Hi all, thanks for contributing to the discussion. I could only add some more now...

Bama, how did you get to such an estimate?Please note further below my rough estimates.

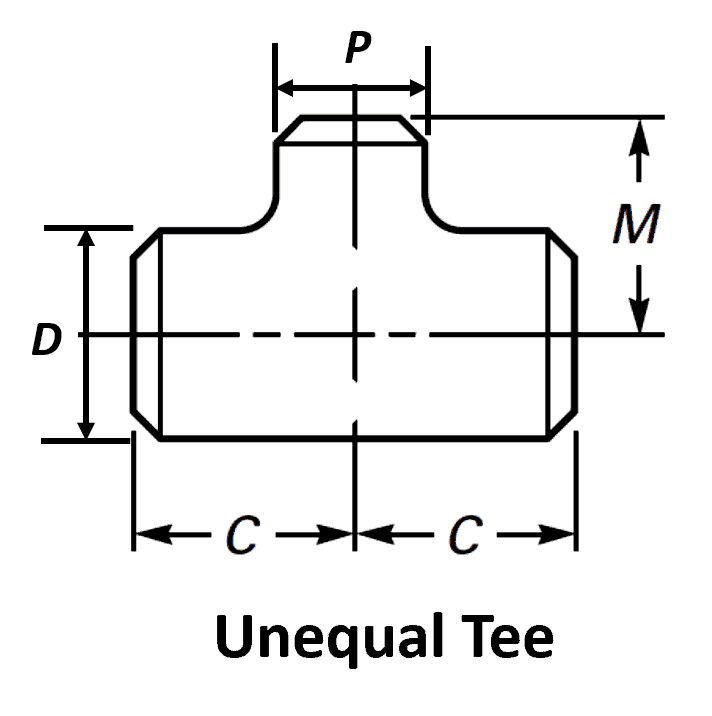

I wanted to keep the tees as small as possible to ensure that I can fit as many pipes as possible within a panel. Using 1.5 " reducing Ts would lead to quite a bit of spacing since each T is (2x57mm) 4 inches wide:

Standard Reducing & Equal Pipe Tee Dimensions as per ASME B16.9. For the tee that used in oil & gas and power piping.

hardhatengineer.com

I'm not sure if it is important to have such a large main in each panel such as this or other commercial products. They may be able to manufacture their main channel very large with tiny reducers but I cannot:

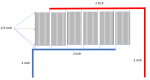

I would have the main feed line feed all the panels in "parallel" instead as I show below to keep using 1/2 inch tees within each panel. Something like this:

My Cost Estimate

My Cost Estimate

- 10 ft 1/2 inch schedule 40 pipe at HD in bulk is $ 1.62 each

Finish your plumbing projects by utilizing this rustic PVC Plain-End Pipe. Comes with everlasting durability and reliability.

www.homedepot.com

- 1/2 inch Ts are 44 c. each

PVC schedule 40 pipe and pressure fittings are used in irrigation, underground sprinkler systems, swimming pools, outdoor applications and cold water supply lines. These fittings are highly resilient,

www.homedepot.com

A 1/2 inch T would be 50 mm (~2 inch) wide, so:

In a single 4 ft (48 inch) wide layer, we can place 24 pipes/Ts.

Double layered requires 48 pipes / Ts. There would be slight horizontal spacing between the overlapping pipes.

So the cost of a double layer as I can see would be 48 x (1.62 + 44) = $ 98.88. That's ~500 ft. Which gives us 0.7 cu. ft. or 5.2 Gal.

As you mention, need to add glue, connection to main and also black (high quality) paint.

Single layered panel weight is at least 24 * 1.643 lb = 40 lbs. Best keep them separate until the install on the roof.

Compared to Heliocol's 4x10 panel (from Amazon), is 24 lbs.

Sizing of collectors

Seems that 1/8 or 1/4 inch are more expensive and not easy to find so let's forget about those... unless if someone can help find Ts and other fittings.

A thought about "smaller is better". I'm not sure... if you slow down the flow rate enough, I believe the temperature will rise just the same. So it might also be possible to do this with 3/4. Or? What are your thoughts? Of course you'll need the same total throughput.

So, for example, using 3/4 inch pipes (~2.3 inches wide end to end) we can only fit 20 pipes (single) or 40 pipes in double in 4 ft wide panels. But, the area of a 3/4 inch pipe is 0.44 sq in compared to 0.2 sq in for a 1/2 inch pipe, so we'd have more than double the amount of water in the pipe getting heated. If the flow rate at the pump remains the same, it would mean that water remains in the pipes longer before returning to the pool. Basically, more water in the collectors during the same period of time.

I am in AZ, so pool is warm enough now, and have too much on my plate now anyway but plan to try something out before end of season. At least a prototype.

Allen