- May 3, 2007

- 17,865

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Edit - Before reading this article, you may want to first familiarize yourself with this Pool School article on Pump Basics

Hydraulics 101 - Pump Head Curves, Plumbing Head Curves and Operating Points

Hydraulic Head

Static head is the net elevation change of the water which can be either positive or negative and is directly related to the height of the water. So water moving from a higher elevation to a lower elevation has head gain while water moving from a lower elevation to a higher elevation has head loss. For example, a pool solar system installed on a roof and where the panels/pipes are primed and completely filled with water, there is static head loss when the water rises to the roof but then there is also static head gain when the water falls back to the ground. The static head loss on the way up is directly offset by the static head gain on the way down so there is no net static head change due to the fact that the solar is installed on the roof. However, there can be temporary static head loss or gain during the priming process where there is head loss due to the elevation lift but since the return pipe is not yet full of water, there is no static head gain to offset it.

The second component of head is dynamic head loss which is due to the friction loss of water inside of pipes, fittings and other equipment. As water travels through a pipe, the friction against the internal structures reduces pressure. A pool's plumbing system will experience dynamic head loss on both the suction side of the pump and return side of the pump since water is moving through plumbing on both sides. The faster water moves through a pipe, the more head loss there will be. A pool pump adds dynamic head gain to the plumbing system so as to create positive pressure and thus water flow through the pipes. The dynamic head loss in the pipes then reduces the pressure until the water returns to the pool where the pressure is once again at 0 PSIr (PSI relative to atmospheric pressure).

A common mistake made by some that are new to hydraulics is to assume that the head loss in plumbing is equal to the length of pipe since they both use the same units. While the dynamic head loss in plumbing is related to the length of pipe, it does not equal it. Addition factors are necessary to calculate the head loss in plumbing and can be quite challenging to accomplish.

In summary, pumps and elevation drops add head to a plumbing system while elevation rises, pipes, fittings, valves, filter, heaters, etc. subtract head from a system. For a swimming pool, the total head loss is always equal to the pump's head gain since the water is returned to the same atmospheric pressure as where it came from.

Pump Head Curves

A residential pool pump is actually made up of two separate "machines". The first machine is often called the "wet end" and this is the part that actually pumps the water and converts rotational energy into flow and pressure. The second machine is the electric motor which converts electrical energy into rotational energy and drives the wet end. Together, these two machines make up a residential pool pump.

Most manufactures of pumps include head curves in their pump manuals and/or sell sheets. The curves have two axes, Feet of Head vs. Gallons per Minute (GPM). Feet of head is used instead of PSI because a centrifugal pump will always deliver the same head for any liquid of any density while the PSI will be different for different liquids and/or densities so traditionally, manufactures have used head instead of PSI.

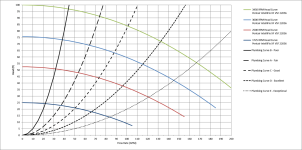

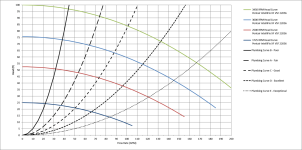

The head curve is useful in determining the flow rate of the pump if the head loss of the plumbing system is known. Below is an example of a head curve for the Pentair Intelliflo published by the manufacture.

The maximum head of the pump is reached when the flow rate is near zero GPM and at full RPM. This is equivalent to an equal length of open ended pipe straight up in the air. The pump will fill the pipe to the top but no water will spill out.

This particular chart also shows that the energy use of a pump is fairly linear with the flow rate. This is true for all residential pool pumps. The higher the flow rate of the pump, the more energy that is used. However, flow rates tend to increase faster than the energy use which is why the energy factor of the pump as measured as gallons per Watt-hr, increases with increasing flow rate effectively reducing the energy consumption. However, there is a flow rate limit that a pump can produce which is called "run out" but most pool installations will never reach this limit because there is always at least some plumbing head loss.

Pump Speed

Typically, a single speed pump will operate at around 3450 RPM. But there can be significant advantages when running at lower RPM. The pump affinity equations can be used to determine how a pump's characteristics (e.g. head curve) will change with speed. So if the flow rate, head or hydraulic HP is known for any one speed A, it can be calculated for another speed B using the following formulas.

