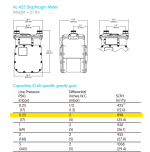

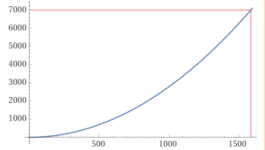

For 1.25” pipe, we can estimate the pressure drop in milliinches to be about 0.00312500F^2 per 100 foot of pipe.

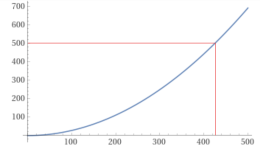

For 1.5” pipe, we can estimate the pressure drop in milliinches to be about 0.00138889F^2 per 100 foot of pipe.

F = CFH

For a 1.25” pipe at 400 CFH, we can estimate the pressure drop in milliinches to be about 500 milliinch per 100 foot of pipe.

For 1.5” pipe at 400 CFH, we can estimate the pressure drop in milliinches to be about 222 milliinch per 100 foot of pipe.

If half the pipe (61 feet) is 1.25” and half the pipe (61 feet) is 1.5”, then the total pressure drop is 0.61 (500 + 222) = 440 milliinches or 0.440”, which would be acceptable.

0.305” for the 1.25” pipe and 0.135” w.c for the 1.5” pipe.

However, I would just follow the manufacturer’s recommendation and do all 1.5” pipe.

If there is ever a warranty issue, you do not want to try to explain this to the manufacturer.

______________________________________________________

Using Raypak values.

0.00328947F^2 for 1.25” pipe per 100 feet.

0.00145349F^2 for 1.5” pipe per 100 foot.

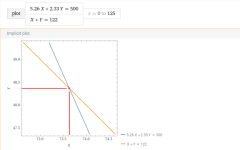

For a 1.25” pipe at 400 CFH, we can estimate the pressure drop in milliinches to be about 526 milliinch per 100 foot of pipe.

For 1.5” pipe at 400 CFH, we can estimate the pressure drop in milliinches to be about 233 milliinch per 100 foot of pipe.

If half the pipe (61 feet) is 1.25” and half the pipe (61 feet) is 1.5”, then the total pressure drop is 0.61 (526 + 233) = 463 milliinches or 0.463”, which would be acceptable.

0.321” for the 1.25” pipe and 0.142” w.c for the 1.5” pipe.

However, I would just follow the manufacturer’s recommendation and do all 1.5” pipe.

If there is ever a warranty issue, you do not want to try to explain this to the manufacturer.