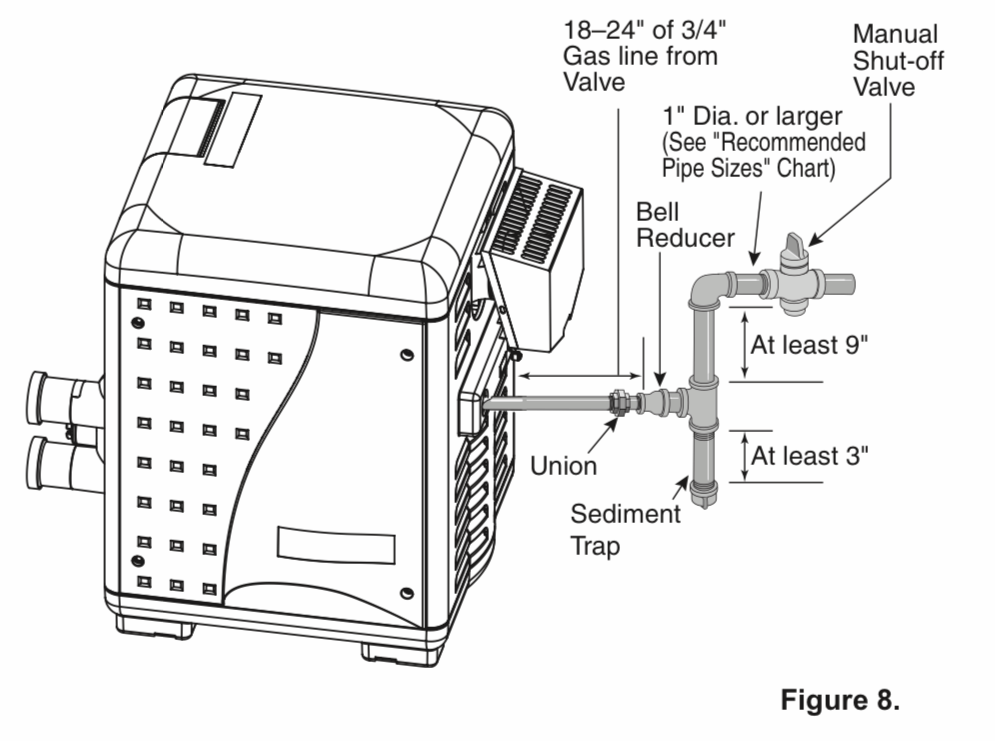

Based in previous experience (where the gas line was installed incorrectly), @JoyfulNoise, @JamesW, please, may you take a look to this diagram and let me know if there are something incorrect from your point of view.

Additionally, any thoughts or suggestions regarding which pressures must be set in each valve?

Thanks again!

----

References:

I had contacted the local gas company (gas provider), two qualified gas plumbers and local officials who authorize gas installations in my area. It took me long time in order to get the required inspections and quotations.

In summary,

- The local gas company will perform the modifications at the meter side, including the supply of the meter and regulators

- The qualified gas plumber will perform the modifications at the heater side, including the installation of the regulator, valves, sediment (trap), etc... The regulator at the heater must be placed outside the service room as required by the officials

- The pipe length is around:

- High pressure: 68.5m (225ft)

- Low pressure: 6.3m (20ft)

Based in previous experience (where the gas line was installed incorrectly), @JoyfulNoise, @JamesW, please, may you take a look to this diagram and let me know if there are something incorrect from your point of view.

Additionally, any thoughts or suggestions regarding which pressures must be set in each valve?

Thanks again!

----

References: