New pool owner here. We opened our pool around May of this year. Unfortunately, I was very poorly educated prior to the build. I didn't understand SWGs, automation, and the like. Our builder, as a result of my ignorance, built am a very nice basic pool. Not his fault at all. After a few months on TFP and a summer of education on TFP and adding chlorine, I realize I probably would like an SWG system, and I might as well upgrade to automation at the same time. My builder is capable of the install, and indicated he would sell equipment at his cost, but he is unable to "educate me regarding options and possibilities" due to language limitations between us! He is a great guy, but his English is limited and my Spanish is nonexistant. I have an Intelliflow VS pump and Jandy lights with no automation. I am running the pump per internal programming. We are not heavy pool users, but thought that if I am upgrading, I should at least plan for future possibilities. I may as well plan for App controlled spa and temperature management at this time. I assume automated valves would be needed for app control. Is the Intellicenter and Pentair SWG most appropriate? I'd appreciate thoughts and input.

Looking to upgrade to Intellicenter and SWG,

- Thread starter mriddell

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Confirm you have a spa?

Post pictures of your equipment pad.

You want the IntelliCenter bundle that includes the IntelliCenter, SWG, two actuators, and wireless link...

www.troublefreepool.com

www.troublefreepool.com

Post pictures of your equipment pad.

You want the IntelliCenter bundle that includes the IntelliCenter, SWG, two actuators, and wireless link...

Pentair Automation Systems - Further Reading

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I would remove this CB panel and replace it with the IntelliCenter Load Center. All the CB's will go in the Load Center.

You will need to rewire the light switches next to it into the IntelliCenter panel.

Good you are getting the SWG as that tablet chlorinator will kill your expensive MasterTemp heater even with the check valve there.

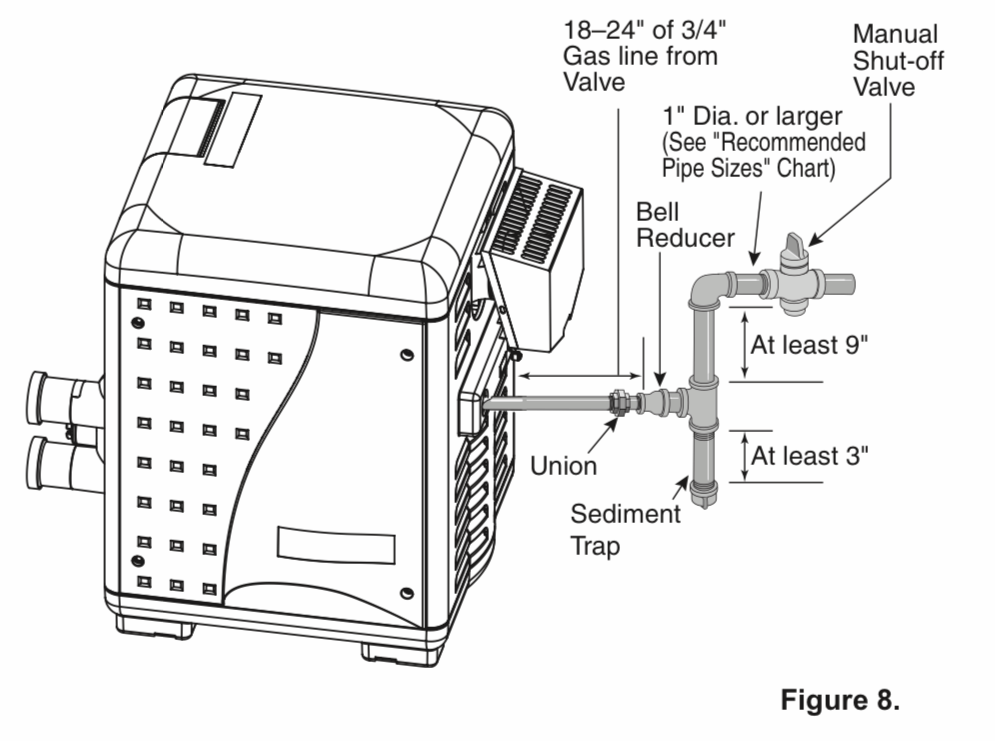

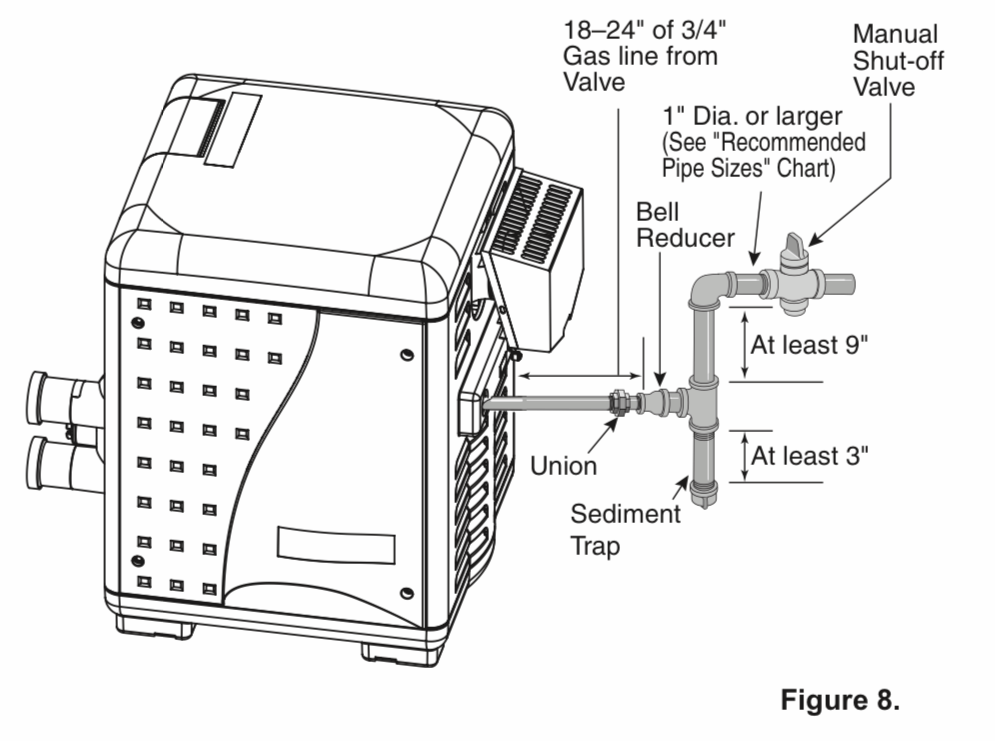

Your heater gas line going into the heater is not correct. The correct sediment trap design is for the gas to make a 90 degree turn to go into the heater while the sediment can drop down into the sediment traps as shown in the Pentair diagram below. Your sediment will not necessarily make the 90 degree bend into the trap and more likley go into the gas valve and clog it.

www.troublefreepool.com

www.troublefreepool.com

You will need to rewire the light switches next to it into the IntelliCenter panel.

Good you are getting the SWG as that tablet chlorinator will kill your expensive MasterTemp heater even with the check valve there.

Your heater gas line going into the heater is not correct. The correct sediment trap design is for the gas to make a 90 degree turn to go into the heater while the sediment can drop down into the sediment traps as shown in the Pentair diagram below. Your sediment will not necessarily make the 90 degree bend into the trap and more likley go into the gas valve and clog it.

Heater Maintenance - Further Reading

We built and opened our pool this past May. First pool built. I was a complete newbie, uneducated, and unaware of what I wanted or needed. My builder is a great guy, gave us a good price and completed the job to my satisfaction at the time. We however, were significantly impacted by a language barrier. He did his best to understand my thinking and gave me what he thought I wanted. Totally MY fault for not understanding the planned build, available options, and what I actually wanted. I was poorly educated as to what I wanted, current equipment, and what I was getting. Again, my fault, and water under the bridge. Wish I had found TFP about a year ago!!!

Multiple pictures are included. Basically, I have no automation. I decided I wanted to upgrade to a salt system, and as a result, decided to go ahead with an Intellicenter panel. I got information regarding what I needed on TFP... thanks guys, and after discussing with the contractor, bought the equipment, as the TFP suggested site was much cheaper than what he could have bought the equipment for. I got the IC40 Personality pack with the Intellicenter, IC40, and 2 Intellivalves.

Now, it looks like I'm on my on. The contractor initially said he'd do the conversion, but then said he wanted to sub it to another contractor he uses for automation. I got that service's info and contacted them. Came over promptly, said he'd take care of it, and get back to me the following week. No word. After several days, I contacted him. Said he would be there "that Saturday or the following Monday." Never came. Now will not answer or return calls! I called another service. They came out and said they subbed this work to another builder, who also came by, looked at the equipment, took pics of the panel, and said he would get back to me. I texted my email address to him as requested, and he replied that he would get back with a quote within 48 hrs.... 6-8 days ago. Suspect this job is just too small for anyone to bother with it. Don't know... maybe I have bad breath! We haven't even talked price.

I'm kinda handy, retired, and have lots of time. I'm tired of being given the cold shoulder. I think I'll have an electrician hang the panel and assist with the hot wiring needed, then finish with the valves, heater connection to the IC, and miscellaneous myself. Can I get some close observation and a second set of eyes?

Here is what I have:

I have a 70 amp breaker coming to the sub panel. Hope not to change that. There is also another 20 amp single pole CB in the outside panel that might be coming to the sub panel. I won't know until we open the sub panel up. You can see the sub panel as it is now. CBs are Siemens or Eaton, both approved on the Intellicenter cover. I did not check the part numbers, but plan to. No Pentair breakers, but I've not had issues with CBs popping, so, plan to leave well enough alone. The two rigid conduits are for a switch going to lights and blower closer to the spa that I won't need (left side of sub panel), and the main wiring coming into the center. I think I can set the IC panel to accommodate the existing conduit in the center. The remining flexible conduit will be handy and not really an issue.

Planned setup: Relays:

1. Pump: current breaker wired CB to LOAD side, Pump wired to LINE. Will wire the SWG for 240, on the load side.

2. Polaris boost pump: Uncertain. CB to LINE, Polaris to LOAD?

3. Jandy blower: 240, Same as #2?

4. Mastertemp 400 NG: 240, Same as #2?

5. Lights. They are 120V. Relay post 1 and 2?

6. 120 CB for IC transformer

Does the above plan for relay wiring make sense? Will the Jandy blower, boost pump, and light box work in this configuration? I assume I'll have to identify them in the IC web interface. Correct?

My intent is the move the backflow valve closer to the heater and put the IC40 in front of the clorinator. Don't see any reason to remove the chlorinator, though I don't plan at present to use it.

Thoughts? Thanks in advance.

Multiple pictures are included. Basically, I have no automation. I decided I wanted to upgrade to a salt system, and as a result, decided to go ahead with an Intellicenter panel. I got information regarding what I needed on TFP... thanks guys, and after discussing with the contractor, bought the equipment, as the TFP suggested site was much cheaper than what he could have bought the equipment for. I got the IC40 Personality pack with the Intellicenter, IC40, and 2 Intellivalves.

Now, it looks like I'm on my on. The contractor initially said he'd do the conversion, but then said he wanted to sub it to another contractor he uses for automation. I got that service's info and contacted them. Came over promptly, said he'd take care of it, and get back to me the following week. No word. After several days, I contacted him. Said he would be there "that Saturday or the following Monday." Never came. Now will not answer or return calls! I called another service. They came out and said they subbed this work to another builder, who also came by, looked at the equipment, took pics of the panel, and said he would get back to me. I texted my email address to him as requested, and he replied that he would get back with a quote within 48 hrs.... 6-8 days ago. Suspect this job is just too small for anyone to bother with it. Don't know... maybe I have bad breath! We haven't even talked price.

I'm kinda handy, retired, and have lots of time. I'm tired of being given the cold shoulder. I think I'll have an electrician hang the panel and assist with the hot wiring needed, then finish with the valves, heater connection to the IC, and miscellaneous myself. Can I get some close observation and a second set of eyes?

Here is what I have:

I have a 70 amp breaker coming to the sub panel. Hope not to change that. There is also another 20 amp single pole CB in the outside panel that might be coming to the sub panel. I won't know until we open the sub panel up. You can see the sub panel as it is now. CBs are Siemens or Eaton, both approved on the Intellicenter cover. I did not check the part numbers, but plan to. No Pentair breakers, but I've not had issues with CBs popping, so, plan to leave well enough alone. The two rigid conduits are for a switch going to lights and blower closer to the spa that I won't need (left side of sub panel), and the main wiring coming into the center. I think I can set the IC panel to accommodate the existing conduit in the center. The remining flexible conduit will be handy and not really an issue.

Planned setup: Relays:

1. Pump: current breaker wired CB to LOAD side, Pump wired to LINE. Will wire the SWG for 240, on the load side.

2. Polaris boost pump: Uncertain. CB to LINE, Polaris to LOAD?

3. Jandy blower: 240, Same as #2?

4. Mastertemp 400 NG: 240, Same as #2?

5. Lights. They are 120V. Relay post 1 and 2?

6. 120 CB for IC transformer

Does the above plan for relay wiring make sense? Will the Jandy blower, boost pump, and light box work in this configuration? I assume I'll have to identify them in the IC web interface. Correct?

My intent is the move the backflow valve closer to the heater and put the IC40 in front of the clorinator. Don't see any reason to remove the chlorinator, though I don't plan at present to use it.

Thoughts? Thanks in advance.

Attachments

-

![IMG_4066[1].jpg](/data/attachments/328/328174-75171e1510f38c0e80fddb8572a05f79.jpg) IMG_4066[1].jpg634.4 KB · Views: 6

IMG_4066[1].jpg634.4 KB · Views: 6 -

![IMG_4065[1].jpg](/data/attachments/328/328173-2f3218995a3741874a02671f04c90e11.jpg) IMG_4065[1].jpg712.6 KB · Views: 6

IMG_4065[1].jpg712.6 KB · Views: 6 -

![IMG_4064[1].jpg](/data/attachments/328/328172-018c664179724272370f3c4d05591737.jpg) IMG_4064[1].jpg524.4 KB · Views: 9

IMG_4064[1].jpg524.4 KB · Views: 9 -

![IMG_4063[1].jpg](/data/attachments/328/328171-50302738dcc66728bcbb38395c0a41c2.jpg) IMG_4063[1].jpg377.8 KB · Views: 9

IMG_4063[1].jpg377.8 KB · Views: 9 -

![IMG_4062[1].jpg](/data/attachments/328/328170-ea197fd443eb28e0004541ac3e9eab43.jpg) IMG_4062[1].jpg325.9 KB · Views: 9

IMG_4062[1].jpg325.9 KB · Views: 9 -

![IMG_4061[1].jpg](/data/attachments/328/328169-349da4f08bff990f88a9f5122b3058f9.jpg) IMG_4061[1].jpg290.2 KB · Views: 7

IMG_4061[1].jpg290.2 KB · Views: 7 -

![IMG_4058[1].jpg](/data/attachments/328/328168-93212b551ba1769c526de01c8f018d11.jpg) IMG_4058[1].jpg325.3 KB · Views: 7

IMG_4058[1].jpg325.3 KB · Views: 7 -

![IMG_4057[1].jpg](/data/attachments/328/328167-2c78e7b481a7f10b5c72ea3e7b3add3f.jpg) IMG_4057[1].jpg338.3 KB · Views: 7

IMG_4057[1].jpg338.3 KB · Views: 7 -

![IMG_4067[1].jpg](/data/attachments/328/328175-5ec6ec4311ad1122b398bf99d011da86.jpg) IMG_4067[1].jpg695.2 KB · Views: 7

IMG_4067[1].jpg695.2 KB · Views: 7

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Replace your CB panel with the IntelliCenter panel.

You have no GFCI CBs which code requires. You should get GFCI CB for the IntelliFlo pump, cleaner pump, and heater. Get Pentair or Seimans GFCI CB.

You can power the cleaner pump and heater from the same CB.

You should install a Heater Bypass - Further Reading when you remove the tab chlorinator and install the IntelliChlor cell.

Does your heater have a 5 button or 6 button control panel?

You have no GFCI CBs which code requires. You should get GFCI CB for the IntelliFlo pump, cleaner pump, and heater. Get Pentair or Seimans GFCI CB.

You can power the cleaner pump and heater from the same CB.

You should install a Heater Bypass - Further Reading when you remove the tab chlorinator and install the IntelliChlor cell.

Does your heater have a 5 button or 6 button control panel?

So, I'll plan on getting the new CBs and plan for a heater bypass. Were the wiring of the AUX and PUMP relays correct otherwise? Also, is there any benefit to controlling the heater via the Com port? I see that now in the heater install info. I have read lots of threads here indicating that it was not available, but none posted recently. My heater is a 2024 model. Again, not sure if available. Heater does have 6 buttons. And, thanks for your help thus far!

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Relays:

- Filter Pump - GFCI 240V 20A CB to LINE; Intelliflo pump to LINE; SWG transformer to LOAD

- AUX1 - GFCI 240V 20A CB to LINE; heater to LINE; Polaris cleaner to LOAD

- AUX2 -240V 20A CB to LINE; Spa blower to LOAD

- AUX3 - GFCI 120V 20A CB to LINE; Light to LOAD - unless you wire light through GFCI outlet on lower right side

- 120V 15A CB - Intellicenter transformer

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Connecting heater control using RS-485 will send heater status and error messages to IntelliCenter. When using the RS485 comms, adjusting the set point adjusts the IntelliCenter and the MasterTemp heater set points simultaneously. No more needing to verify the heater set point has not been altered and is above the IntelliCenter set pointAlso, is there any benefit to controlling the heater via the Com port?

Read Pentair MasterTemp Heaters - Further Reading

Circuit breakers: These OK?

|

RS-485. I have one port taken with the SWG, another with the pump. Would you pigtail the pump and heater to use the RS-485 connection?

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

You need two 240V 20 A GFCI and one non-GFCI.Circuit breakers: These OK?

Siemens 20 Amp 1-Pole Type QPF2 GFCI Circuit Breaker Store SKU #992620 Internet #206965288 2 x $54.98

Siemens QPFB 20 Amp 2-Pole GFCI Circuit Breaker Store SKU #1011964515 Internet #330823529 3 x $119.00

You need one 120V GFCI for the light and one non-GFCI for the IntelliCenter power.

Those CBs are fine for the GFCI CBs.

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

RS-485. I have one port taken with the SWG, another with the pump. Would you pigtail the pump and heater to use the RS-485 connection?

You have two more available RS-485 COMM connectors on the surge card on the back of the panel.

You can put two wires under each RS-485 screw although it is not necessary for your setup. You have enough COMM connectors for your devices.

Thanks, aj. When setting up the intellivalves for return and intake, I assume the green and yellow wires are also placed in a com port? If so, shall I twist them together and utilize a single port, say on the surge board on the back? Regarding the heater bypass, would a "regular" valve be sufficient, or should I use an Intellivalve? Com port use now for the SWG, heater, and pump. Adding three valves is going to make for lots of possibilities for poor wire connections.

And thanks again so much for all your hand holding. I really appreciate it. Most of this stuff is becoming more obvious as I read manuals and study TFP, but having someone to look over my shoulder is invaluable!

And thanks again so much for all your hand holding. I really appreciate it. Most of this stuff is becoming more obvious as I read manuals and study TFP, but having someone to look over my shoulder is invaluable!

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

When setting up the intellivalves for return and intake, I assume the green and yellow wires are also placed in a com port?

The IntelliValves are not Intelli. They are as dumb as regular actuators. Leave the green and yellow wires wrapped and not connected. It is doubtful Pentair will make valves in the field Intelli if they ever get it working.

Regarding the heater bypass, would a "regular" valve be sufficient, or should I use an Intellivalve?

Regular diverter valve with a standard actuator is preferred. They have the handle on it and lets you see the position of the valve in a glance.

Com port use now for the SWG, heater, and pump. Adding three valves is going to make for lots of possibilities for poor wire connections.

No valve actuators are connected to RS-485.

Welcome!And thanks again so much for all your hand holding. I really appreciate it. Most of this stuff is becoming more obvious as I read manuals and study TFP, but having someone to look over my shoulder is invaluable!

A thought. I'm ready to wire the panel now. The Polaris sweep, according to my understanding, needs the pool pump running when it is used. Is it reasonable then to wire it to the pump relay on the load side as opposed to wiring it independent of the pump? Or should this be covered in a routine?

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The IntelliCenter handles that.A thought. I'm ready to wire the panel now. The Polaris sweep, according to my understanding, needs the pool pump running when it is used. Is it reasonable then to wire it to the pump relay on the load side as opposed to wiring it independent of the pump? Or should this be covered in a routine?

You label the cleaner circuit type as Master Cleaner and it will only run that circuit when the filter pump is on.

Just wire the booster pump to its own CB and relay.

- Jul 21, 2013

- 65,101

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Sooo... this thing is smarter than I thought!