- Nov 12, 2017

- 12,658

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

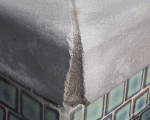

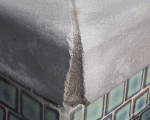

The weirdness on the ends of some of the joints might be due to the slope that the tiles are supposed to have. Where two sloped surfaces meet for a 90° corner (or any angle) it requires a compound-miter cut. Which is just as easy to do as the cut you have, if the setter has the right tool and the right skill. So it is not unreasonable to expect that not only should the joint not be all ragged and chipped, but that the grout line should be of the same width on the vertical surface as it is on the horizontal surface (not growing wider from one edge to the other).