For example, low speed of a two speed pump has about 1/2 the flow rate as high speed and the affinity equations tell us that it requires only 1/8th the power of high speed. Unfortunately, two speed motors lose about half their efficiency at low speed so the energy use is only about 1/4th of high speed but still significant.

Current generation variable speed pumps provide even more cost savings over their two speed counterparts. Plus, given the range in RPM settings, the pump can be optimized for the given pool plumbing. The flexibility of a variable speed pump ensures a maximum energy factor for nearly any operating condition. Plus, current US DOE regulations pretty much dictate the exclusive use of VS pumps. Larger single speed and two speed pumps (>0.711 HHP) can no longer be manufactured in the US with few exceptions.

Plumbing Head Curves

Much like a pump, a plumbing system also has a head curve which is usual identified as a "Plumbing Curve" or a "System Curve". And much like a pump's head curve, the plumbing curve is parabolic in shape and when plotted over a pump's head curve, crosses the pump's head curve at a single point which is called the "operating point". The plumbing curve of any plumbing system may be approximated by this simple formula:

Head (ft) = k * GPM^2

Where k is the plumbing curve constant that is dependent on the configuration of the plumbing system. The plumbing curve "standards" are defined as:

The following chart shows an example of a pump head curve along with several plumbing curves overlayed on top. The intersection of the plumbing curve with the pump's head curve is defined as the operating point.

Hydraulics 101 - Pump Head Curves, Plumbing Head Curves and Operating Points

Hydraulic Head

Hydraulic Head is a term that originated in the water distribution industry and relates to the "head" or top of the water level. It is also another way of expressing the amount of pressure (PSI=pounds per square inch) lost or gained in a plumbing system. For example, a pool pump adds head or pressure to the plumbing system while the friction loss in piping and equipment removes head or decreases pressure in system. In addition, there are two basic types of head loss and gain in any plumbing system; Static Head and Dynamic Head.In fluid dynamics, head is a concept that relates the energy in an incompressible fluid to the height of an equivalent static column of that fluid. From Bernoulli's Principle, the total energy at a given point in a fluid is the energy associated with the movement of the fluid, plus energy from pressure in the fluid, plus energy from the height of the fluid relative to an arbitrary datum. Head is expressed in units of height such as meters or feet. - Wikipedia

Static head is the net elevation change of the water which can be either positive or negative and is directly related to the height of the water. So water moving from a higher elevation to a lower elevation has head gain while water moving from a lower elevation to a higher elevation has head loss. For example, a pool solar system installed on a roof and where the panels/pipes are primed and completely filled with water, there is static head loss when the water rises to the roof but then there is also static head gain when the water falls back to the ground. The static head loss on the way up is directly offset by the static head gain on the way down so there is no net static head change due to the fact that the solar is installed on the roof. However, there can be temporary static head loss or gain during the priming process where there is head loss due to the elevation lift but since the return pipe is not yet full of water, there is no static head gain to offset it.

The second component of head is dynamic head loss which is due to the friction loss of water inside of pipes, fittings and other equipment. As water travels through a pipe, the friction against the internal structures reduces pressure. A pool's plumbing system will experience dynamic head loss on both the suction side of the pump and return side of the pump since water is moving through plumbing on both sides. The faster water moves through a pipe, the more head loss there will be. A pool pump adds dynamic head gain to the plumbing system so as to create positive pressure and thus water flow through the pipes. The dynamic head loss in the pipes then reduces the pressure until the water returns to the pool where the pressure is once again at 0 PSIr (PSI relative to atmospheric pressure).

A common mistake made by some that are new to hydraulics is to assume that the head loss in plumbing is equal to the length of pipe since they both use the same units. While the dynamic head loss in plumbing is related to the length of pipe, it does not equal it. Addition factors are necessary to calculate the head loss in plumbing and can be quite challenging to accomplish.

In summary, pumps and elevation drops add head to a plumbing system while elevation rises, pipes, fittings, valves, filter, heaters, etc. subtract head from a system. For a swimming pool, the total head loss is always equal to the pump's head gain since the water is returned to the same atmospheric pressure as where it came from.

Pump Head Curves

A residential pool pump is actually made up of two separate "machines". The first machine is often called the "wet end" and this is the part that actually pumps the water and converts rotational energy into flow and pressure. The second machine is the electric motor which converts electrical energy into rotational energy and drives the wet end. Together, these two machines make up a residential pool pump.

Most manufactures of pumps include head curves in their pump manuals and/or sell sheets. The curves have two axes, Feet of Head vs. Gallons per Minute (GPM). Feet of head is used instead of PSI because a centrifugal pump will always deliver the same head for any liquid of any density while the PSI will be different for different liquids and/or densities so traditionally, manufactures have used head instead of PSI.

The head curve is useful in determining the flow rate of the pump if the head loss of the plumbing system is known. Below is an example of a head curve for the Pentair Intelliflo published by the manufacture.

The maximum head of the pump is reached when the flow rate is near zero GPM and at full RPM. This is equivalent to an equal length of open ended pipe straight up in the air. The pump will fill the pipe to the top but no water will spill out.

This particular chart also shows that the energy use of a pump is fairly linear with the flow rate. This is true for all residential pool pumps. The higher the flow rate of the pump, the more energy that is used. However, flow rates tend to increase faster than the energy use which is why the energy factor of the pump as measured as gallons per Watt-hr, increases with increasing flow rate effectively reducing the energy consumption. However, there is a flow rate limit that a pump can produce which is called "run out" but most pool installations will never reach this limit because there is always at least some plumbing head loss.

Pump Speed

Typically, a single speed pump will operate at around 3450 RPM. But there can be significant advantages when running at lower RPM. The pump affinity equations can be used to determine how a pump's characteristics (e.g. head curve) will change with speed. So if the flow rate, head or hydraulic HP is known for any one speed A, it can be calculated for another speed B using the following formulas.

- GPM B = GPM A * (RPM B / RPM A)

- Head B = Head A * (RPM B / RPM A) ^ 2

- Hydraulic HP B = Hydraulic HP A * (RPM B / RPM A) ^ 3

For example, low speed of a two speed pump has about 1/2 the flow rate as high speed and the affinity equations tell us that it requires only 1/8th the power of high speed. Unfortunately, two speed motors lose about half their efficiency at low speed so the energy use is only about 1/4th of high speed but still significant.

Current generation variable speed pumps provide even more cost savings over their two speed counterparts. Plus, given the range in RPM settings, the pump can be optimized for the given pool plumbing. The flexibility of a variable speed pump ensures a maximum energy factor for nearly any operating condition. Plus, current US DOE regulations pretty much dictate the exclusive use of VS pumps. Larger single speed and two speed pumps (>0.711 HHP) can no longer be manufactured in the US with few exceptions.

Plumbing Head Curves

Much like a pump, a plumbing system also has a head curve which is usual identified as a "Plumbing Curve" or a "System Curve". And much like a pump's head curve, the plumbing curve is parabolic in shape and when plotted over a pump's head curve, crosses the pump's head curve at a single point which is called the "operating point". The plumbing curve of any plumbing system may be approximated by this simple formula:

Head (ft) = k * GPM^2

Where k is the plumbing curve constant that is dependent on the configuration of the plumbing system. The plumbing curve "standards" are defined as:

- Curve-A which represents fairly restrictive plumbing typical of an AG pool or an IG pool with 1.5" pipe size. k = 0.0167

- Curve-B which represents extremely high head loss conditions. Not many pools would fall in this category. k = 0.05

- Curve-C which represents less restrictive plumbing typical of pools using 2" pipe size. k = 0.0082

- Curve-D which represents less restrictive plumbing typical of pools using 2.5" pipe size. k = 0.0041

- Curve-E which represents less restrictive plumbing typical of pools using 3" pipe size. k = 0.00205

The following chart shows an example of a pump head curve along with several plumbing curves overlayed on top. The intersection of the plumbing curve with the pump's head curve is defined as the operating point.

Last edited: