I've read quite a lot here on plumbing and pipes and old posts about no bubbles in spa jets, but since we have a new pool (well, old pool, but all new piping), I feel like our problems are because our pool builder didn't design it properly. I'd love your perspective.

Problem: Spa jets have weak flow and no bubbles.

Equipment: Hayward SwimClear C4030 filter, 2.7HP Hayward pump/motor, Jandy heater with diverter

Design: See photos. 30-foot air pipe from pool equipment to the spa. Air can be force-blown into the pipe (no blockage). There's no blower (but because the spa isn't working, the builder says he'll comp a blower, but that won't fix the weak jets). The water return pipes have some sort of reducer inside the pipe (need some extension tool they used to remove them).

We previously had 3 jets (each with two openings, top/bottom) and when we ran with a 1.5HP pump, the jets (max flow) would spray across the spa pretty hard. We specifically asked for two extra jets (never mind that they did a really stupid design and just put the jets between the other three, leaving a seat gap without a jet--first clue of bad design?)

Now (see photos), on max flow with a 2.7HP Hayward pump/motor, the jets barely pump out. We wondered what would change if we plugged some of the jets (with our fingers), and what happened is that water ran up through the air pipe and spilled out at the opening (by the pool equipment).

The pool has three returns that have high flow/pressure (gaging just by feel), whereas in the spa, the jets are all weak.

Can this be fixed? I have very little confidence now that we hired a professional (lots of other things wrong but this is a major issue).

Thank you!

Weak spa jets. This is 100% max flow:

Pool equipment (and yes, for all new install, I'm well aware now of the bad design, many bends, etc); air pipe is 3rd from right front:

Two rows of jets supplied by one return line (middle, 90° bend):

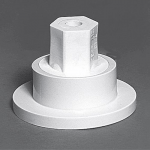

Air line goes up and over then reduces

(at least this is my best guess--I'm no expert). Second image is labeled:

Narrow pipes tied in to water jets/return but not yet connected to the air inlet shown above:

Problem: Spa jets have weak flow and no bubbles.

Equipment: Hayward SwimClear C4030 filter, 2.7HP Hayward pump/motor, Jandy heater with diverter

Design: See photos. 30-foot air pipe from pool equipment to the spa. Air can be force-blown into the pipe (no blockage). There's no blower (but because the spa isn't working, the builder says he'll comp a blower, but that won't fix the weak jets). The water return pipes have some sort of reducer inside the pipe (need some extension tool they used to remove them).

We previously had 3 jets (each with two openings, top/bottom) and when we ran with a 1.5HP pump, the jets (max flow) would spray across the spa pretty hard. We specifically asked for two extra jets (never mind that they did a really stupid design and just put the jets between the other three, leaving a seat gap without a jet--first clue of bad design?)

Now (see photos), on max flow with a 2.7HP Hayward pump/motor, the jets barely pump out. We wondered what would change if we plugged some of the jets (with our fingers), and what happened is that water ran up through the air pipe and spilled out at the opening (by the pool equipment).

The pool has three returns that have high flow/pressure (gaging just by feel), whereas in the spa, the jets are all weak.

Can this be fixed? I have very little confidence now that we hired a professional (lots of other things wrong but this is a major issue).

Thank you!

Weak spa jets. This is 100% max flow:

Pool equipment (and yes, for all new install, I'm well aware now of the bad design, many bends, etc); air pipe is 3rd from right front:

Two rows of jets supplied by one return line (middle, 90° bend):

Air line goes up and over then reduces

(at least this is my best guess--I'm no expert). Second image is labeled:

Narrow pipes tied in to water jets/return but not yet connected to the air inlet shown above: