You have to install two main drain fixtures or a single channel drain if it's listed as suitable for single unblockable use.

You can't just install pipe or a hole.

You can't just install pipe or a hole.

Thanks for the response. Yes, I'm aware of that, which is why I said this in my post "This would presumably mean drilling a pair of 3" holes (for anti suction entrapment purposes) through the gunite shell sidewall of the pool."You have to install two main drain fixtures or a single channel drain if it's listed as suitable for single unblockable use.

You can't just install pipe or a hole.

The holes would be closer to 8" in diameter so that you can install the whole fixtures."This would presumably mean drilling a pair of 3" holes (for anti suction entrapment purposes) through the gunite shell sidewall of the pool."

The holes would be closer to 14" in diameter so that you can install the whole fixtures.

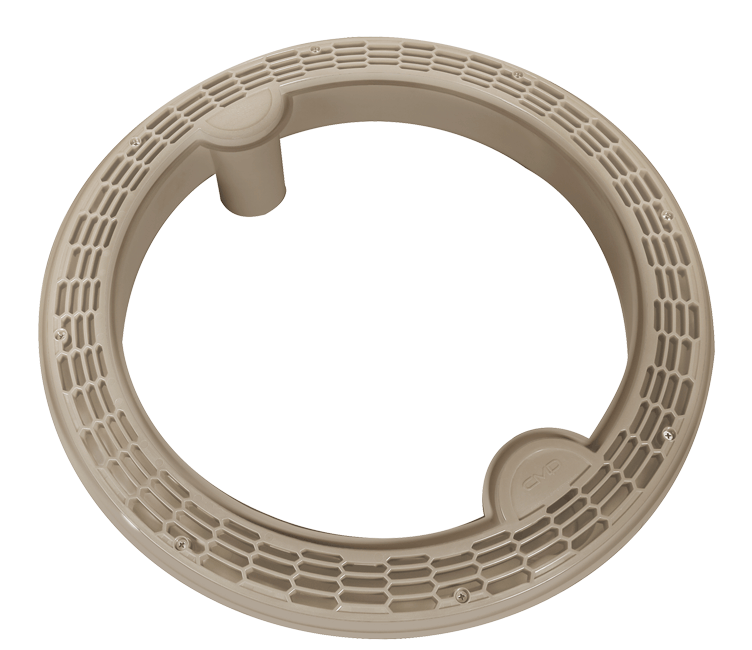

No. As shown in the previous picture and in the installation manual, the fixture or fixtures are installed before gunite is shot so that the fixtures are embedded in the concrete.As far as just the construction of this drain goes, does this look okay to you at this stage of construction?

Yes. Two skimmers, each home runned back to the equipment pad via their own 2” dedicated pipe.Do you have any skimmers on this pool?

Yes. If you look at the post gunite picture, you can see one skimmer in the side of the pool that’s closest to the house, about 5 feet before you get to the spa. The other skimmer is a little harder to see, but you can see the top of it. It is in the opposite side wall of the pool (the pool wall that’s furthest from the house), and it’s almost at the end of that wall towards the fence that you can see.Are they already installed? I don't see them.

For example, if the gunite is 8" thick, it should be 4" on both sides of the rebar.Another problem is that the pipe is in the gunite, which creates a control joint type weak line in the gunite.

For example, if the gunite is 8" thick, it should be 4" on both sides of the rebar.

A 2.5" pvc pipe has an outside diameter of 2.875".

Behind the rebar, you have 2.875" of pipe, which means that the thickness of the concrete behind the pipe is only 1.125".

It's even less if you take the thickness of the rebar into consideration.

Also, the pipe will block most concrete from getting behind the pipe.

This is called "shadowing".

So, there's a line through the concrete that's really only 4" thick, which is likely to crack if there is any stress at all.