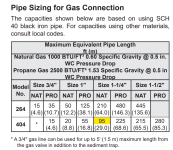

The gas co. said it supplies 700k Btu.

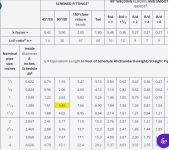

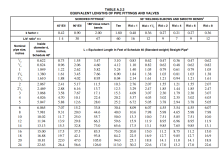

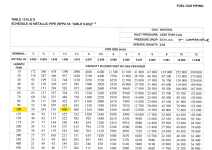

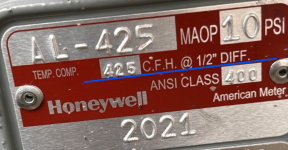

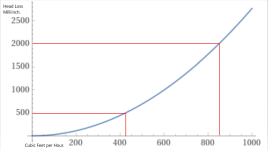

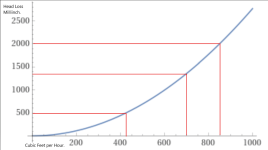

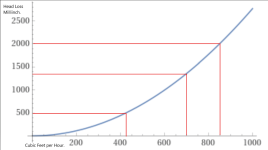

In my calculation, 700 CFH will create a pressure drop of about 1.35" w.c, which I would find unacceptable.

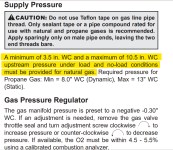

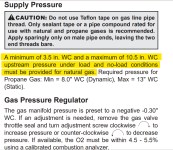

If the Meter input is 7" w.c, then the meter output at 700 CFH will be about 5.65" w.c.

The line will create about 0.5" to about 1.0" w.c loss and the dynamic will be about 4.65" w.c at the gas valve inlet.

The minimum is specified as 3.5" of w.c, so it should be above the minimum.

You need to verify the static and dynamic under full load to verify that the heater is getting the correct gas pressure.

Note: These are just my opinions and they are not professional advice or recommendations.

Do not rely on anything I say.

The gas company is responsible for sizing the meter correctly.

The licensed gas plumber is responsible for installing the gas lines and for verifying the heater is working correctly.

The installer should connect the gas and go through a commissioning process.

Commissioning is where they test run the heater and verify that everything is working correctly.

They should give you a commissioning report to verify that the installation was successfully completed.

The report should note things like gas pressure static and dynamic, stack flue/vent temperature, HX (Heat Exchanger) Flow estimate, all metrics from the control panel like temperature inlet and outlet, flame strength, In/Out Temperature, flow in GPM, any errors, supply voltage, hours, cycles etc.

The commissioning report is the official “Installation Date”.

It should note the name of the company that installed the heater, the name of the technician, the trade license information for the Installer, the inspection information, the permit information etc.

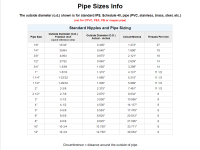

It should contain the design details like type of gas line, size and length.

The Warranty needs to be registered with Raypak as soon as possible.