Infloor cleaning system, troubleshooting tips and maintenance desired

- Thread starter IaMac

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FWIW I measured the complete cycle time for the IFCS at 2400 RPM, it was 10:30. Compare that to 3450 RPM = 4:00. So how many cycles does it take for all the pop-ups to complete their rotational cycle ? How many of these "cleaning" cycles do you want in a day ?

PS - I don't have the manual handy ATM but I believe the pop-ups can be restricted in their angular sweep. This would imply that some might do more than 1 pop-up cycle in a cleaning cycle.

PS - I don't have the manual handy ATM but I believe the pop-ups can be restricted in their angular sweep. This would imply that some might do more than 1 pop-up cycle in a cleaning cycle.

Dodger

Silver Supporter

Mac, your head loss is only slightly more than mine was. Based on my results, I would say don't worry as much about the rest of the plumbing, and start with a relatively simple heater bypass. You can see the results of my endeavor here:

www.troublefreepool.com

www.troublefreepool.com

If you don't get quite enough bang for your buck on that project, then I agree with @proavia that removing the check valve is the next low-hanging piece of fruit.

Pressure loss between filter and Caretaker

I am thinking about a replumbing job to improve the pressure at my Caretaker valve so the filter is not overtaxed. For example, at 3000 rpm I get about 7-8 psi loss between the filter and the Caretaker (twenties down to lower teens). On 1 or 2 stations, this still gives enough pressure to the...

If you don't get quite enough bang for your buck on that project, then I agree with @proavia that removing the check valve is the next low-hanging piece of fruit.

Dodger

Silver Supporter

The cycle time trend that you quote jibes with my Caretaker, which runs shorter cycles at higher pressure. This is even noticeable zone to zone, where my highest pressure zone (spa) always has a shorter hang time than the rest of the zones.FWIW I measured the complete cycle time for the IFCS at 2400 RPM, it was 10:30. Compare that to 3450 RPM = 4:00. So how many cycles does it take for all the pop-ups to complete their rotational cycle ? How many of these "cleaning" cycles do you want in a day ?

PS - I don't have the manual handy ATM but I believe the pop-ups can be restricted in their angular sweep. This would imply that some might do more than 1 pop-up cycle in a cleaning cycle.

The number of cycles or hours per day required really depends on when your pool is cleaned to your satisfaction. My Caretaker system is simple and all heads rotate a 20 degree increment at the end of each cycle, so that I should get a full rotation of all pop-ups after 18 cycles. Depending on my pump rpm, that full rotation takes about 1.5-1.75 hours. I think the vendor says to run it something like 5-6 hours per day, but I don't usually run it that long.

In my area, we have lots of Spring pollen, so during those weeks (~April/May), I run it a lot more frequently for 3+ hours per day. But not every day. We aren't swimming then, so it's only aesthetics, and I balance that with the higher electricity costs.

During the summer, I only run the floor system about once or twice per week for less than an hour to help distribute water after an MA addition, or to run an ad hoc clean for 2 or 3 hours after we have a little wind blow twigs and such into the pool.

During winter, I hardly run it at all.

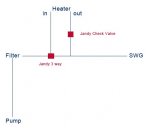

That's a great piece of information (your linked results) ! I was wondering about the amount of hard 90 deg bends as well. I'd have bet a dollar that replacing those would make a bigger difference. Is your heater bypass just a smaller diameter pipe between the input and output, as shown in a file I was given? Or do you have a proportioning valve that can vary the amout of bypass?Mac, your head loss is only slightly more than mine was. Based on my results, I would say don't worry as much about the rest of the plumbing, and start with a relatively simple heater bypass. You can see the results of my endeavor here:

My copper pipe sweating skill is so-so but gluing PVC...

PS: Not to derail the thread but I can really begin to see the advantages of a user-friendly flexible pool automation system.

Last edited:

Dodger

Silver Supporter

Well, I didn’t do the easy tee between heater input and output right in front of the heater. I was still fueled by the need (erroneous as it turned out) to shorten the total path as much as possible, so I put a 3-way valve further upstream to feed the SWG asap and get around to the IFCS. I was fixing a couple of unnecessary jogs in the line too so I could remove a couple of elbows completely.

In hindsight, I wish I had just plumbed it as a tee across input and output. I think I would have stuck with 2 inch pipe. Not sure I could squeeze a Jandy3-way 2-way, but would have wanted to avoid a ball valve.

I did put an actuator upstream, so I can automate that heater bypass along with the actuator I added to the IFCS bypass. Turns out I only need to open the heater bypass by ~40-45 degrees to see max psi on my IFCS.

In hindsight, I wish I had just plumbed it as a tee across input and output. I think I would have stuck with 2 inch pipe. Not sure I could squeeze a Jandy

I did put an actuator upstream, so I can automate that heater bypass along with the actuator I added to the IFCS bypass. Turns out I only need to open the heater bypass by ~40-45 degrees to see max psi on my IFCS.

Last edited:

- Feb 6, 2015

- 7,813

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Personally, if I was going to install a heater bypass, I would cut that check valve out and toss it - it' not in a good place to re-use it in the heater bypass anyway - and you don't want 2 check valves restricting flow when using the heater. Do it once and be done with it. Use a Jandy 3-way valve and a Jandy check valve of the same pipe size as your present plumbing. Adding a few 90's isn't going to appreciably affect the head.If you don't get quite enough bang for your buck on that project, then I agree with @proavia that removing the check valve is the next low-hanging piece of fruit.

And no copper pipe sweating required - all PVC glue.My copper pipe sweating skill is so-so but gluing PVC...

Dodger

Silver Supporter

That schematic pretty much represents my re-plumb, though I was reminded previously that I failed to add the check valve. I may go back and do it at some point, partly because my SWG is about 20 inches above the output from the heater.

Not to crash this thread of really experienced people, but could I post a pic of my new pool plumbing and get your input? The A&A rep is coming back after the 4th to make some changes, and I'm not sure how interested he is in how 'we' want this to run. I'm getting the impression he'll just do it the way 'he' wants. Apparently we're the only people who actually want to completely turn off the pop ups and he believes everyone should want the stellar circulation of the pop ups even if you stub your toe or have them shooting water at your leg while you sit on a bench. Then we have the complication of the heat pump and SWG and how those impact the flow/pressure. If it's better that I start a new thread, let me know. I realize these aren't popular on this site (and I get it...but we were too far along in the process before I found this site...so we have it). Thanks!

This statement from Dodger has me scratching my head. Looking at proavia's diagram, you could have replaced the Jandy 3way with a T and put a valve in the line between the heater input and output T's. A simple valve, 1 input, 1 output, like a ball valve.In hindsight, I wish I had just plumbed it as a tee across input and output. I think I would have stuck with 2 inch pipe. Not sure I could squeeze a Jandy 3-way, but would have wanted to avoid a ball valve.

So why is a ball valve to be avoided in this situation? Is my alternate plumbing somehow worse? Is it that PVC ball valves are Crud construction vs a 3way ? Looking at what's on my pad, I can believe this statement. Is is because there are no servo ball valves, just servo 3ways ?

Can't learn if you don't ask.

Dodger

Silver Supporter

I follow the advice of the experienced guys on here who say that ball valves get stuck as they age and don't move well. (Kinda like humans?)

- Feb 6, 2015

- 7,813

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

It would be best if you start your own thread and we can respond to you directly there. Pictures encouraged.Not to crash this thread of really experienced people, but could I post a pic of my new pool plumbing and get your input? The A&A rep is coming back after the 4th to make some changes, and I'm not sure how interested he is in how 'we' want this to run. I'm getting the impression he'll just do it the way 'he' wants. Apparently we're the only people who actually want to completely turn off the pop ups and he believes everyone should want the stellar circulation of the pop ups even if you stub your toe or have them shooting water at your leg while you sit on a bench. Then we have the complication of the heat pump and SWG and how those impact the flow/pressure. If it's better that I start a new thread, let me know. I realize these aren't popular on this site (and I get it...but we were too far along in the process before I found this site...so we have it). Thanks!

Last edited:

- Feb 6, 2015

- 7,813

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Puting a valve between the input and output pipes to the heater will NOT allow you to fully bypass the heater. So if your heater springs a leak or you need to drop the pH to do a no-drain acid wash or...... - you have no way to isolate the heater from the system.This statement from Dodger has me scratching my head. Looking at proavia's diagram, you could have replaced the Jandy 3way with a T and put a valve in the line between the heater input and output T's. A simple valve, 1 input, 1 output, like a ball valve.

So why is a ball valve to be avoided in this situation? Is my alternate plumbing somehow worse? Is it that PVC ball valves are Crud construction vs a 3way ? Looking at what's on my pad, I can believe this statement. Is is because there are no servo ball valves, just servo 3ways ?

Can't learn if you don't ask.

Those ball valves are cheap and after a few years will leak or freeze up. The Jandy valve can be rebuilt if needed - mine are almost 20 years old and have never been rebuilt. The neighbor has replaced his ball valves at least 4 times in the same amount of time. He still swears it's cheaper doing it his way - his wife told my wife different.

I'll go back to what I said in my previous post - Do it once and be done with it. You try to shortcut it or do it on the cheap and you will be destined to re-do it - again and again.

jonpcar

Bronze Supporter

This statement from Dodger has me scratching my head. Looking at proavia's diagram, you could have replaced the Jandy 3way with a T and put a valve in the line between the heater input and output T's. A simple valve, 1 input, 1 output, like a ball valve.

I don't have a heater nor a bypass, but here is what I have gleaned through reading the various threads.

I don't think Mac is really asking about a "ball valve", he is asking about a simple 2-port valve...open/close between the heater input/output, with NO check valve. Mac, I'm with you on this, I would consider doing it that way...the only "legitimate reason" I have seen for doing it the way Gene proposes (and that is always how it is proposed) is that IF your heater coil gets a leak in it...you can take the heater completely out of the system with that 3way valve/check valve. (But if you don't have a bypass you still have to deal with this so to me it makes no sense).

Another way I have seen it put is that you don't want to keep all that pressure in the heater coils if you are not using it (which still doesn't make sense for the same reason).

But...it seems to me there are some legitimate reasons for doing it the way you propose: I always go back to the resistors (heater = 10ohm high resistance, valve = 1 ohm low resistance)...when the valve is closed you would go through the 10ohm heater (and you don't have to go through a check valve), when the valve is open, the 10ohm heater and the 1ohm valve are in parallel and make a better bypass than just the valve alone. In addition, there is a constant small stream of clean water through the heater that seems to be less likely to develop rust, etc.

Once again...that is what I have always wondered about. Gene's and Dodger's implementations can accomplish the benefits I listed by setting the 3-way to a partial open as Dodger does.

In any case, don't be chintzy...use a JANDY valve because at some point you will want to automate.

OOPS Gene jumped in between my post and the previous...and there it is...the famous take the heater out argument, haha.

Last edited:

I can testify in the affirmative to both of the above. Three of four ball valves in my system are sticky and 1 of the 3 doesn't seem work when twisted. That said there's one different 2way valve that seems OK, hence my words about crud construction. Proavia makes a good point in that (along with a check valve) a 3way, as drawn in his diagram, allows for the heater to be isolated if need be.I follow the advice of the experienced guys on here who say that ball valves get stuck as they age and don't move well. (Kinda like humans?)

ETA: Seems that jonpcar was posting as I was typing. He has collected my thoughts precisely.

- Feb 6, 2015

- 7,813

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Another reason to use the 3 way Jandy and check valve arrangement is that you can "winterize" the heater prior to shutting down the entire system. With Mac being in New Hampshire, that is a possible consideration. Also, when opening the pool, it allows you to get the pool in balance prior to running the pool water thru the heater. To me, that arrangement allows more flexibility.

jonpcar

Bronze Supporter

You've convinced me...and as I said, you can still reap the benefits by partially opening a 3-way...as Dodger attests, partially opening (more than just a tad) is effectively opening it all the way...Another reason to use the 3 way Jandy and check valve arrangement is that you can "winterize" the heater prior to shutting down the entire system. With Mac being in New Hampshire, that is a possible consideration. Also, when opening the pool, it allows you to get the pool in balance prior to running the pool water thru the heater. To me, that arrangement allows more flexibility.

Oh and don't reduce the pipe size...match the valve size to the pipe size (is yours 2")?

Dodger

Silver Supporter

All, sorry to have mis-typed in post #86. Though it led to good discussion of having the ability to isolate the heater, I meant to type Jandy 2-way, and have corrected that post.

Doing that (or a ball valve) would have matched the vendor installation instructions for my Caretaker IFCS. I wasn't smart enough at the time to plan for heater isolation. If I was, I wouldn't have left out the check valve!

Doing that (or a ball valve) would have matched the vendor installation instructions for my Caretaker IFCS. I wasn't smart enough at the time to plan for heater isolation. If I was, I wouldn't have left out the check valve!

jonpcar

Bronze Supporter

@Dodger is going to be thinking…”oh, please not again”…sorry Dodger.

Gene, I am rewriting a previous post to you just to make sure people “get it”; unfortunately, it also reveals my rather obsessive beliefs about this topic (haha). That post was important because it contains one of the key, actually measurable values to back up my view. Lots of times we have to "judge" results (does it look cleaner?)...this isn't one of those times...this is real, hard data.

My "experiments" have shown that at low RPMs, my IFCS is, in fact, a giant check valve. And, because of the way IFCSs operate, this is not unique to my system. I haven't yet been successful in convincing anyone to take measurements in their system to corroborate this, Dodger wouldn't play, haha. I keep hoping that someone else will try it, but it really doesn't matter because the data doesn't lie.

Gene, you indicate that you get 2psi "back pressure" when running your IFCS at low RPMs. That is exactly what I get, too. But that deceptively low PSI number should NOT be ignored. 2 PSI (at very low flow rates/RPMs) is actually a substantial "impediment." In fact, in my system, it pretty much negates all the efficiency advantages of running a "high efficiency VSP" at low RPMs. Look at Energy Factor in the chart below.

For now, I am going to ignore this question (and it IS a valid question)…Is it worth it? Cost/Gain/Trouble. But I will answer it for me…absolutely. For those having a new IFCS designed @Poolmama! the incremental changes in cost are pretty much zero. YES Poolmama, you do want a method to take your IFCS “out of the loop”, but personally I wouldn’t count “stubbing your toes on the popups” as one of the reasons .

.

For as much talk about VSPs and their efficiency on this site, I find it very strange (as an Electrical Engineer) that there is absolutely NO discussion about the underlying reason for this efficiency. They are efficient because they have the “capability” to move more water (GPM) at a lower cost (fewer watts) than other pumps. But if they are installed inappropriately, or in the wrong circumstances (many are due to the really simple example below), this efficiency “advantage” can be lost or substantially reduced…even in pools with very, very simple plumbing designs. People tend to look at the watts number and think they are saving money because it is lower…not really the case. VSP’s energy efficiency is a function of their GPM/watts ratio, not because of their watts number.

Here is an example for a simple pool with a VSP, an adequately sized filter, 2 wall returns, and a skimmer: A factor as simple as having the wrong size opening (say 1/2” vs 3/4”) on the wall returns could easily cut your low RPM VSP efficiency number by more than half. It WILL cost that pool owner twice as much as it COULD to filter, chlorinate, & skim their pool than if he simply changed out his nozzles. Those nozzles (like our popups) introduce restrictions, and it doesn’t take much, to really impact a pump’s Energy Factor.

I’ve actually tested this example (wall return nozzles) on my pool because I was experimenting with special Venturi nozzle heads on my wall returns…TOO restrictive, my EF (energy factor) was cut by more than half when running at low RPMs.

As we know, heaters that are not bypassed also cause big problems for IFCSs...they WILL cause a reduction in non-IFCS systems efficiencies as well, how much (or if it makes a “real impact”) is going to depend on lots of things...I can’t test that . Same possibility for SWGs. I can’t test those (heater, SWG), I don’t have either. But has anyone? Is it possible that all the money being “saved” by generating chlorine (even with a VSP) is eaten up by hidden inefficiencies introduced to the VSPs by SWGs?...I suspect that one might be ex-communicated from this site for mentioning that without actual data (that last part is a joke). I don’t have data, and don’t understand head like the experts in this forum...but I still wonder.

Who says, “check your wall return nozzle sizes” when a poster excitedly posts that they have installed a new VSP and are going to save lots of money? Who says bypass your heater? No-one…it never occurs, except in those rare situations where those posters realize that something is not quite right with their system…and usually they are looking at their GPM numbers (provided on some VSPs)…something that is almost considered sinful on these boards (can you tell I was raised Catholic?). But, GPM/watt is the key to a VSPs Energy Factor, and my data seems to indicate it is pretty easy to screw it up.

Efficiency improvement is one factor (cost), but in my case it’s actually not the driving issue for my passion. Saving an additional $2/month (off my normally $10/month pool electrical bill) is not why I am so adamant about this. Effectiveness of my IFCS has improved dramatically with this change (unfortunately, effectiveness can NOT be scientifically measured).

Because I bypass the IFCS popups, the much higher water flows that I get when low speed skimming/filtering (@1200 rpm) really does make my pool cleaner. Skimming is FREE and, with the change, it skims at a much higher GPM for roughly the same cost. It is more efficient and more effective to collect debris on the surface than it is to let it fall to the pool floor where the IFCS randomly pushes it around (at a high cost, “high pressure) before it is removed.

So once again, I am going to post my ACTUAL, measured numbers to show the impact of being able to “bypass” my IFCS by using 100% return to the wall returns during low speed skimming/filtering. By the way, some IFCS’s are not even designed with the ability to “add” this capability (PoolMama! take heed). That is a huge mistake in my mind.

I know Energy Factor isn’t discussed on this site (mainly for the reason I stated…you need to know your GPM). But take a close look at it in my chart. It really is THE determining factor for VSP efficiency.

Finally, I will state another time that to take full advantage of a VSP’s efficiency and effectiveness in a system with an IFCS, it really requires automation to change those valve settings when you change your pump RPMs from cleaning (high rpms) to skimming/chlorinating/filter (low rpms). I can’t imagine doing this manually each day, or possibly every few days if that is how you choose to run your IFCS.

Sorry for all the wordiness…based on my experiments with my IFCS, this is one of the simplest and measurable ideas that I have about making your IFCS work well. I’m retired and have time to spend on this (one of my current) hobbies. But, I perfectly understand that these discussions don’t interest many…I will try to minimize these long, boring lectures.

Gene, I am rewriting a previous post to you just to make sure people “get it”; unfortunately, it also reveals my rather obsessive beliefs about this topic (haha). That post was important because it contains one of the key, actually measurable values to back up my view. Lots of times we have to "judge" results (does it look cleaner?)...this isn't one of those times...this is real, hard data.

My "experiments" have shown that at low RPMs, my IFCS is, in fact, a giant check valve. And, because of the way IFCSs operate, this is not unique to my system. I haven't yet been successful in convincing anyone to take measurements in their system to corroborate this, Dodger wouldn't play, haha. I keep hoping that someone else will try it, but it really doesn't matter because the data doesn't lie.

Gene, you indicate that you get 2psi "back pressure" when running your IFCS at low RPMs. That is exactly what I get, too. But that deceptively low PSI number should NOT be ignored. 2 PSI (at very low flow rates/RPMs) is actually a substantial "impediment." In fact, in my system, it pretty much negates all the efficiency advantages of running a "high efficiency VSP" at low RPMs. Look at Energy Factor in the chart below.

For now, I am going to ignore this question (and it IS a valid question)…Is it worth it? Cost/Gain/Trouble. But I will answer it for me…absolutely. For those having a new IFCS designed @Poolmama! the incremental changes in cost are pretty much zero. YES Poolmama, you do want a method to take your IFCS “out of the loop”, but personally I wouldn’t count “stubbing your toes on the popups” as one of the reasons

For as much talk about VSPs and their efficiency on this site, I find it very strange (as an Electrical Engineer) that there is absolutely NO discussion about the underlying reason for this efficiency. They are efficient because they have the “capability” to move more water (GPM) at a lower cost (fewer watts) than other pumps. But if they are installed inappropriately, or in the wrong circumstances (many are due to the really simple example below), this efficiency “advantage” can be lost or substantially reduced…even in pools with very, very simple plumbing designs. People tend to look at the watts number and think they are saving money because it is lower…not really the case. VSP’s energy efficiency is a function of their GPM/watts ratio, not because of their watts number.

Here is an example for a simple pool with a VSP, an adequately sized filter, 2 wall returns, and a skimmer: A factor as simple as having the wrong size opening (say 1/2” vs 3/4”) on the wall returns could easily cut your low RPM VSP efficiency number by more than half. It WILL cost that pool owner twice as much as it COULD to filter, chlorinate, & skim their pool than if he simply changed out his nozzles. Those nozzles (like our popups) introduce restrictions, and it doesn’t take much, to really impact a pump’s Energy Factor.

I’ve actually tested this example (wall return nozzles) on my pool because I was experimenting with special Venturi nozzle heads on my wall returns…TOO restrictive, my EF (energy factor) was cut by more than half when running at low RPMs.

As we know, heaters that are not bypassed also cause big problems for IFCSs...they WILL cause a reduction in non-IFCS systems efficiencies as well, how much (or if it makes a “real impact”) is going to depend on lots of things...I can’t test that . Same possibility for SWGs. I can’t test those (heater, SWG), I don’t have either. But has anyone? Is it possible that all the money being “saved” by generating chlorine (even with a VSP) is eaten up by hidden inefficiencies introduced to the VSPs by SWGs?...I suspect that one might be ex-communicated from this site for mentioning that without actual data (that last part is a joke). I don’t have data, and don’t understand head like the experts in this forum...but I still wonder.

