The 3/4" galvanized metal pipe is a major source of restriction.

PVC might have been legal when it was installed, but it is probably not legal today.

You might be able to legally repair it, but I would recommend a full replacement.

_____________________________________________________________________________________________

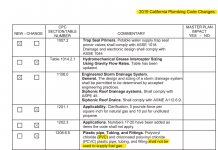

1208.6.5 Plastic Pipe, Tubing, and Fittings

Polyethylene plastic pipe, tubing, and fittings used to supply fuel gas shall conform to ASTM D2513. Pipe to be used shall be marked "gas" and "ASTM D2513."

Polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) plastic pipe, tubing, and fittings shall not be used to supply fuel gas. [NFPA 54.5.6.4.1.1 — 5.6.4.1.3]

_____________________________________________________________________________________________

1208.6.5 Plastic Pipe, Tubing, and Fittings.

Plastic pipe, tubing, and fittings shall be used outside underground only and shall conform with ASTM D 2513, Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and Fittings. Pipe to be used shall be marked "gas" and "ASTM D 2513." [NFPA54: 5.6.4.1]

_____________________________________________________________________________________________

ASTM F2817-10

Standard Specification For Poly (Vinyl Chloride) (PVC) Gas Pressure Pipe And Fittings For Maintenance Or Repair

1.1 This specification covers requirements for PVC pipe and tubing for use only to maintain or repair existing PVC gas piping. This specification covers requirements for fittings for use to maintain or repair existing PVC gas piping.

_____________________________________________________________________________________________

AbstractThis specification covers the requirements and test methods for material, dimensions, hydrostatic burst strength, tensile strength, chemical resistance, sustained pressure, heat fusion, and impact resistance of plastic pipes, tubing, and fittings

www.astm.org