Hi all -

I am replacing my Hayward pump motor with a V-Green EVO variable speed motor. I got this from inyopools and they sent new o-rings along with the motor.

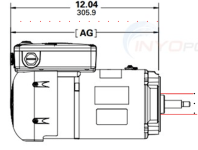

I've gotten everything re-assembled to the point where I have to insert the diffuser+impeller back in and the seal plate flush with the pump body. See attached pic. I'm unable to get enough force to get the assembly back in there. The new o-ring just makes too tight of a fit. I've lubed everything, and even warmed the o-ring in hot tap water. Anyone have any tips?

Thanks!

I am replacing my Hayward pump motor with a V-Green EVO variable speed motor. I got this from inyopools and they sent new o-rings along with the motor.

I've gotten everything re-assembled to the point where I have to insert the diffuser+impeller back in and the seal plate flush with the pump body. See attached pic. I'm unable to get enough force to get the assembly back in there. The new o-ring just makes too tight of a fit. I've lubed everything, and even warmed the o-ring in hot tap water. Anyone have any tips?

Thanks!