Who says, “check your wall return nozzle sizes” when a poster excitedly posts that they have installed a new VSP and are going to save lots of money? Who says bypass your heater? No-one…it never occurs, except in those rare situations where those posters realize that something is not quite right with their system…and usually they are looking at their GPM numbers (provided on some VSPs)…something that is almost considered sinful on these boards (can you tell I was raised Catholic?). But, GPM/watt is the key to a VSPs Energy Factor, and my data seems to indicate it is pretty easy to screw it up.

Efficiency improvement is one factor (cost), but in my case it’s actually not the driving issue for my passion. Saving an additional $2/month (off my normally $10/month pool electrical bill) is not why I am so adamant about this. Effectiveness of my IFCS has improved dramatically with this change (unfortunately, effectiveness can NOT be scientifically measured).

Because I bypass the IFCS popups, the much higher water flows that I get when low speed skimming/filtering (@1200 rpm) really does make my pool cleaner. Skimming is FREE and, with the change, it skims at a much higher GPM for roughly the same cost. It is more efficient and more effective to collect debris on the surface than it is to let it fall to the pool floor where the IFCS randomly pushes it around (at a high cost, “high pressure) before it is removed.

So once again, I am going to post my ACTUAL, measured numbers to show the impact of being able to “bypass” my IFCS by using 100% return to the wall returns during low speed skimming/filtering. By the way, some IFCS’s are not even designed with the ability to “add” this capability (PoolMama! take heed). That is a huge mistake in my mind.

| RPM | GPM | Watts | mPSI | fPSI | Energy Factor | |

| Returns through Popups | 1207 | 11 | 140 | 2 | 2 | 4.7 |

| Returns through Popups | 1035 | 9 | 136 | 2 | 2 | 4 |

| Returns through Wall Returns | 1207 | 35 | 161 | 0 | 0 | 13 |

| Returns through Wall Returns | 1035 | 28 | 136 | 0 | 0 | 12.3 |

I know Energy Factor isn’t discussed on this site (mainly for the reason I stated…you need to know your GPM). But take a close look at it in my chart. It really is THE determining factor for VSP efficiency.

Finally, I will state another time that to take full advantage of a VSP’s efficiency and effectiveness in a system with an IFCS, it really requires automation to change those valve settings when you change your pump RPMs from cleaning (high rpms) to skimming/chlorinating/filter (low rpms). I can’t imagine doing this manually each day, or possibly every few days if that is how you choose to run your IFCS.

Sorry for all the wordiness…based on my experiments with my IFCS, this is one of the simplest and measurable ideas that I have about making your IFCS work well. I’m retired and have time to spend on this (one of my current) hobbies. But, I perfectly understand that these discussions don’t interest many…I will try to minimize these long, boring lectures.

Last edited:

- Feb 6, 2015

- 7,813

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Many infloor users don't have the option to route the return flow thru separate returns.

At lower rpms, I don't think the mechanical gauge pressure resolution is as good as at higher pump rpms. I do not notice any difference in the quantity of water entering the skimmer when returns set to infloor versus separate returns. Granted, eye balling it is probably not that accurate. I guess one could set up some type of high resolution measuring device on the suction size to measure the quantity of water. I don't think a flow-meter would offer precise enough accuracy. Me, I'm just happy my system works as well as it does. While I do have the time to mess with the system, I don't relish in being out by the equipment pad in 105*+ temps - rather be in the pool or in the A/C. ?

As for @Poolmama! - hopefully she will start her own thread so we can discuss her questions there and not bury info pertinent to her concerns in this post.

At lower rpms, I don't think the mechanical gauge pressure resolution is as good as at higher pump rpms. I do not notice any difference in the quantity of water entering the skimmer when returns set to infloor versus separate returns. Granted, eye balling it is probably not that accurate. I guess one could set up some type of high resolution measuring device on the suction size to measure the quantity of water. I don't think a flow-meter would offer precise enough accuracy. Me, I'm just happy my system works as well as it does. While I do have the time to mess with the system, I don't relish in being out by the equipment pad in 105*+ temps - rather be in the pool or in the A/C. ?

As for @Poolmama! - hopefully she will start her own thread so we can discuss her questions there and not bury info pertinent to her concerns in this post.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.